All-in-one machine for constant temperature and humidity and air processing

An air treatment, constant temperature and humidity technology, applied in air conditioning systems, space heating and ventilation, space heating and ventilation details, etc., can solve problems such as increased initial investment, increased operating costs, and no recycling, and achieve operating costs. Low profile, small footprint and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but the present invention is not limited to the scope of the described embodiments.

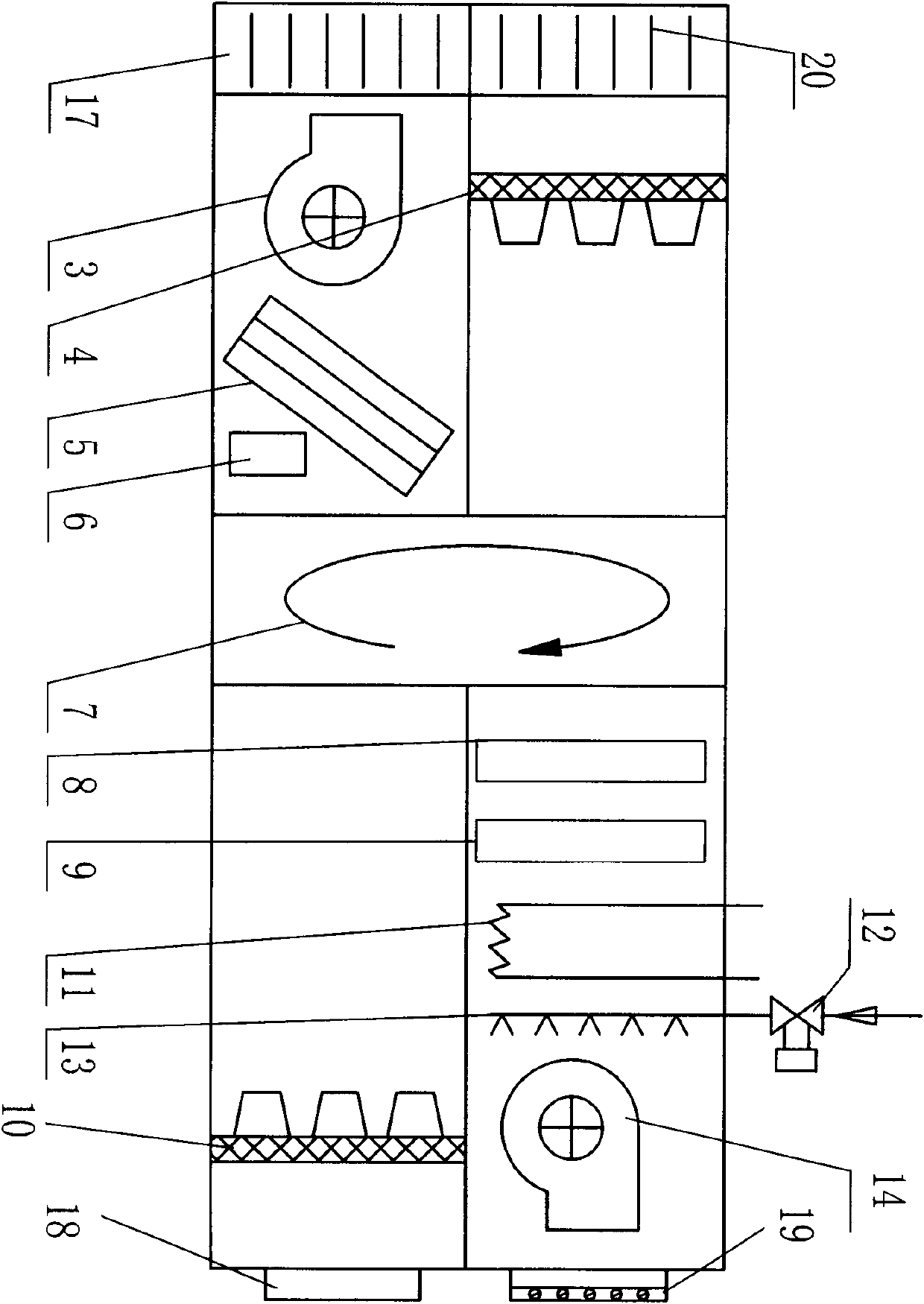

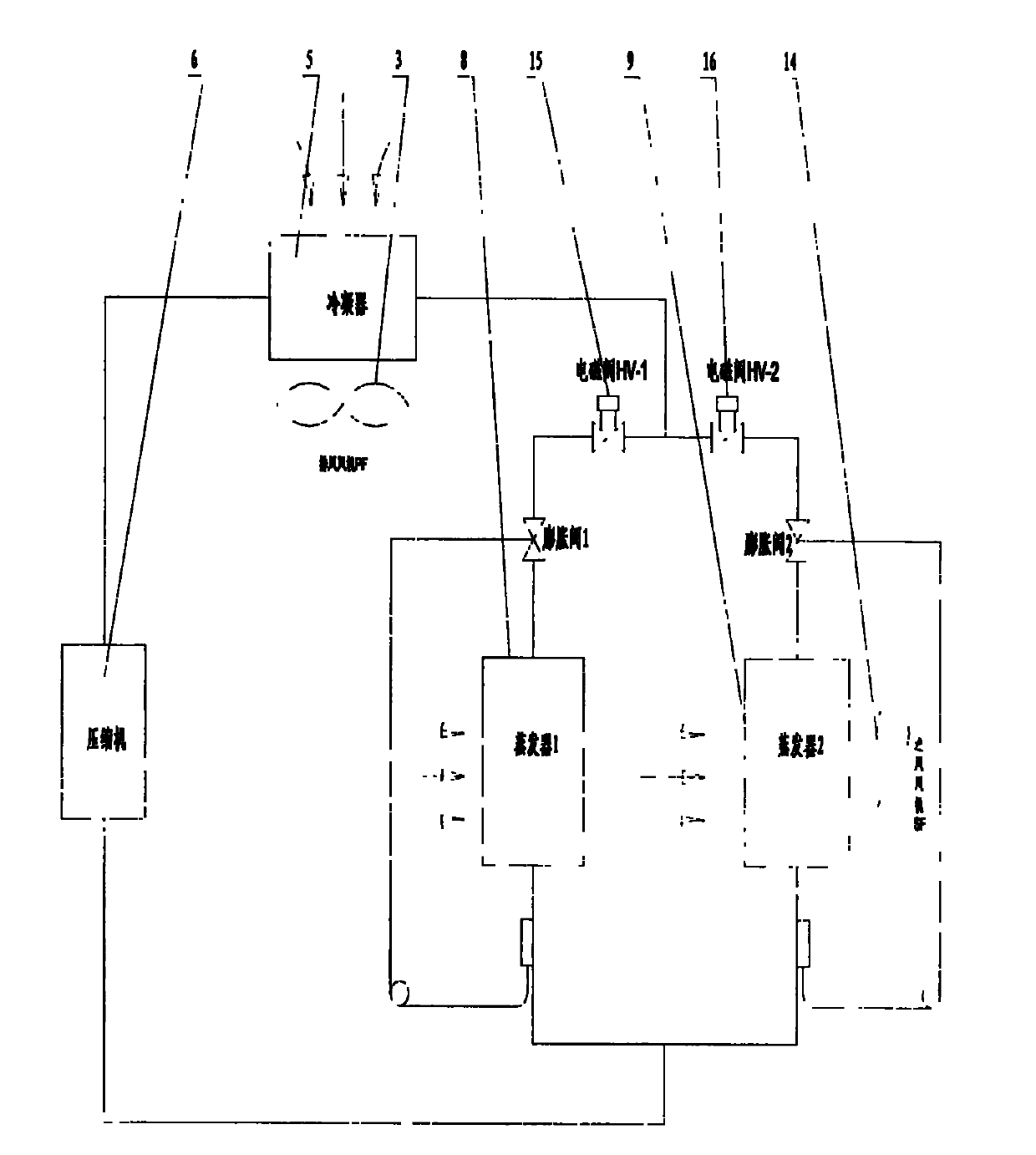

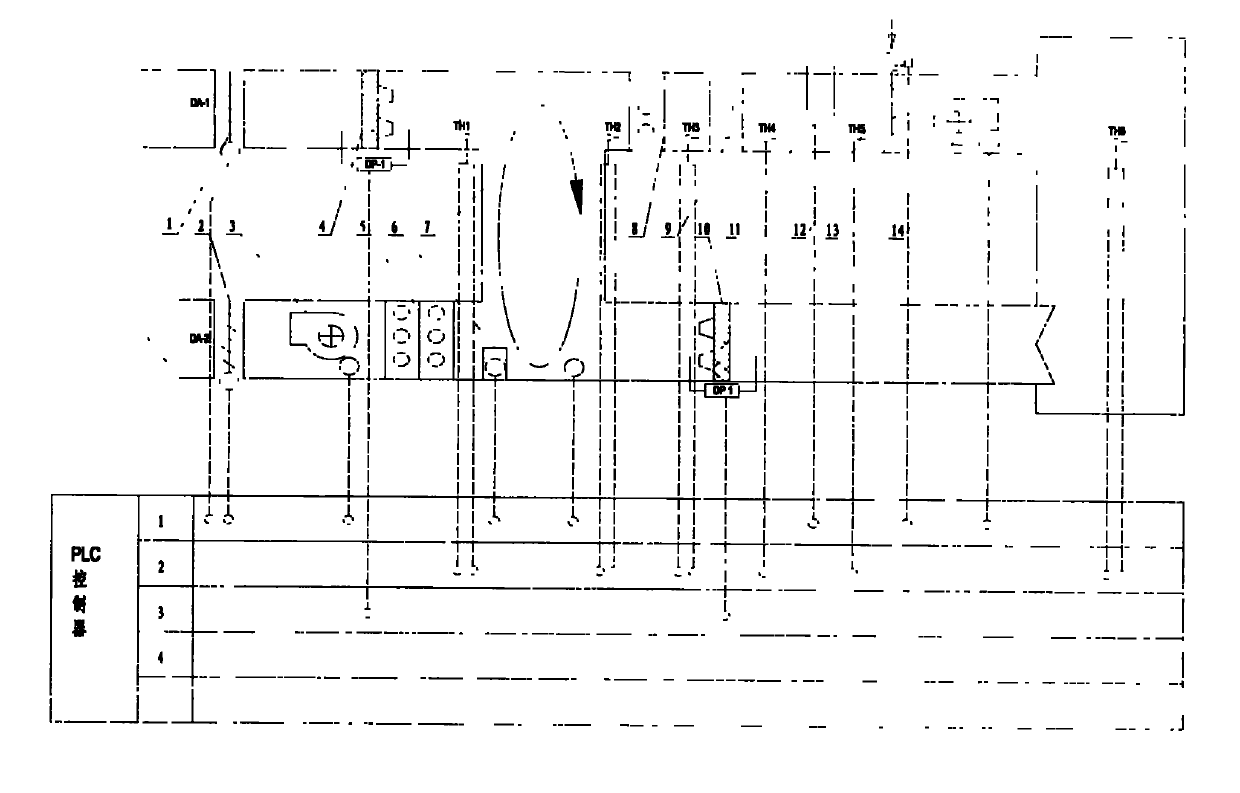

[0022] Refer to attached figure 1 , attached figure 2 and attached image 3 , set forth as follows with regard to implementing an embodiment of the present invention:

[0023] After the fresh air passes through the fresh air executive valve DA-1 (1) and the fresh air filter (4), the temperature T measured by TH1 1 and humidity ψ 1 , sent to the PLC controller, and the set value T of temperature and humidity 设 and ψ 设 Compare to determine whether to open the rotary wheel type full heat type recovery device (7) and the compressor; the fresh air enters the rotary wheel type full heat type recovery device (7), and the return air filtered by the return air filter (10) is in the The energy exchange of sensible heat and latent heat is performed in the rotary wheel type f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com