Electromagnetic induction heating device

A technology of electromagnetic induction heating and induction body, applied in the direction of induction heating device, induction heating, coil device, etc., can solve the problems of inseparability, increased workload, labor and time-consuming, etc., to avoid troublesome disassembly and assembly, and improve safety Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

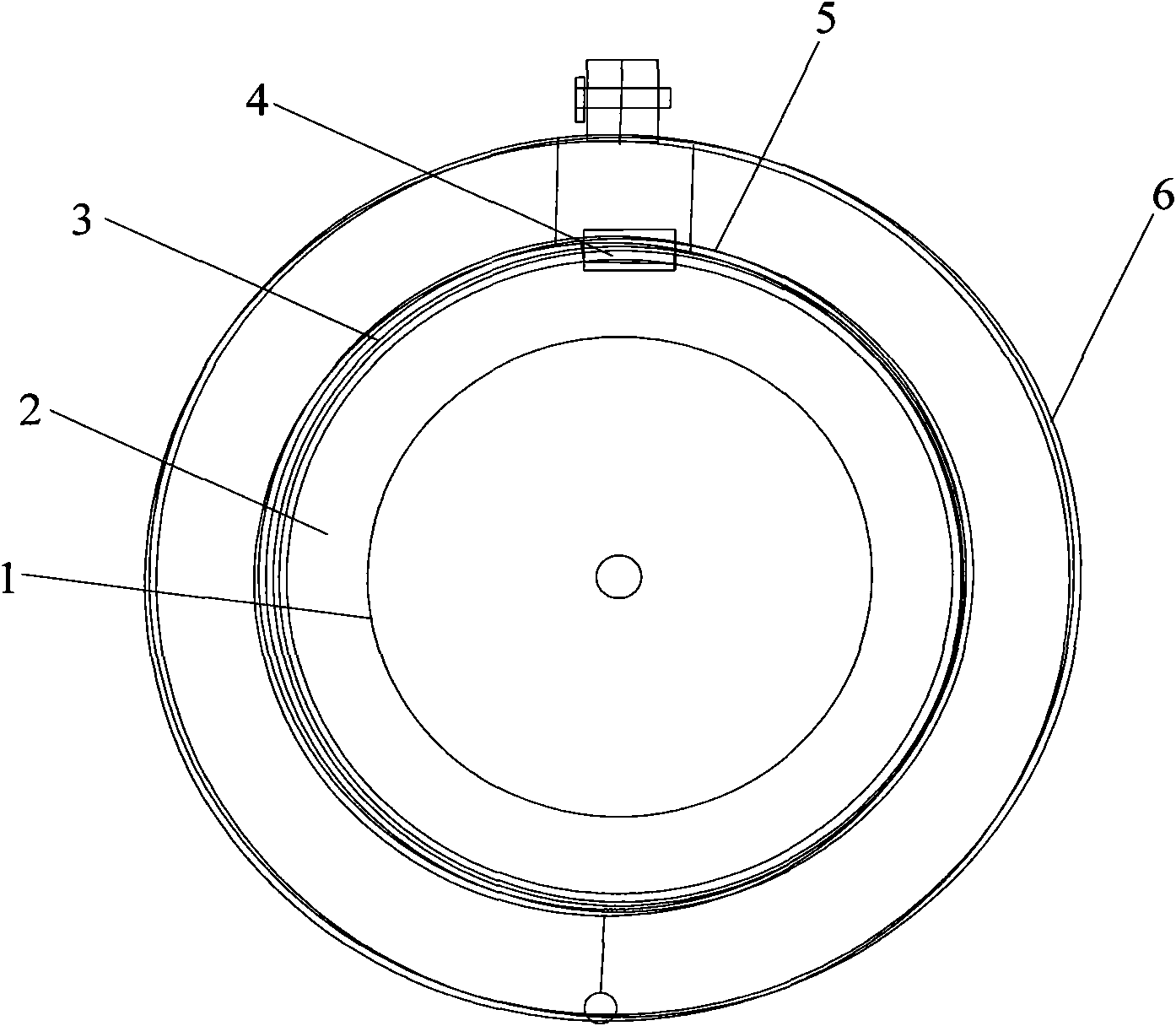

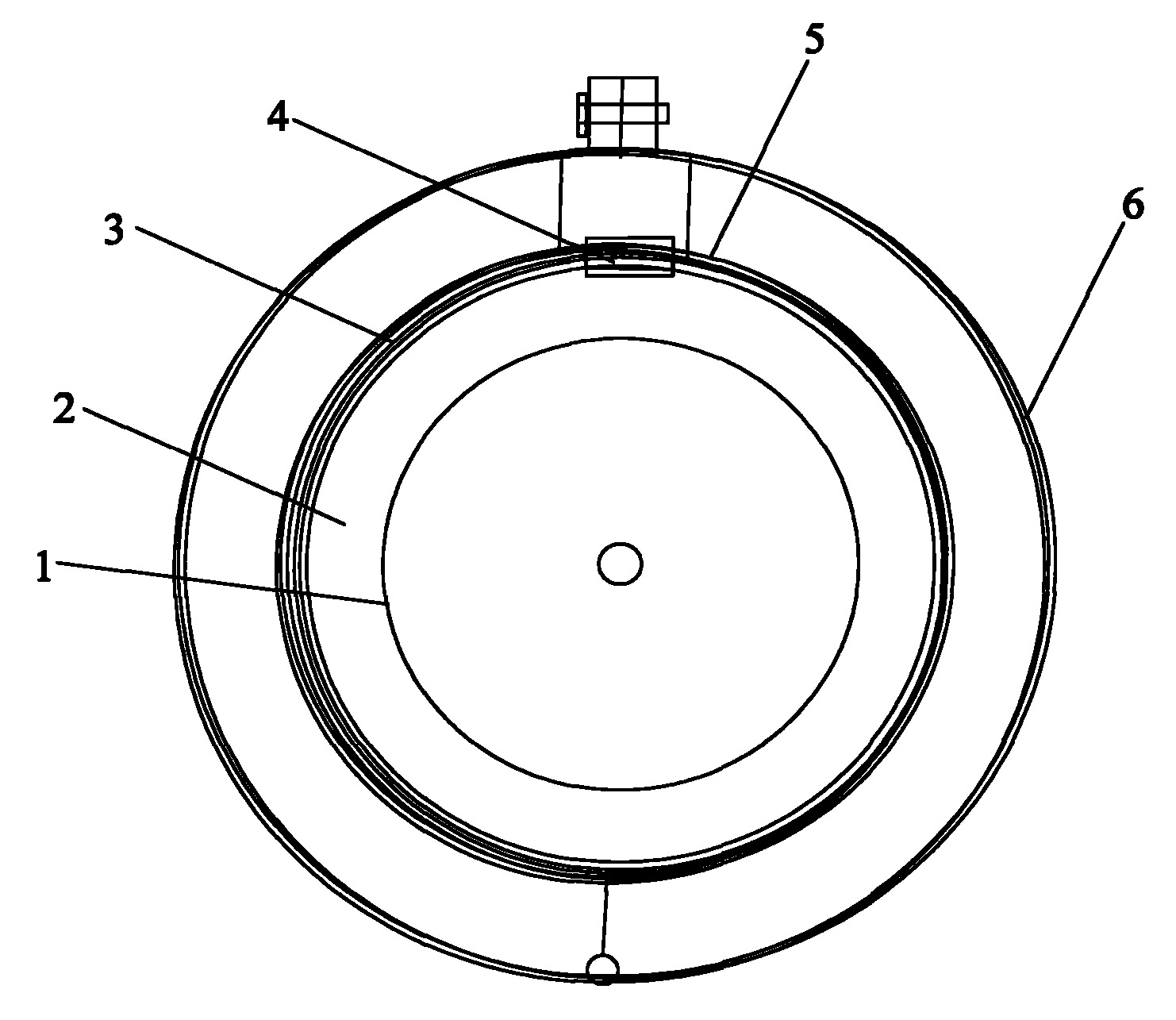

[0020] Such as figure 1 As shown, the electromagnetic induction heating device includes a metal material pipe 1 and an induction body 3. The induction body 3 is formed by an induction coil arranged in the axial direction. On the outer circle of the non-metallic material heat insulation layer 2, the induction coils of each coil of the induction body 3 have a consistent disconnected shape along the axial direction, and the disconnected induction coils of each coil are connected by the connecting buckle 4 correspondingly, and the connecting buckle The two ends respectively have insertion holes for the insertion of the induction coil to form a closed induction coil; the periphery of the induction body 3 is provided with two halves of plastic sheaths 6, including the left plastic sheath and the right plastic sheath, and the left plastic sheath Cooling water chambers are arranged in the two and right plastic sheaths, and the inner walls of the left and right plastic sheaths are prov...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com