Semiconductor silicon wafer cleaning process chamber and cleaning method

A semiconductor and process chamber technology, which is applied to the semiconductor silicon wafer cleaning process chamber and the field of cleaning, to achieve the effects of improving the cleaning effect, reducing the liquid consumption and reducing the thickness of the boundary layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to better understand the technical content of the present invention, specific embodiments are given together with the attached drawings for description as follows.

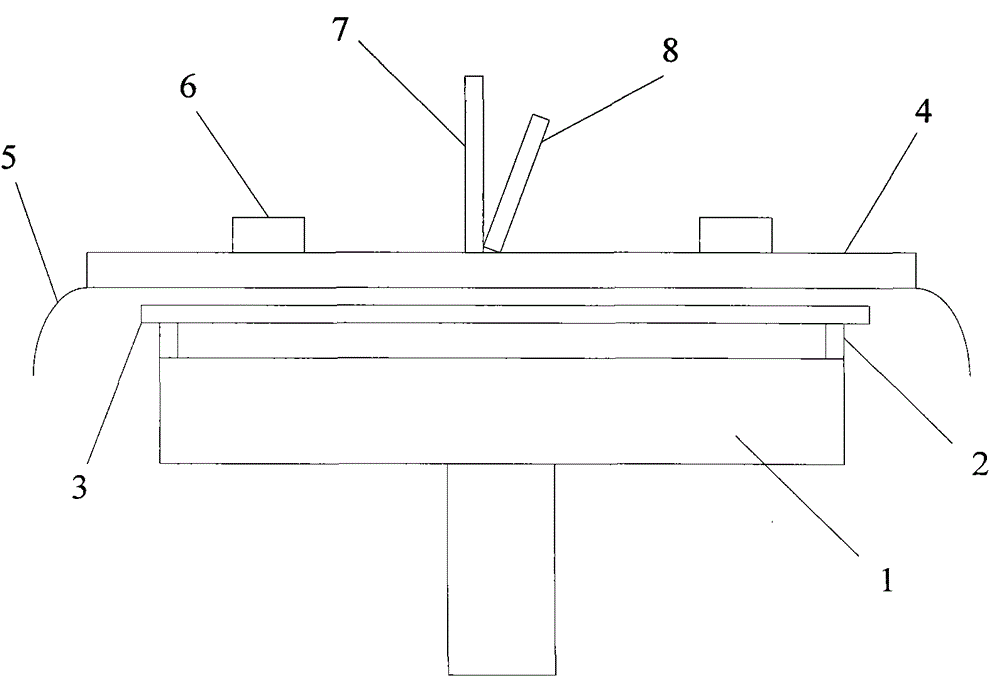

[0024] Please refer to figure 1 , figure 1 Shown is a schematic structural diagram of a cleaning process chamber for semiconductor silicon wafers according to a preferred embodiment of the present invention. The present invention provides a cleaning process chamber for semiconductor silicon wafers. Inside the process chamber, there is a platform 1 that can be lifted and rotated. Above the platform 1, there are several silicon wafer supports 2 with vacuum pipelines for carrying and fixing silicon wafers. Sheet 3, a cover plate 4 with an area larger than the silicon chip 3 is arranged above the silicon chip 3, and the cover plate 4 has one or more water outlet holes 7, which are connected to different liquid or gas pipelines 8 , the cover plate 4 is equipped with an ultrasonic oscillator 6 , the ed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com