LED heat radiator and local nickel plating device and local nickel plating method thereof

A technology of LED radiator and local plating, which is applied to lighting devices, cooling/heating devices of lighting devices, lighting and heating equipment, etc., can solve the problems of wasting plating solution, increasing production cost, affecting production efficiency, etc. and pollution, reducing production costs and improving the quality of nickel plating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

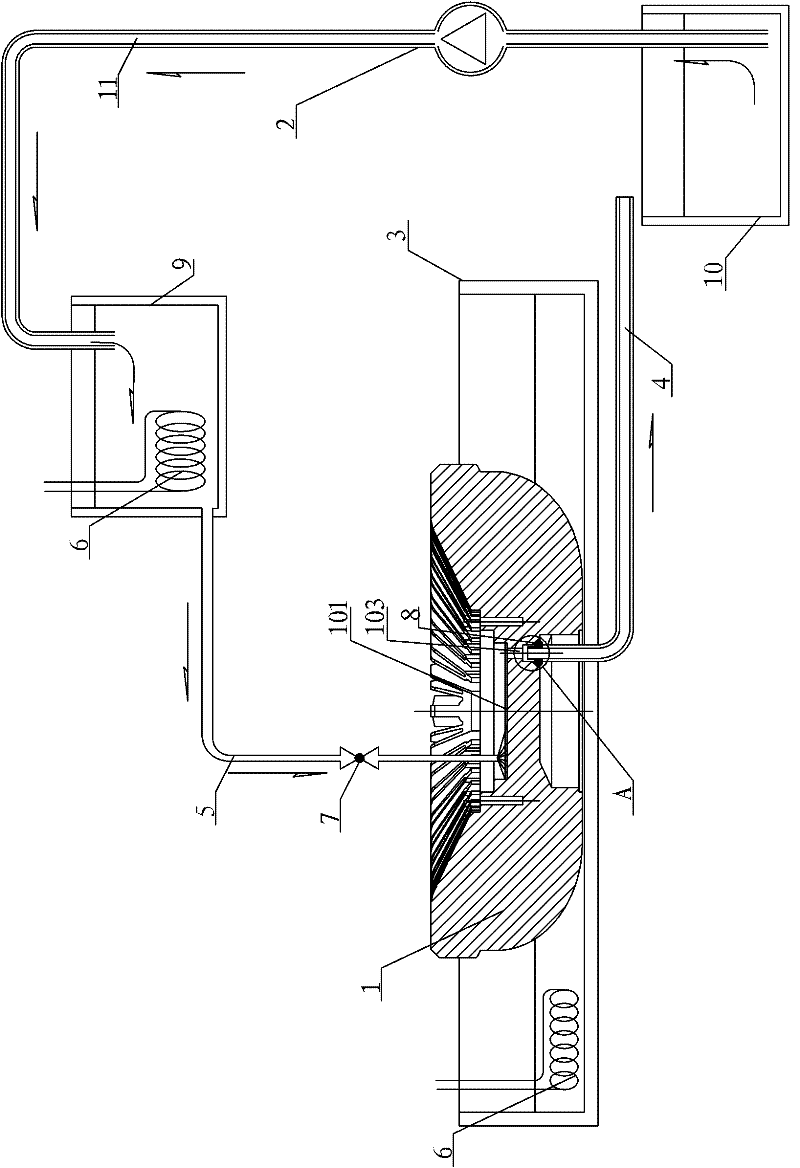

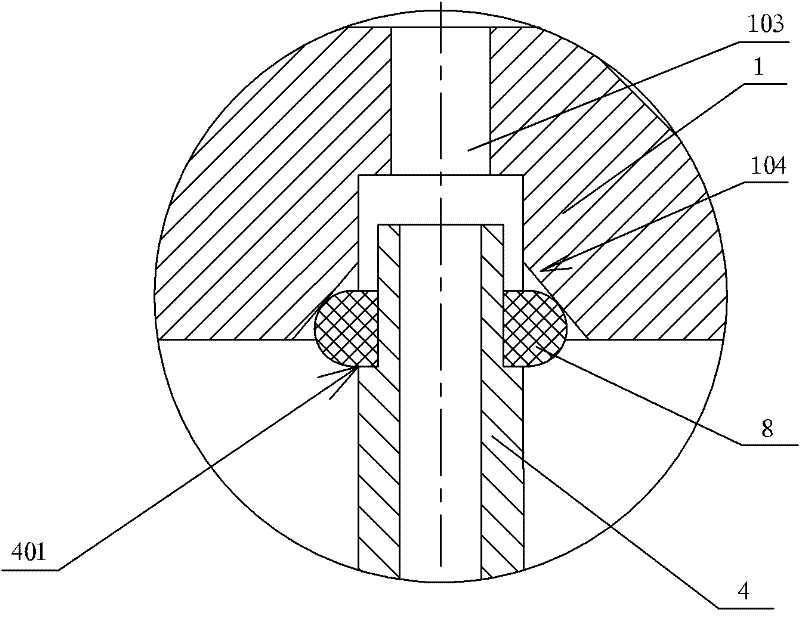

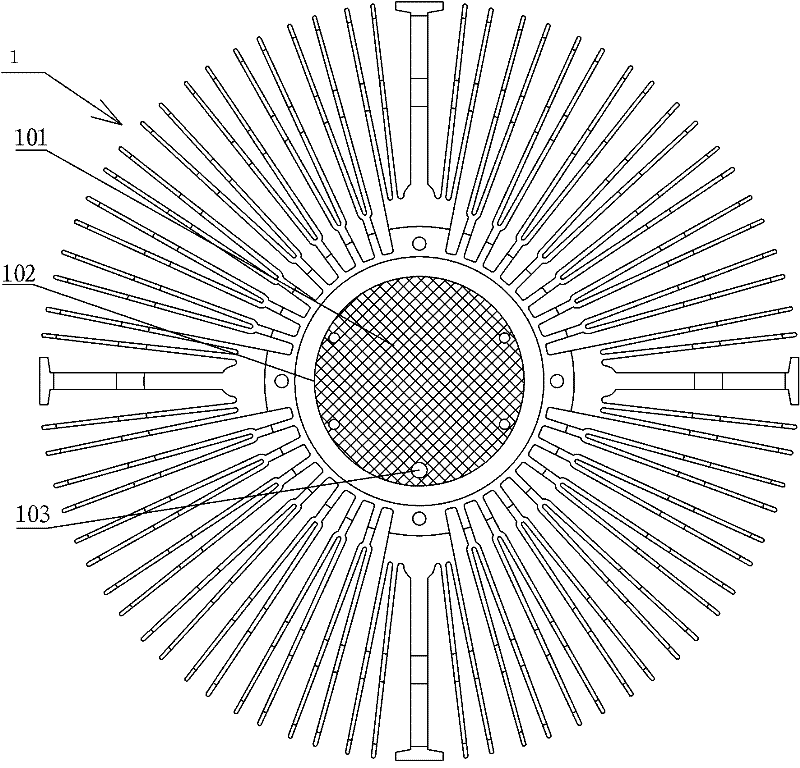

[0026] Such as figure 1 , 2 , 3, LED radiator 1 has a light source heat conduction surface 101, a surrounding frame 102 is arranged around the light source heat conduction surface 101, a liquid outlet channel 103 is provided below the light source heat conduction surface 101, and the lower end of the liquid outlet channel 103 is a tapered hole 104, and the liquid outlet channel 103 is a stepped hole, which is divided into a small-diameter hole located in the upper part and a large-diameter hole located in the lower part. The liquid outlet channel 103 is close to the surrounding frame 102 of the heat conducting surface 101 of the light source, and the taper angle of the taper hole 104 is 80-90 degrees.

[0027] The local nickel plating device of the LED radiator 1 includes a high-level liquid storage tank 9, a low-level liquid storage tank 10 lower than the high-level liquid storage tank 9, an acid-resistant pump 2 for realizing the circulation of the plating solution, and a h...

Embodiment 2

[0033] Embodiment 2: basically the same as Embodiment 1, the difference is that only one liquid storage tank is provided in the local nickel plating device of the light source base 1, the plating solution flows to the liquid storage tank through the liquid return pipe, and the acid-resistant pump 2 extracts the plating solution As for the liquid injection pipe 5, compared with Embodiment 1, the high-level liquid storage tank 9 is reduced, and the structure is simplified, but in the plating solution process, the acid-resistant pump 2 needs to run from time to time.

[0034] The invention can be applied not only to nickel plating, but also to other metal plating films, such as silver plating, cadmium plating and the like.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com