Electromagnetic drive underground high-power resonant wave displacement device and method

An electromagnetic drive and resonant wave technology, which is applied to vibration generating devices, earthwork drilling, wellbore/well components, etc., can solve the problems of limiting the popularization and application of vibration oil production technology, unstable working conditions, and inconspicuous vibration effects, etc., to achieve Promote the effect of comprehensive oil displacement, facilitate control and adjustment, and improve energy utilization and work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

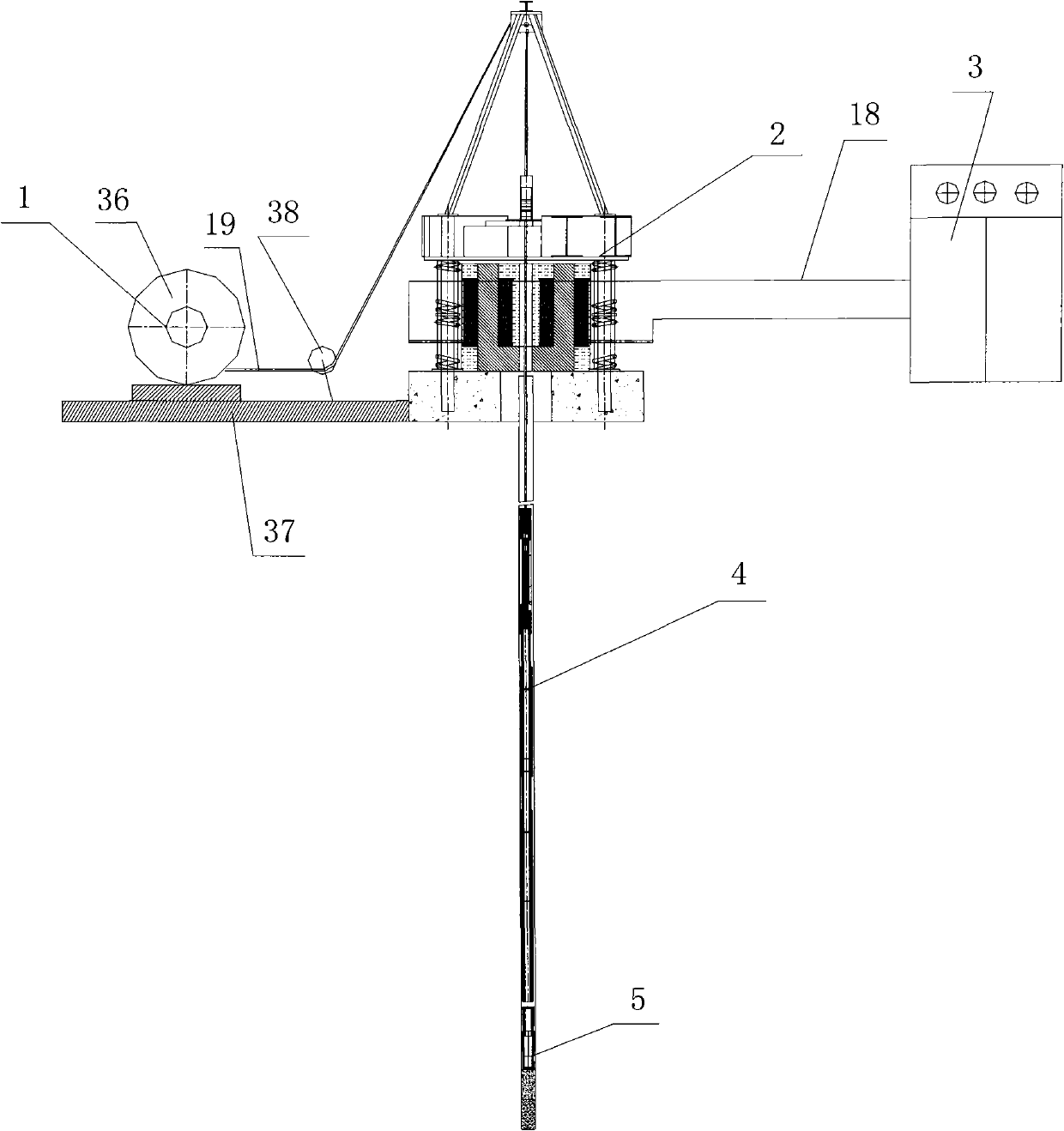

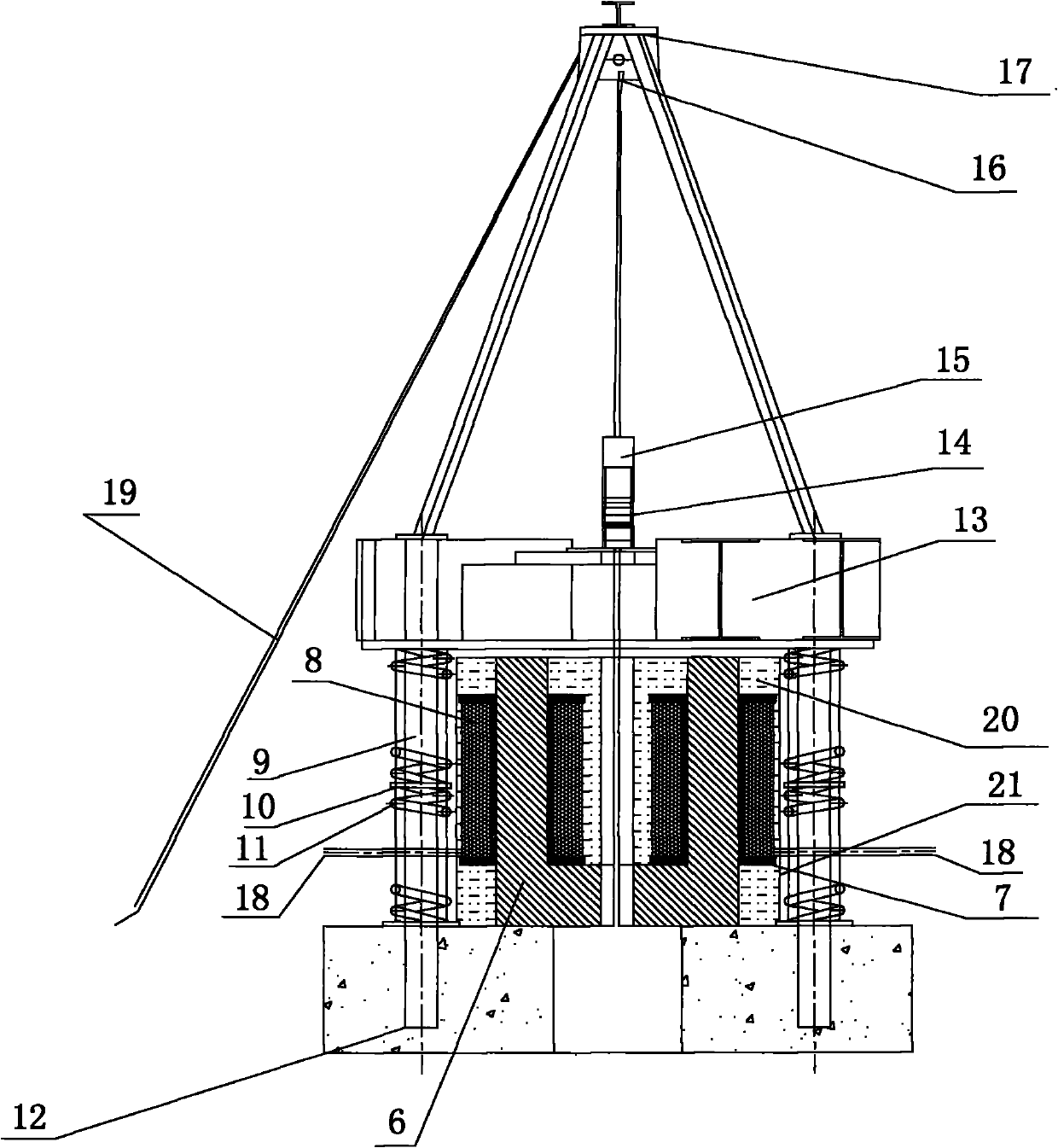

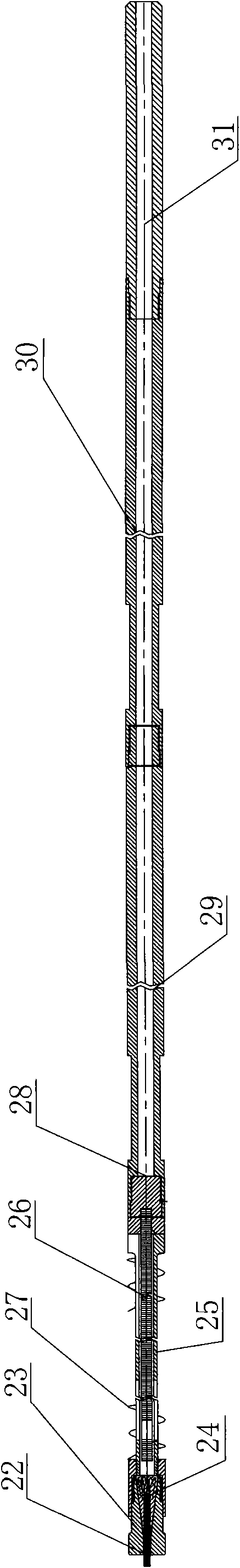

[0048] Such as figure 1 , figure 2 An electromagnetically driven downhole high-power harmonic wave flooding device shown includes a ground vibration source 2 arranged directly above the wellhead of the source well, an artificial well bottom 5 arranged at the bottom of the source well, and vertically inserted from top to bottom. The downhole vibrator 4 inserted into the artificial well bottom 5 in the source well, the downhole vibrator 4 is located directly above the artificial well bottom 5 and the ground vibration source 2 is located directly above the downhole vibrator 4 . The ground vibration source 2 is an electromagnetic vibrator that drives the downhole vibrator 4 to vibrate up and down, and the upper end of the downhole vibrator 4 is fixed on a steel wire rope. Described electromagnetic vibrator comprises the vibrating table 13 that synchronously drives downhole vibrator 4 to vibrate up and down during the vibration process, the excitation coil 8-1 connected with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com