Production method of fungal fermentation feed

A fermented feed and production method technology, applied in animal feed, animal feed, botanical equipment and methods, etc., can solve the problems of unclear product functional components, lack of product standards, low technical level, etc. Improve immunity and improve the effect of breeding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

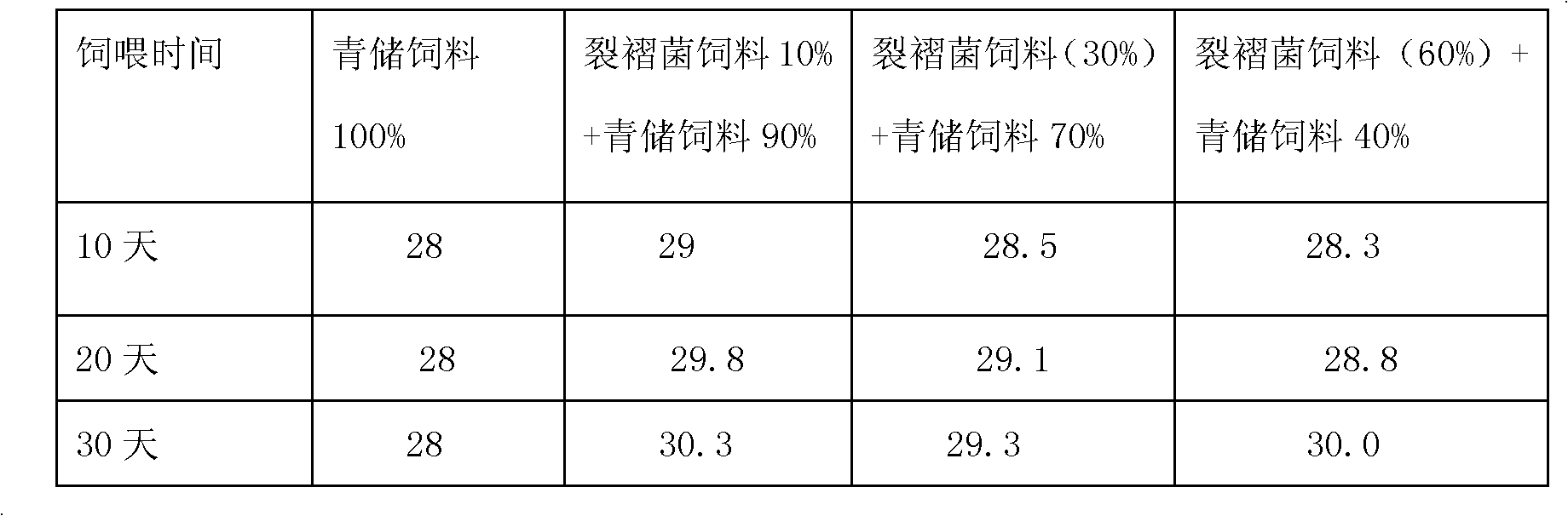

Examples

Embodiment 1

[0033] Embodiment 1 (production method of Schizophyllum feed product)

[0034] A Schizophyllum feed product is mainly composed of crushed Schizophyllum mycelium and dry solids in the Schizophyllum fermentation broth. The product in this example exists in powder form, and the product is composed of Schizophyllum solid fermentation Composed of fungus, the production process of the product of the present invention is as follows: the solid fermentation culture of the schizophyllum, the solid fermentation culture of the schizophyllum is crushed and dried, and the product is packaged.

Embodiment 2

[0036] The production process of Schizophyllum feed is as follows:

[0037] (1) Activation culture of slant strains: Transfer the preserved slants of Schizophyllum slant cultures to the slant medium, and cultivate them at 22°C for about 96 hours until the mycelia cover the slant;

[0038] (2) Liquid first-level seed culture: pick a piece of the above-mentioned Schizophyllum slant strains and insert it into a 500-milliliter shaker flask equipped with 100 milliliters of medium for first-level seed culture, culture conditions: rotary shaker 150 rpm Incubate at 25°C for about 130 hours;

[0039] (3) Liquid secondary seed cultivation: the primary shake flask seed is inserted in the 500 milliliter shake flask that 100 milliliters of culture medium is housed with 5% inoculum to carry out secondary seed cultivation, culture condition: rotary shaker 180 revs / Incubate at 25°C for about 100 hours;

[0040](4) solid fermentation culture: insert the secondary shake flask seeds with 10% ...

Embodiment 3

[0047] The production process of Schizophyllum feed is as follows:

[0048] (1) Activation culture of slant strains: transfer the preserved slants of Schizophyllum slant cultures to the slant medium, and cultivate them at 28°C for about 96 hours until the mycelia cover the slant;

[0049] (2) Liquid first-level seed culture: pick a piece of the above-mentioned Schizophyllum slant strains and insert it into a 500-milliliter shake flask equipped with 100 milliliters of medium for first-level seed culture, culture conditions: rotary shaker 180 rpm Incubate at 28°C for about 96 hours;

[0050] (3) Liquid secondary seed cultivation: the primary shake flask seed is inserted in the 500 milliliter shake flask that 100 milliliters of culture medium is housed with 5% inoculum to carry out secondary seed cultivation, culture condition: rotary shaker 180 revs / Incubate at 28°C for about 96 hours;

[0051] (4) solid fermentation culture: the second-stage shaker flask seeds are inserted i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com