Method for improving critical cracking thickness of PTFE (Polytetrafluoroethylene) resin emulsion and applications of modified PTFE resin emulsion to non-stick coatings

A technology of polytetrafluoroethylene and resin emulsion, applied in coating, device for coating liquid on surface, surface pretreatment, etc., can solve the problem of small critical cracking film thickness of fluororesin, and improve the critical cracking film thickness , the effect of improving the appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

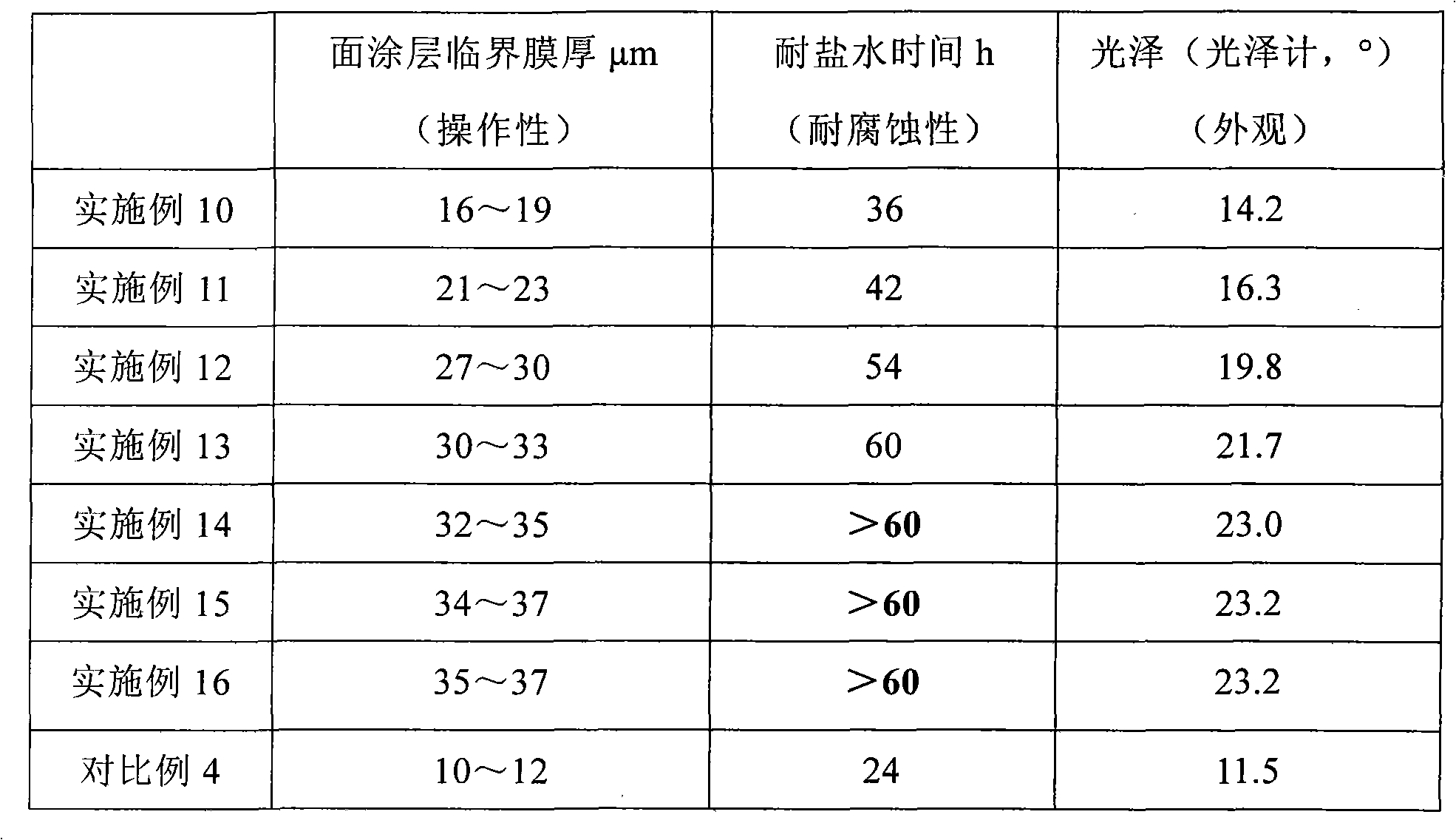

Examples

Embodiment 1

[0049] Get 166.7 parts of PTFE emulsion with 60% content (100 parts of solid content equivalent to PTFE), add 2.5 parts of methyltrimethoxysilane, stir with 10 rpm for 50 minutes, and operate according to the test method of the aforementioned critical film thickness value , the sintering condition is 380° C. for 5 minutes, and the critical film thickness is 15-18 μm.

Embodiment 2

[0051] Get 166.7 parts of PTFE emulsion with 60% content (100 parts of solid content equivalent to PTFE), add 5 parts of methyltrimethoxysilane, stir with 10 rpm for 40 minutes, operate according to the test method of the aforementioned critical film thickness value , the sintering condition is 380° C. for 5 minutes, and the critical film thickness is 20-21 μm.

Embodiment 3

[0053] Get 166.7 parts of PTFE emulsion with a content of 60% (100 parts of solid content equivalent to PTFE), add 7.5 parts of methyltrimethoxysilane, stir for 30 minutes at 10 rpm, and operate according to the test method of the aforementioned critical film thickness value , the sintering condition is 380° C. for 5 minutes, and the critical film thickness is 25-28 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com