Novel screw expanding power machine

A screw expansion and power engine technology, applied in the direction of engine components, machines/engines, intermeshing engines, etc., can solve the problems of low efficiency and reliability, ignore the research and design of screw expansion power, and the overall performance level is not high, so as to achieve improvement Efficiency, ease of assembly and maintenance, and ease of design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

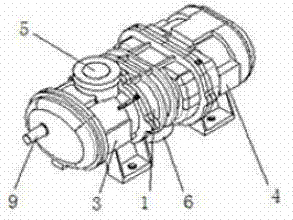

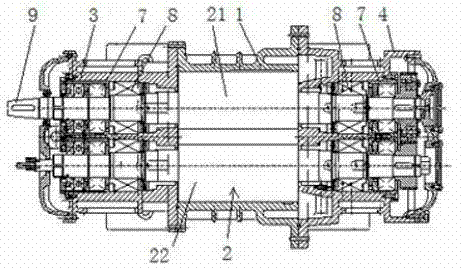

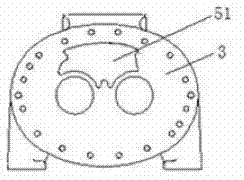

[0024] see figure 1 , figure 2 . The present invention is a novel screw expansion power machine for waste heat recovery working conditions, comprising: cylinder body 1, power machine screw rotor pair 2, suction end seat 3, exhaust end seat 4. The screw rotor pair 2 of the power machine is arranged in the cylinder block, including the male rotor 21 and the female rotor 22 which mesh with each other, and both adopt bilateral symmetrical arc-shaped lines. The suction end seat 3 and the exhaust end seat 4 are respectively arranged at both ends of the cylinder block 1 . Both the suction end seat and the exhaust end seat are designed as a double-wall structure, and cooling water is passed through the interlayer. A suction channel 5 is provided on the suction end seat 3 . An exhaust passage 6 is provided at the lower part of the cylinder block 1 .

[0025] The male rotor 21 and the female rotor 22 of the present invention are carried by bearings, such as figure 2 The central ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com