Multi-connected unit phase change energy storage hot liquid defrosting system

A phase-change energy storage and hydrothermal defrosting technology, which is used in ventilation and heating energy recovery systems, air conditioning systems, ventilation systems, etc. Slow and other problems, to achieve the effect of improving reliability, speeding up defrosting speed, and prolonging life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

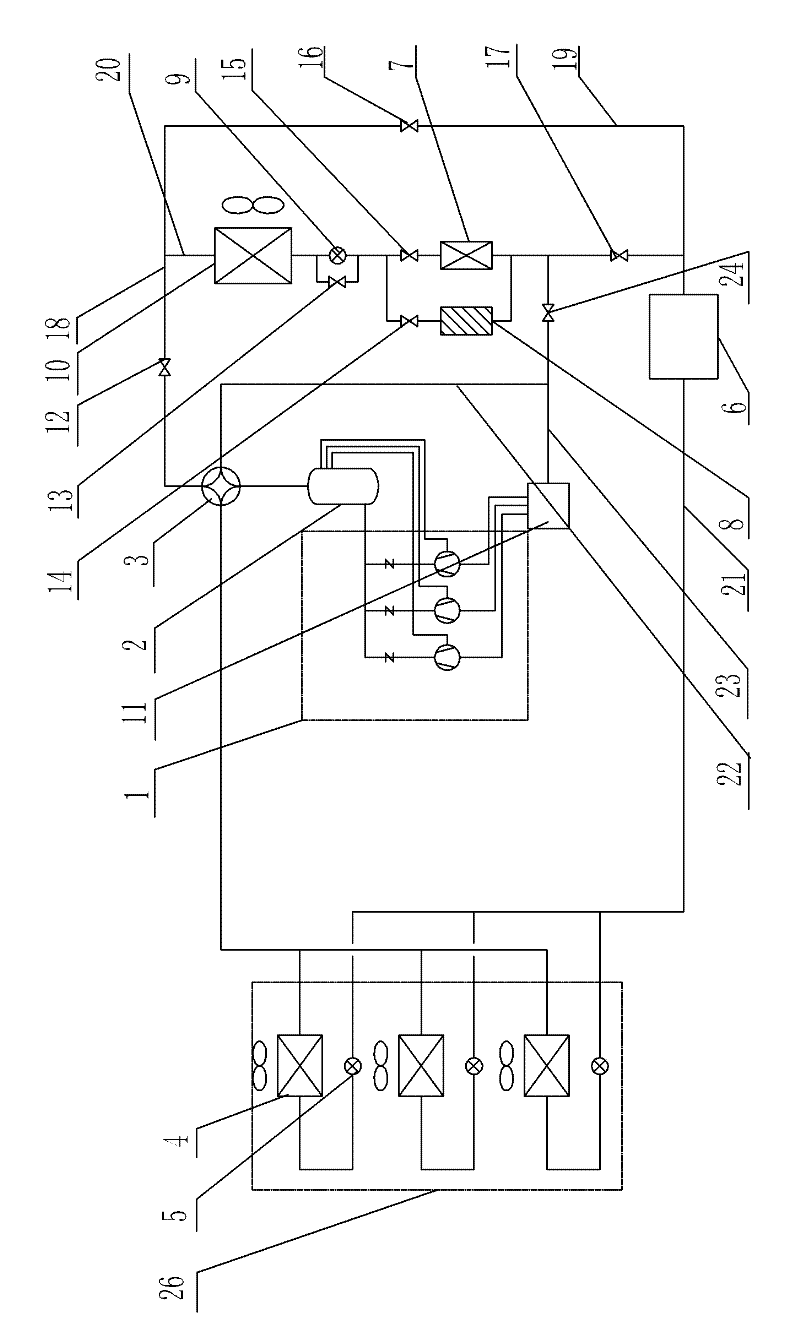

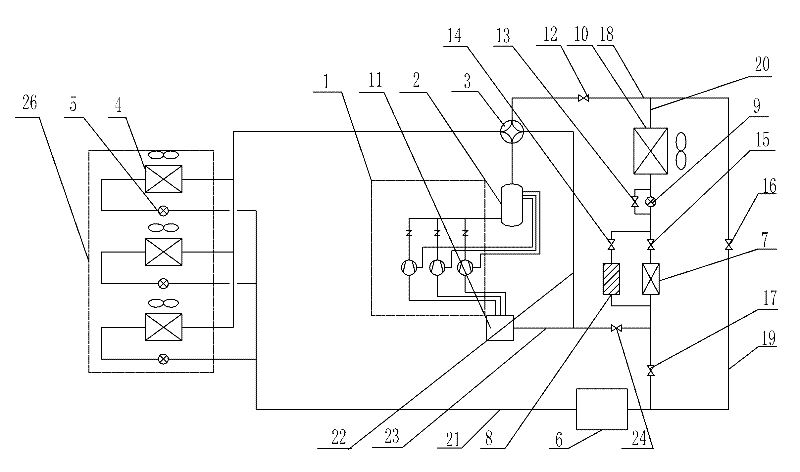

[0009] Specific implementation mode one: combine figure 1 Describe this embodiment. The system of this embodiment includes a compressor unit 1, an oil separator 2, a four-way reversing valve 3, a liquid receiver 6, a subcooler 7, an outdoor electronic expansion valve 9, an outdoor heat exchanger 10, a gas Liquid separator 11 and indoor unit 26, the outlet end of compressor unit 1 communicates with the inlet end of oil separator 2, the outlet end of oil separator 2 communicates with one of the through holes of four-way reversing valve 3, and the system also Including phase change heat accumulator 8, first solenoid valve 12, second solenoid valve 13, third solenoid valve 14, fourth solenoid valve 15, fifth solenoid valve 16, sixth solenoid valve 24, seventh solenoid valve 17, The first main road 18, the first branch pipeline 19, the second branch pipeline 20, the second main road 21, the third main road 22 and the fourth main road 23, and the remaining three through holes of the...

specific Embodiment approach 2

[0014] Specific implementation mode two: combination figure 1 To illustrate this embodiment, the phase change material in the phase change heat accumulator 8 of this embodiment is CaCl 2 ·6H 2 O or Na 2 SHO 4 10H 2 O, because this system requires the temperature range of the phase change material in the phase change heat accumulator 8 to be 20-35 degrees Celsius, the latent heat of phase change per unit volume should not be less than 250KJ / L, and the thermal conductivity should not be less than 0.5W / mK, so the above-mentioned Inorganic phase change material, mixed with a small amount of additives to prevent supercooling and phase separation. to CaCl 2 ·6H 2 O can add BaCO with a mass fraction of about 2% 3 and 2% SrCl 2 ; to Na 2 SHO 4 10H 2 O can add mass fraction about 2% borax 2% superabsorbent resin. Phase-change temperature heat accumulator structure: The heat accumulator should not adopt the spiral tube and casing type structure, because the resistance is lar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com