High voltage capacitor chamber with adjacent structure

A technology of high-voltage capacitors and regulators, which is applied in the substation/power distribution device shell, substation/switchgear cooling/ventilation, etc., can solve the problems of low ventilation and cooling efficiency, large power consumption, energy loss, etc., and improve ventilation and cooling Improve efficiency, improve safety and reliability, and reduce energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

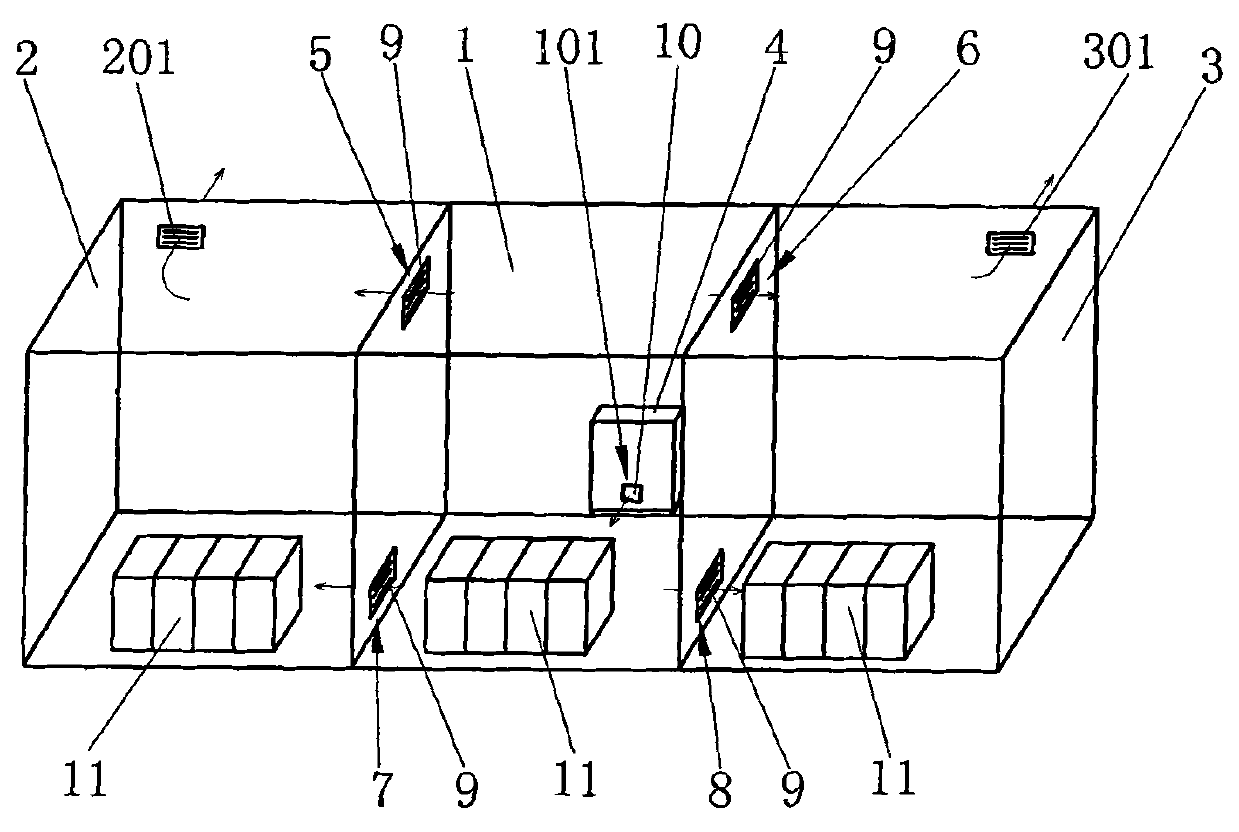

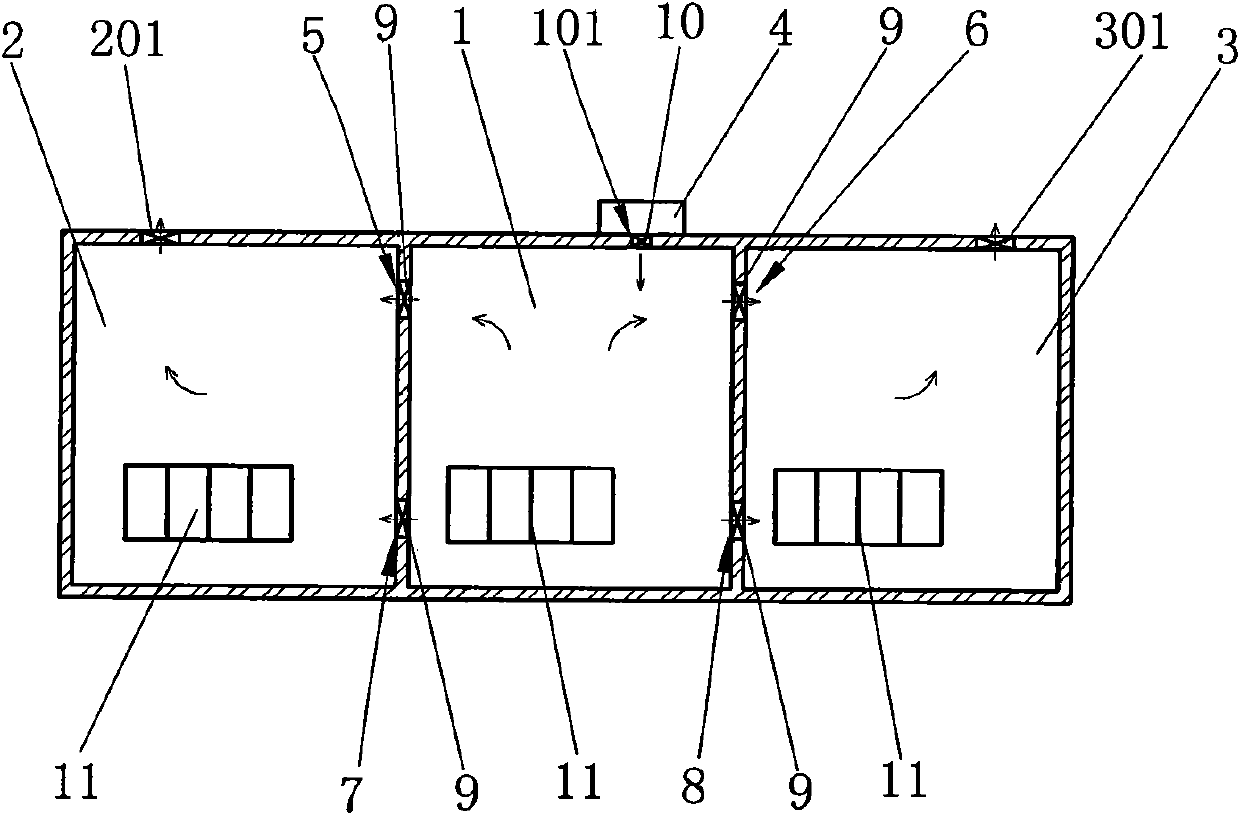

[0015] The present invention comprises at least three machine rooms connected adjacently on the left and right sides, high-voltage capacitors are arranged in the machine room, and the number of rooms in the machine room is determined according to actual needs, such as figure 1 , 2 As shown, in this embodiment, there are three machine rooms adjacently connected to the left and right. The first machine room 1 is the machine room in the middle, and its lower part is provided with an air inlet 101; the second machine room 2 is located on the left side of the first machine room 1, and its upper part An air outlet 201 is provided, and the third machine room 3 is located on the right side of the first machine room 1, and an air outlet 301 is provided on