Polyurea lubricating grease composition

A polyurea lubricating grease and composition technology, applied in the field of lubricating grease, can solve the problems that are not related to the change of high-temperature cone penetration value of polyurea lubricating grease, that is, high-temperature hardening, etc., and achieve the effect of excellent high temperature resistance and long lubrication life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

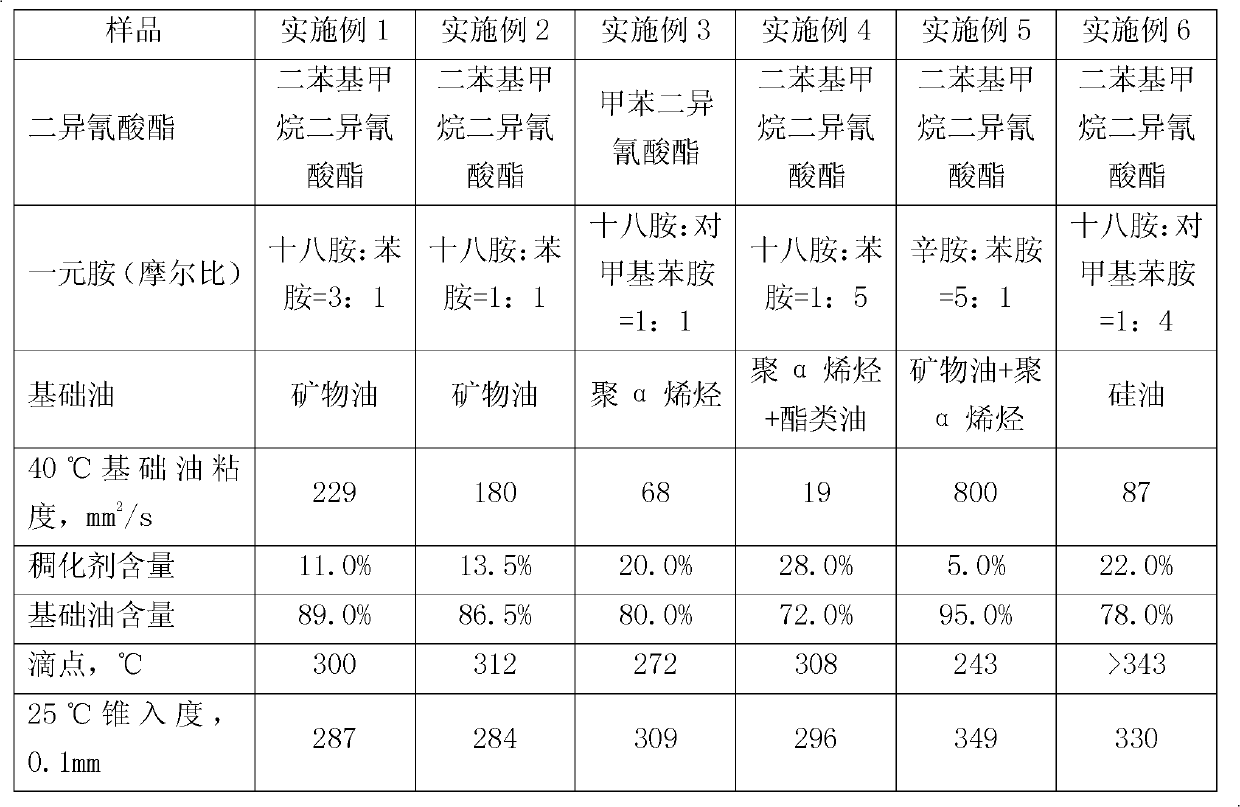

[0033] Typical examples are as follows:

[0034] Put 500 grams of base oil in container A and add all the monoamines, heat up to 60-80°C, put 500 grams of base oil and all the diisocyanate in container B, and heat up to 60-80°C. Then pour the contents of container A into container B and stir the reaction. After the reaction is completed, the temperature of the material is raised to 140-150°C, then cooled down, the additive is added, and the lubricating grease is made after being ground by a three-roller machine. The weight of the diurea thickener formed by the reaction of the monoamine and the diisocyanate accounts for 5-30% of the total weight of the lubricating grease composition. Examples and test results are shown in Table 2, and the material proportions in the table are molar ratios.

[0035] Table 2: Typical Examples

[0036]

[0037]

[0038] Table 2 (continued)

[0039]

