Glass assembly cutting method, package manufacturing method, package, piezoelectric vibrator, oscillator, electronic device, and radio-controlled timepiece

A piezoelectric vibrator and packaging technology, which is applied in the field of radio clocks, can solve problems such as rough cut surfaces, low yields, and fractures of wafer joints, and achieve the effects of improving surface accuracy, increasing yields, and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0077] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

[0078] (Piezo Vibrator)

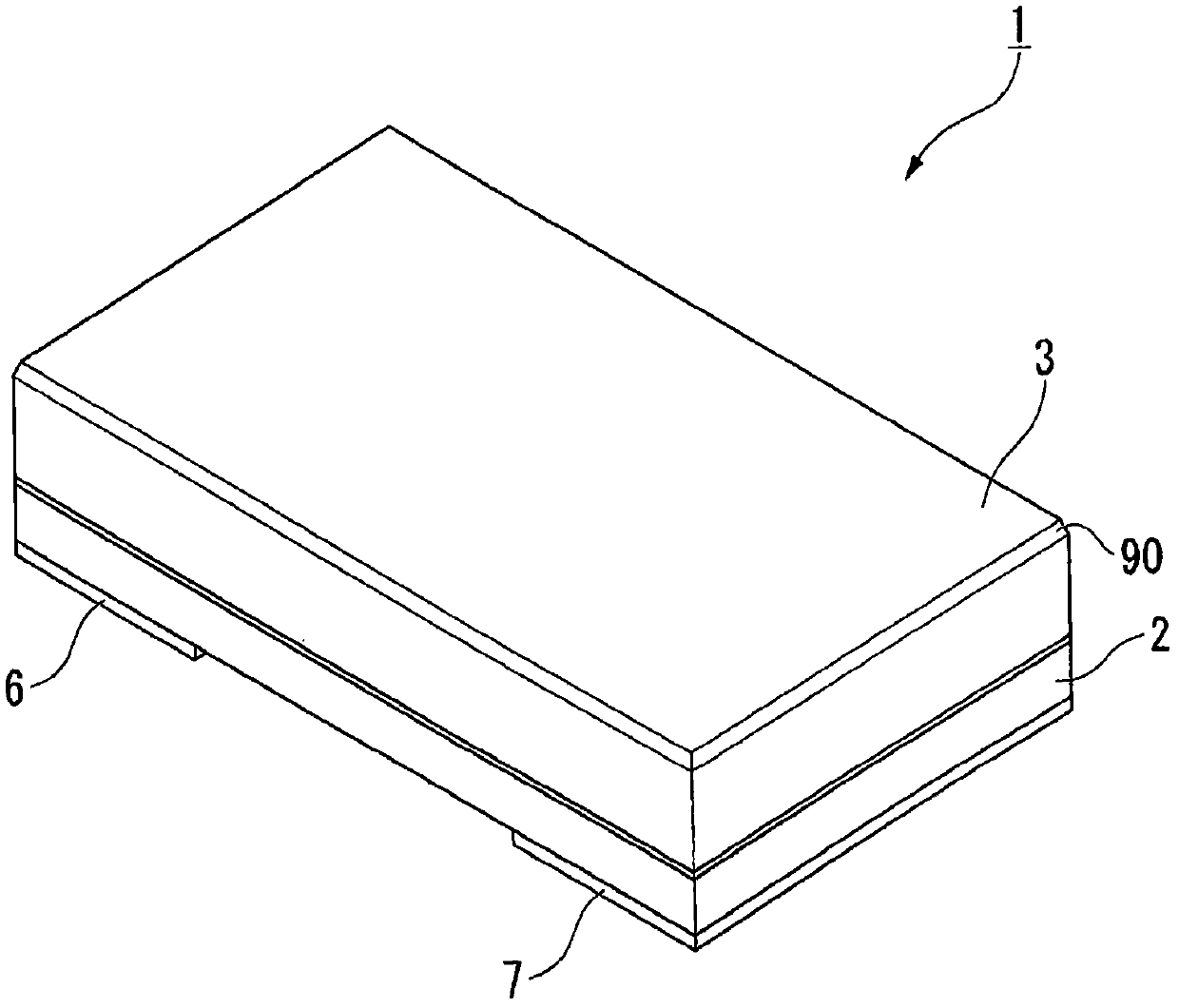

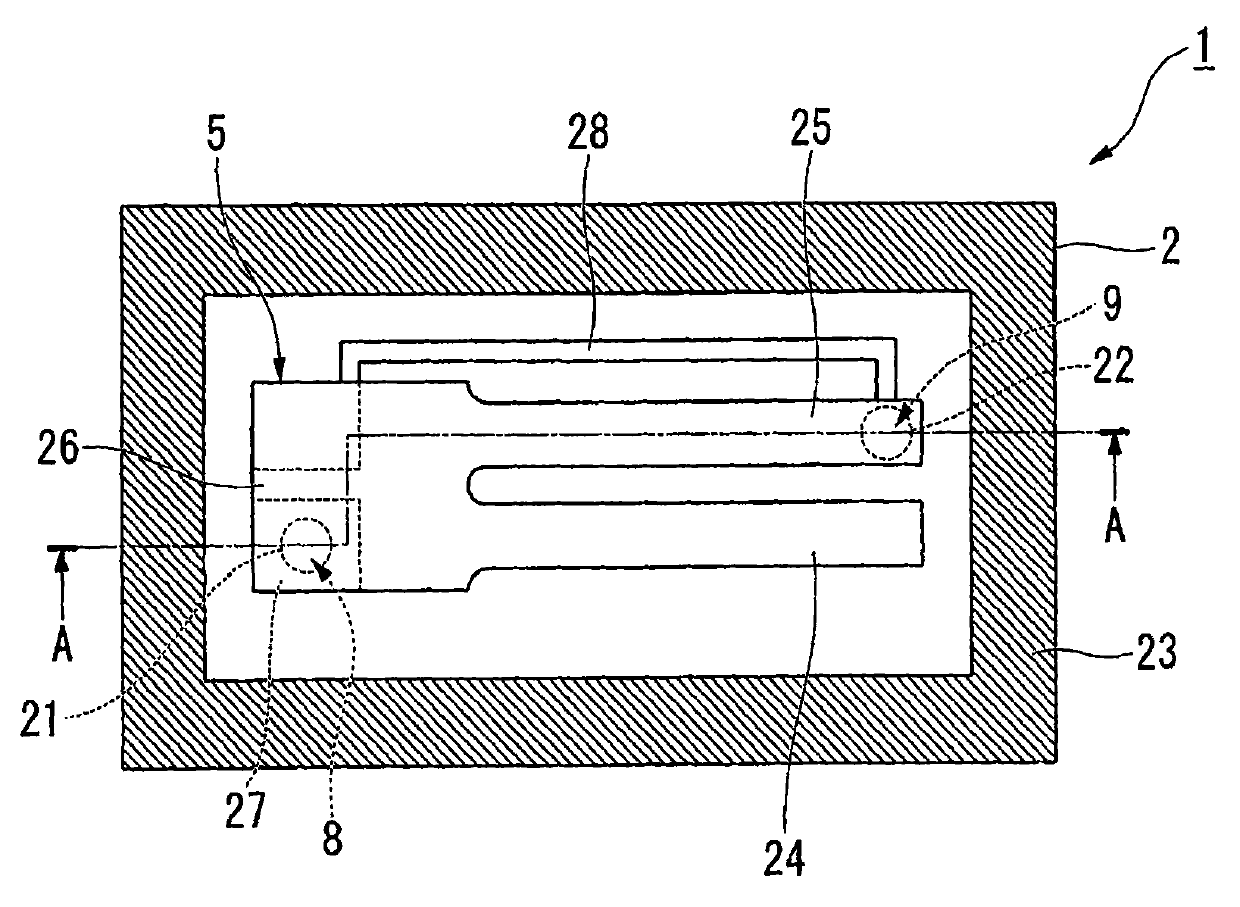

[0079] figure 1 is an external perspective view of the piezoelectric vibrator of this embodiment, figure 2 It is an internal structure diagram of the piezoelectric vibrator, and it is a top view of the piezoelectric vibrating piece with the cover board removed. also, image 3 is along figure 2 A cross-sectional view of the piezoelectric vibrator shown on line A-A, Figure 4 It is an exploded perspective view of the piezoelectric vibrator.

[0080] Such as Figure 1 to Figure 4 As shown, the piezoelectric vibrator 1 is formed in a box shape in which two layers of a base substrate 2 and a lid substrate 3 are stacked, and is a surface-mounted piezoelectric vibrator in which a piezoelectric vibrating reed 5 is housed in a cavity C inside. 1. Further, the piezoelectric vibrating reed 5 is electrically connected to the external electrodes ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com