Pressure-resistance and adjustment test bed for aircraft hydraulic system

A technology of adjustment test and aircraft hydraulics, which is applied in the field of testing, can solve the problems of oil return pressure interference of two sets of functional units, poor safety, and short life of the compression test bench, so as to avoid long-term work or frequent start-up, and prevent stalling Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

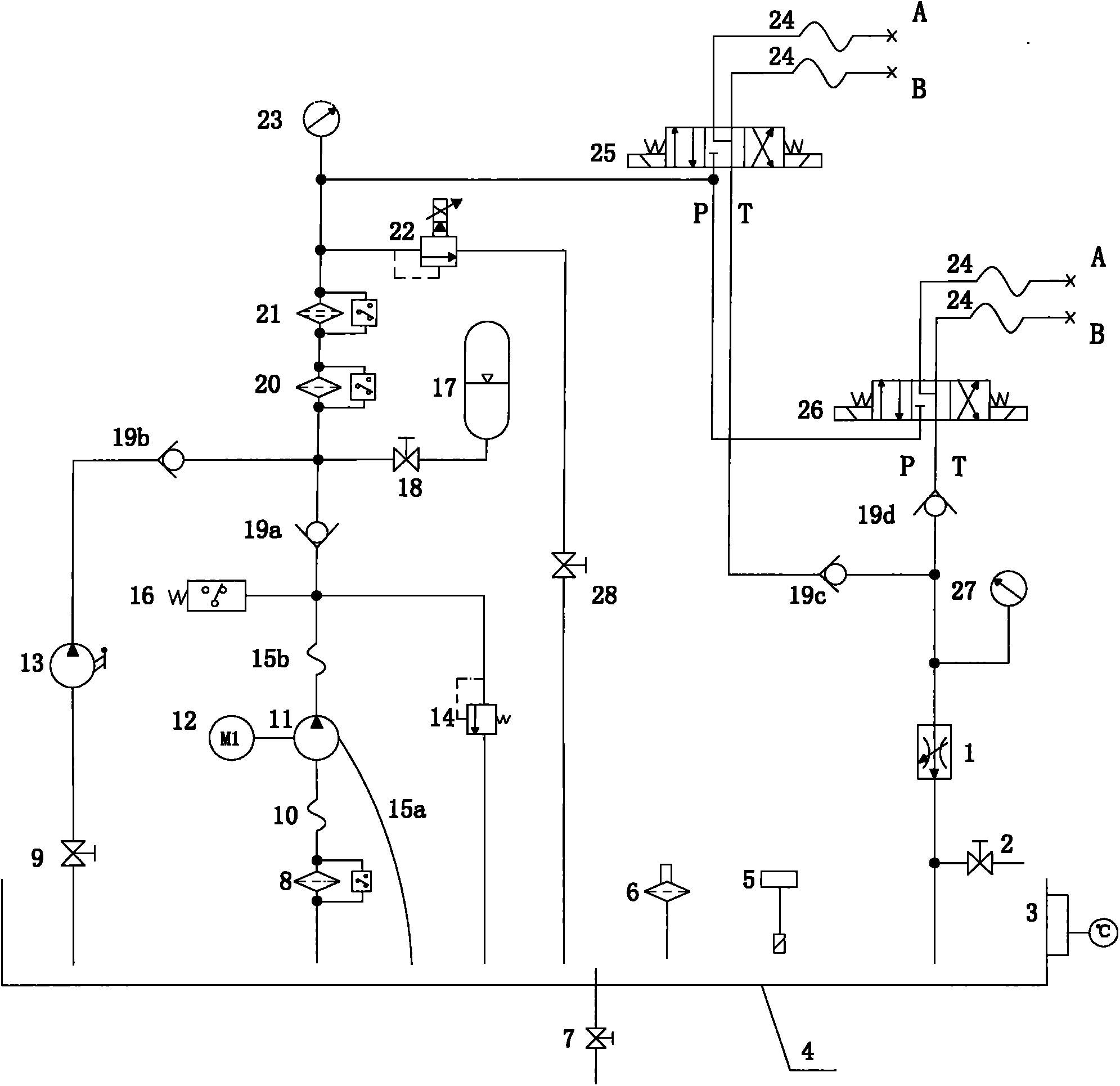

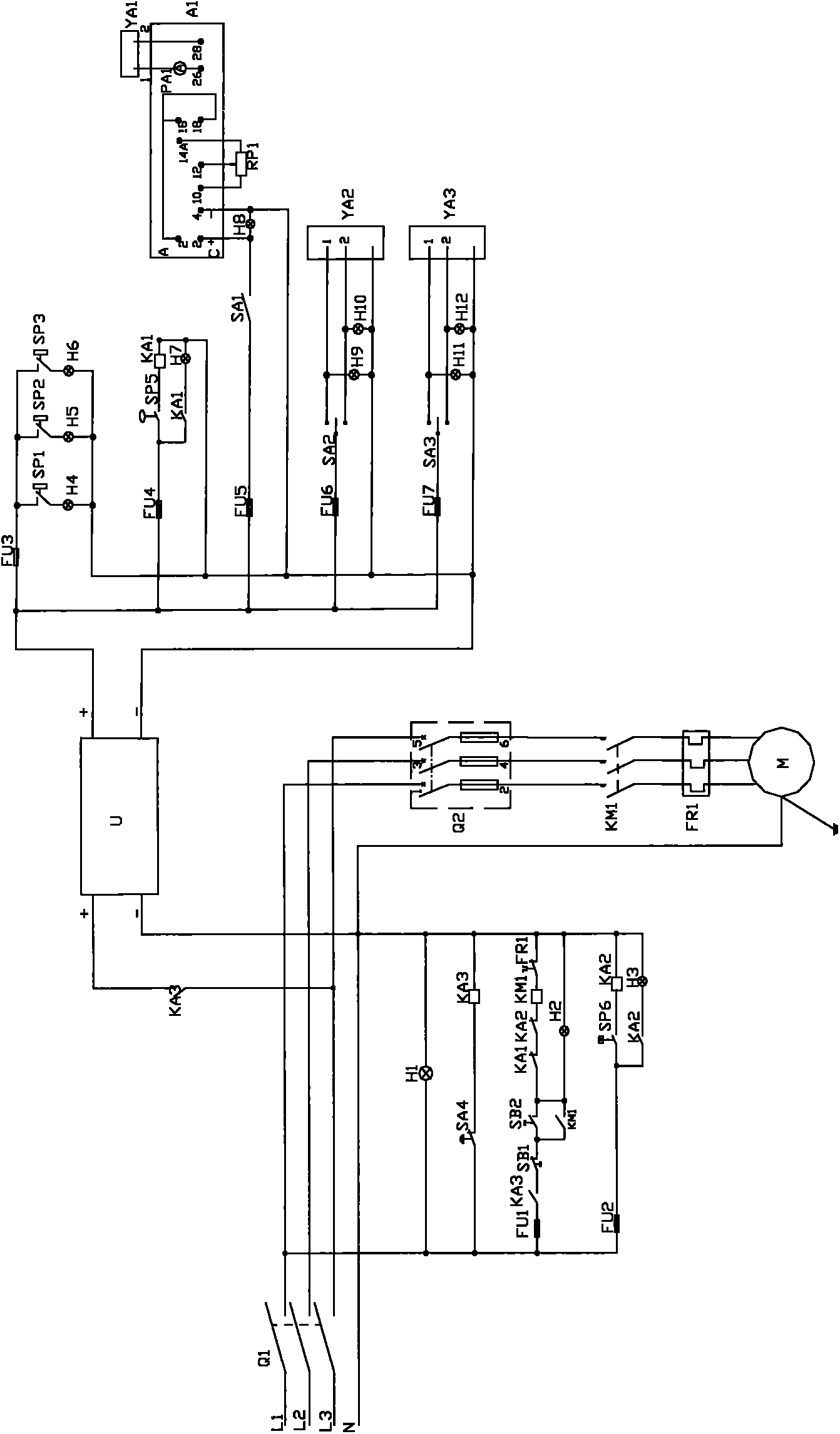