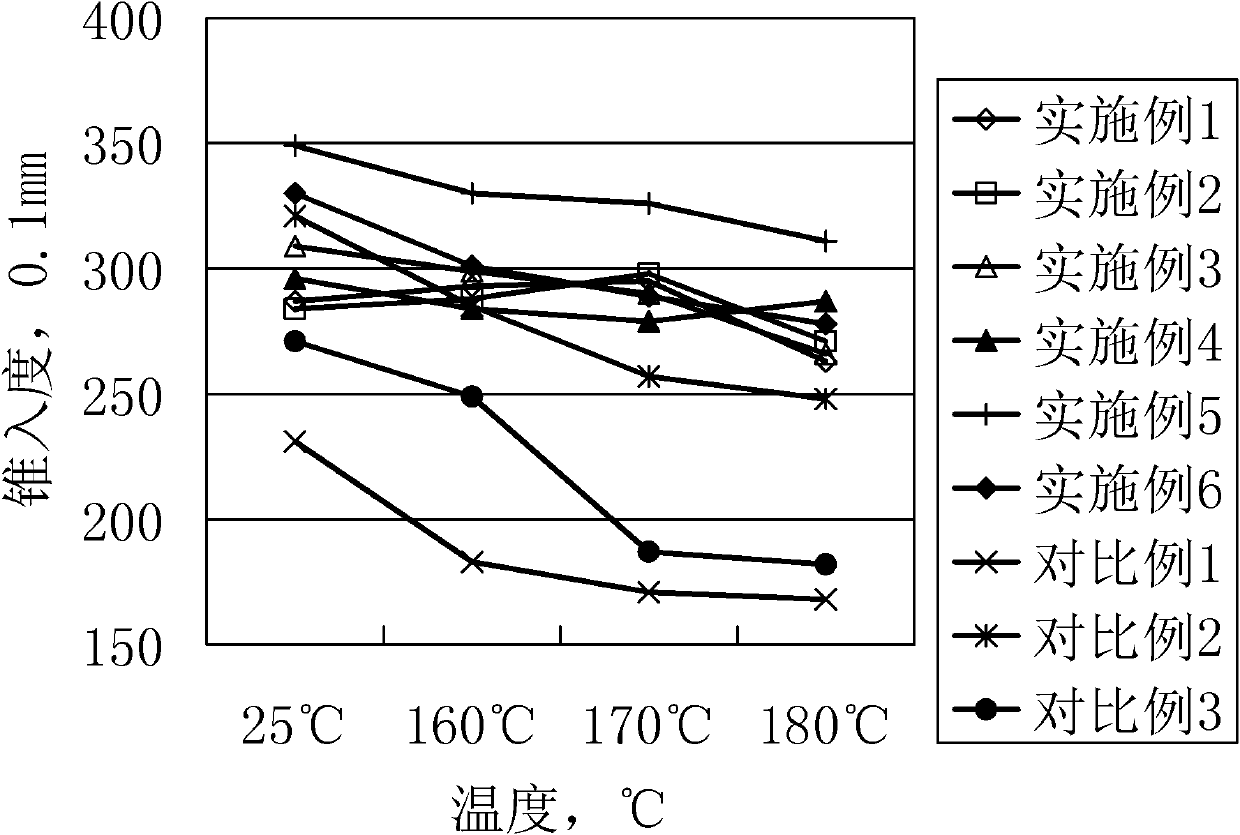

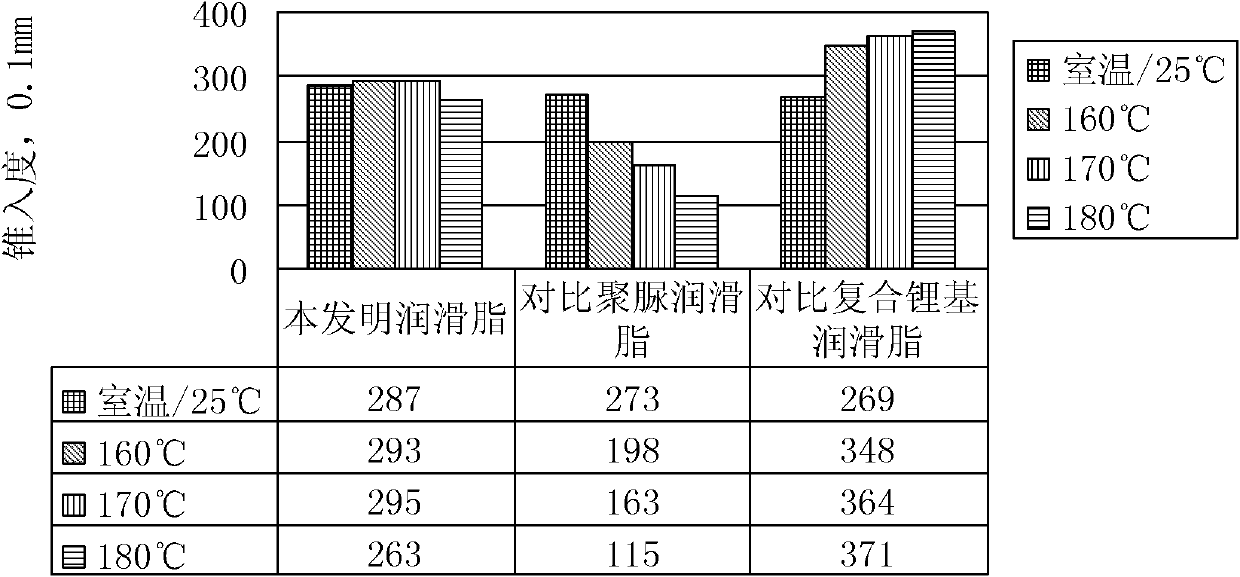

[0040] The comparison of the data in Table 2 shows that the combination of aromatic a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com