Method for repairing leaked coiled-material water-proof roof

A construction method and technology for coiled materials, which are applied in building maintenance, roof insulation materials, construction, etc., can solve the problems of unreasonable use of materials, improper repair methods, and poor repair effects, and achieve a wide range of use and good economy. Benefit and social benefit, systematic and reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

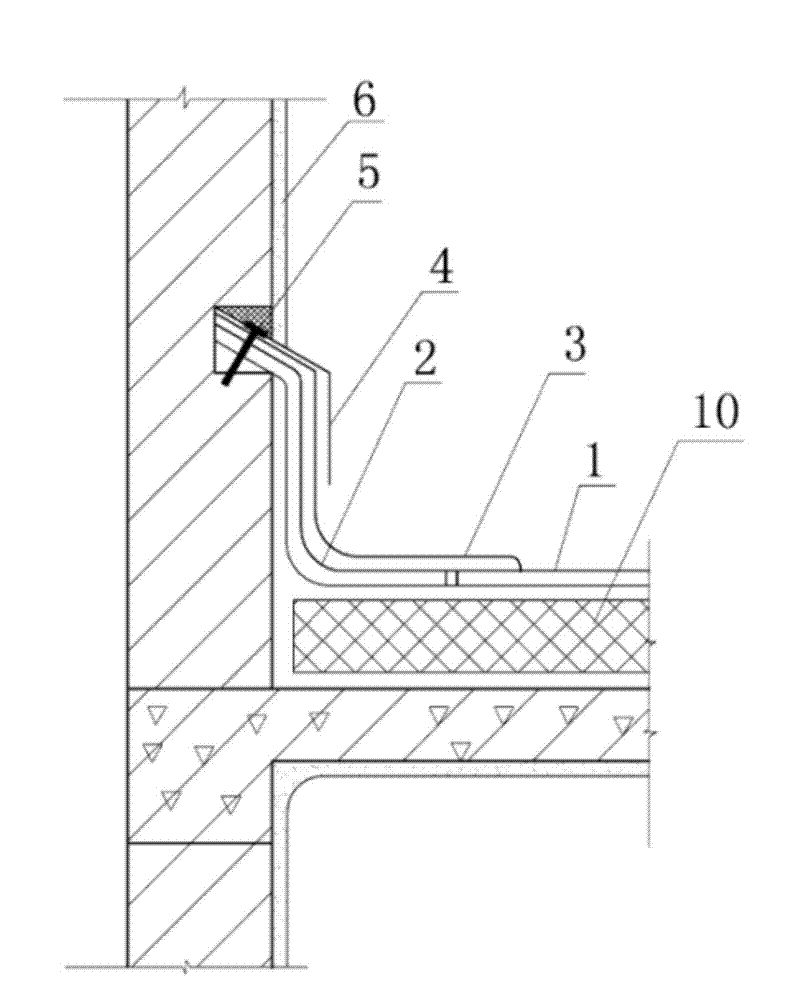

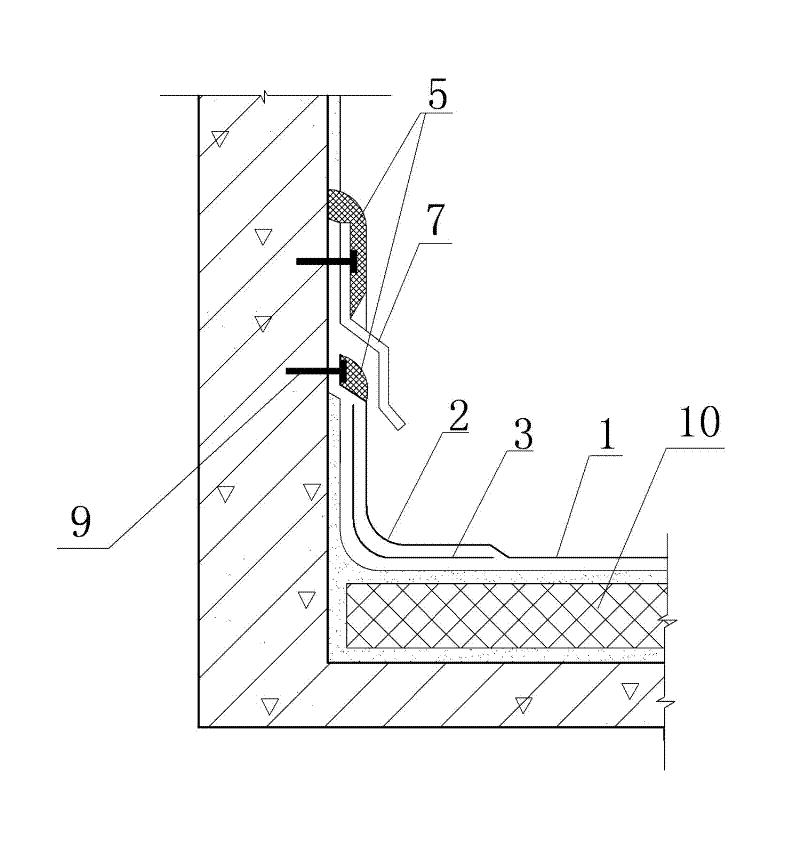

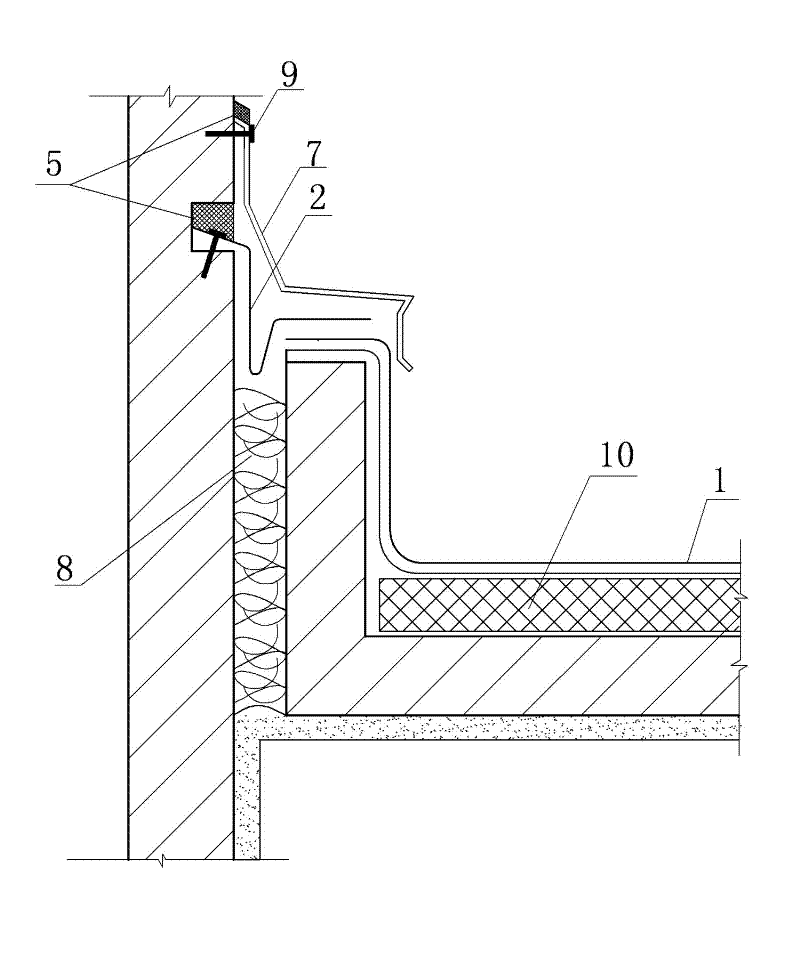

[0030] Example 1 : Construction method for leak repair of membrane waterproof roof

[0031] The method includes: leak investigation, repair plan design, grass-roots treatment, detailed repair, large-scale repair, water storage test, management and maintenance and other processes.

[0032] (1) Leak investigation

[0033] The leak site investigation steps are as follows:

[0034] (1) Investigation content: analyze the environment around the location of the project, the use conditions, and the impact of climate change on the project; find the leak point, determine the location and current situation of the leakage water; the change law of the leakage water; the quality of the waterproof layer at the leakage site Current status and degree of damage; current status of detailed waterproofing; analysis of the cause of leakage, scope of influence, evaluation of structural safety, energy conservation of the outer enclosure structure and damage to other functions; submit a written rep...

Embodiment 2

[0085] Example 2 : Waterproof roof leakage repair construction method

[0086] The construction method is the same as that of Example 1, except that the coils used are synthetic polymer waterproof coils, the coating is sprayed polyurea waterproof coating, and the sealing material is butyl rubber waterproof sealing tape.

Embodiment 3

[0087] Example 3 : Construction method is identical with embodiment 1, difference is:

[0088] The membrane used is waterproof membrane without asphalt, the coating is sprayed polyurea waterproof coating, and the sealing material is butyl rubber waterproof sealing tape.

[0089] The specific proportion of the waterproof membrane without asphalt is as follows in parts by weight: 65 parts of rosin, 50 parts of vegetable oil, 40 parts of styrene-butadiene-styrene block copolymer, and 10 parts of talcum powder. Production method: use heat conduction oil heating equipment to heat, first add rosin, add vegetable oil when heated to 160-200 ° C, stir evenly; then add styrene-butadiene-styrene block copolymer, talcum powder, stir evenly That is, the waterproof membrane of the present invention is obtained. The construction method is the same as that of the modified asphalt coil.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com