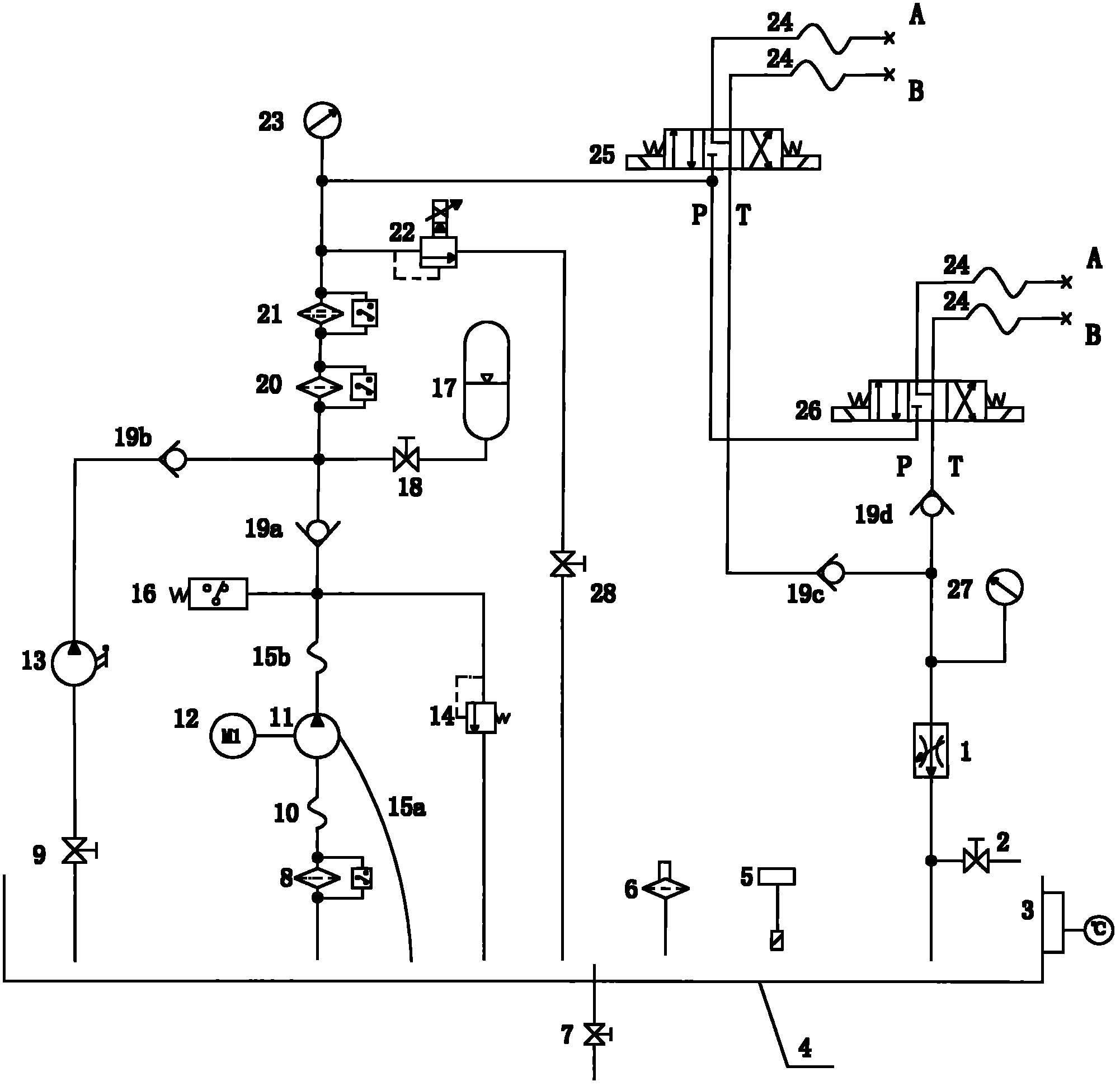

[0016] Combine below figure 1 , figure 2 The present invention is described in further detail with the specific embodiment:

[0017] The test bench includes hydraulic part and electrical part,

[0018] (1) Hydraulic part

[0019] A liquid level thermometer 3, a liquid level relay 5, an air filter 6, an oil discharge valve 7, and an oil suction filter 8 are installed on the oil tank 4, and the oil suction filter 8 is connected to the hydraulic pump 11 through the oil suction hose 10, and the hydraulic pump The oil drain port of 11 is connected with the oil drain hose 15a, and the oil outlet port of the hydraulic pump 11 is connected with the overflow valve 14, the pressure relay 16 and the first one-way valve 19a through the high-pressure hose 15b, and the first one-way valve The outlet end of 19a is connected with the communication valve 18, the accumulator 17 and the primary pressure filter 20, the primary pressure filter 20 passes through the secondary pressure filter 21...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com