Method for preparing carbon fiber brake lining

A friction lining and carbon fiber technology, applied in the field of materials, can solve the problems of unreasonable material ratio and poor interface bonding force of carbon fiber, and achieve the effect of excellent braking stability, strong environmental resistance and low density.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

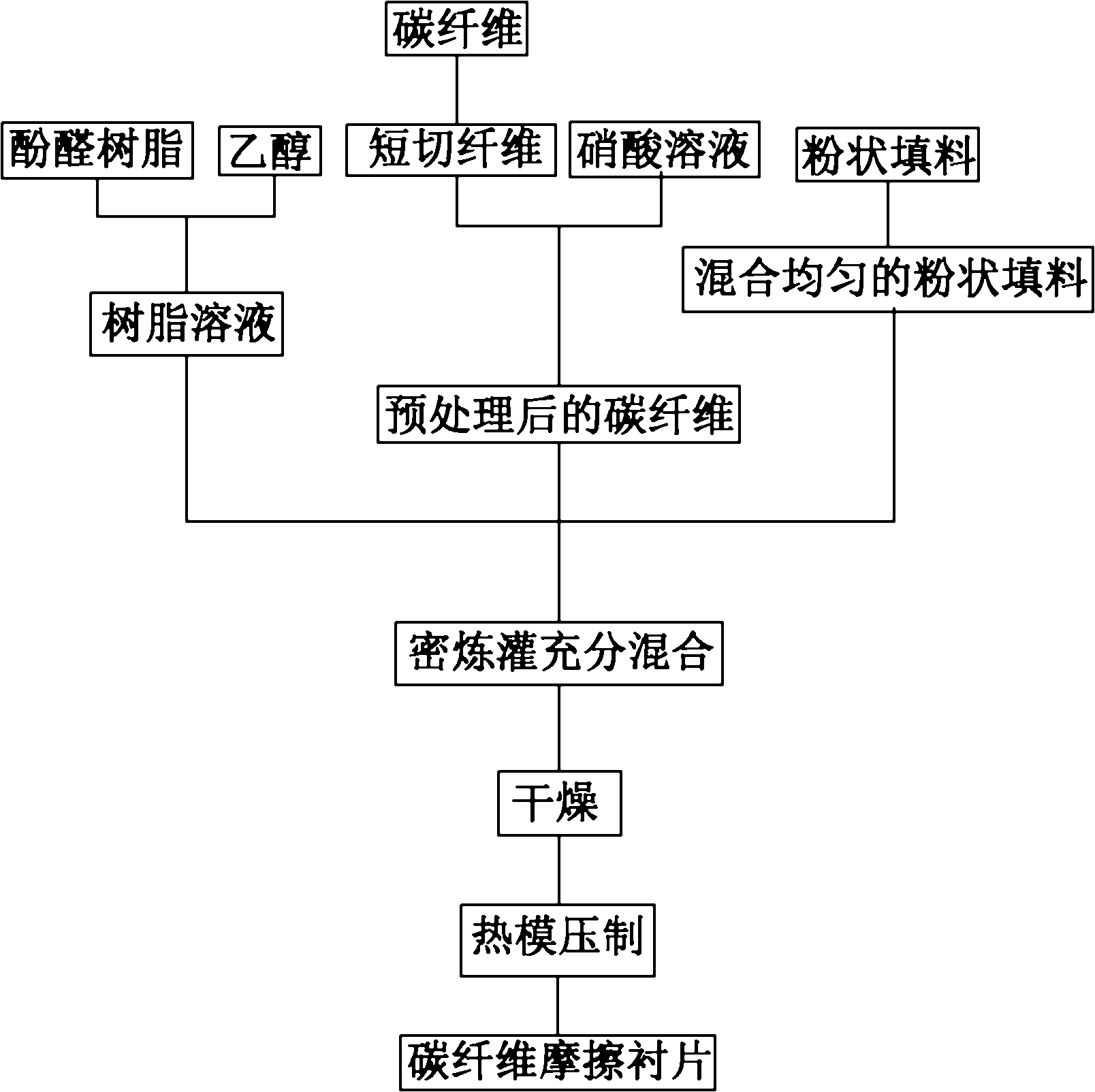

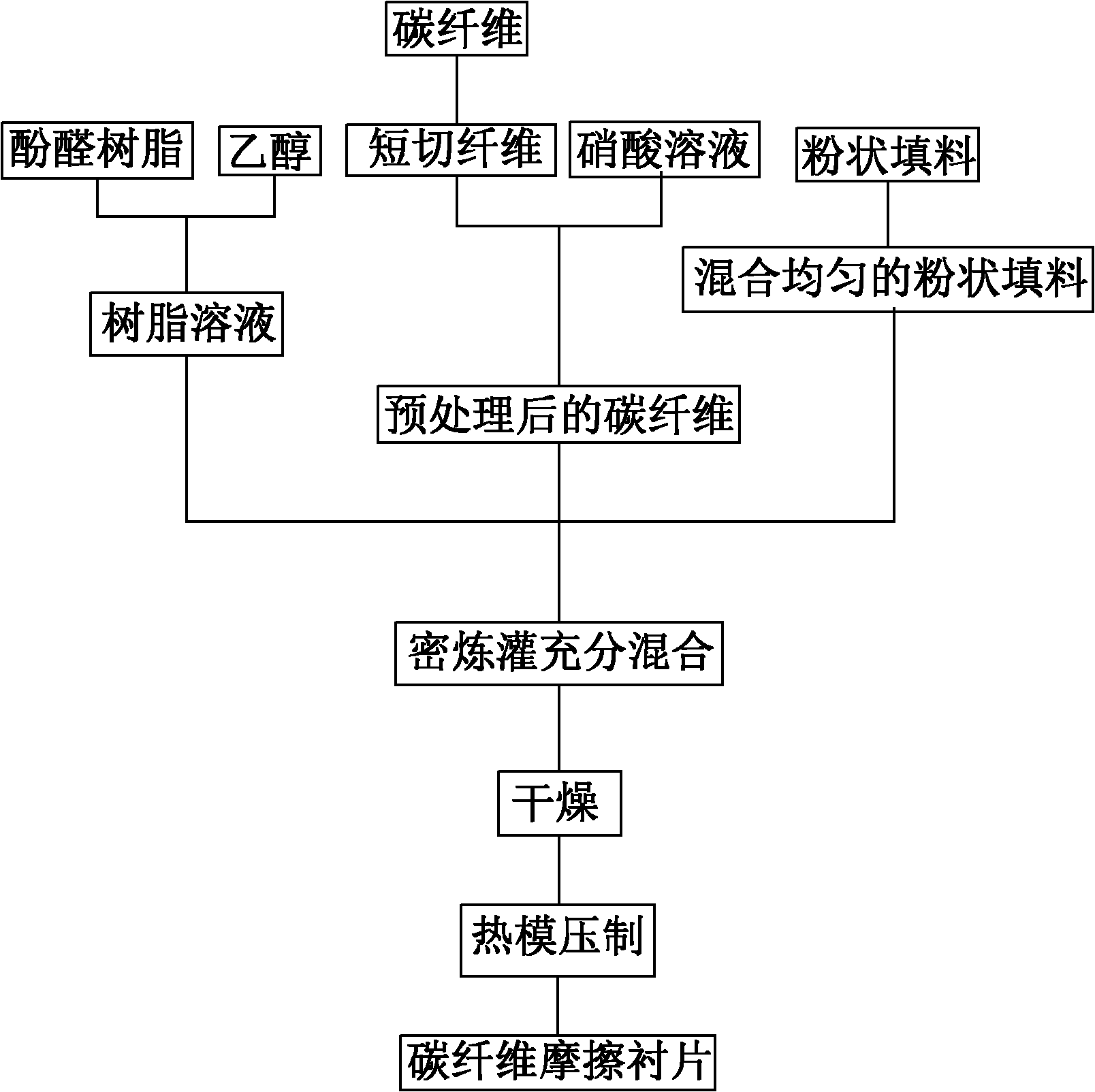

[0020] like figure 1 Shown, the preparation method of this brake carbon fiber friction lining comprises the following steps:

[0021] A. Carbon fiber pretreatment: put carbon fiber in nitric acid solution, heat for a period of time, take it out and dry it for later use. The carbon fiber is a chopped fiber of 1-5mm or cut from a carbon fiber tow into a chopped fiber with a length of 1-5mm, and the carbon fiber is a PAN-based carbon fiber. The concentration of nitric acid solution is 60-70%. Treat at a temperature of 75-85°C for 6-10 hours.

[0022] B. Preparation of resin solution: mix phenolic resin and ethanol to prepare a resin solution for later use. The ethanol is absolute ethanol, and the weight ratio of the absolute ethanol to the phenolic resin is 1:3 to 1:12.5.

[0023] C. Mix powdery filler: Mix the powdery filler containing copper powder, alumina powder, kaolin powder and talcum powder evenly. Other materials can also be added to the powdered filler as needed, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com