the upper part thereof; The outside of the first computer room 1 is provided with an intelligent temperature-controlled ventilation regulator 4 that supplies air to the computer room. The air outlet of the intelligent temperature-cont...

Embodiment 2

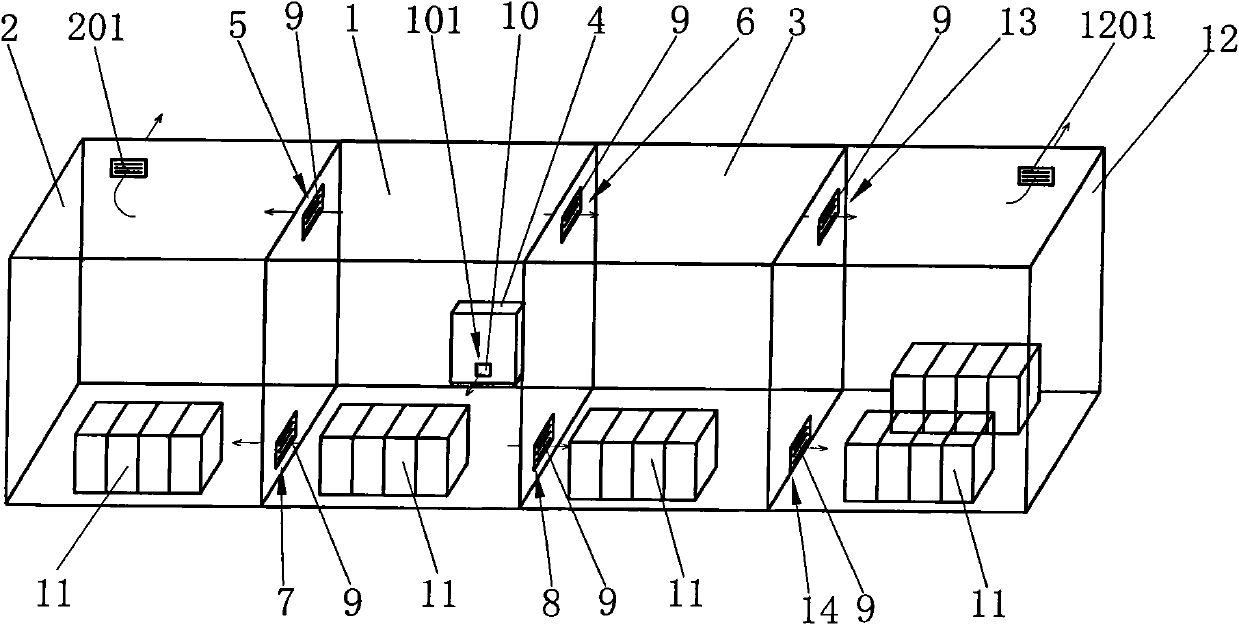

[0019] Such as image 3 As shown, in this embodiment, there are four machine rooms adjacently connected to the left and right. The first machine room 1 is a machine room located in the middle, and the lower part is provided with an air inlet 101; the second machine room 2 is located on the left side of the first machine room 1. The upper part is provided with an air outlet 201, and the lower part of the partition wall between the first machine room 1 and the second machine room 2 is provided with an air inlet communication port 7, and the upper part of the partition wall between the first machine room 1 and the second machine room 2 is air outlet. Connecting port 5; the third machine room 3 and the fourth machine room 12 are located on the right side of the first machine room 1, the fourth machine room 12 is the last machine room on the right side of the first machine room 1, and the upper part of the fourth machine room 12 is provided with an air outlet 1201, The lower part o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com