LED (light emitting diode) lighting module

A LED lighting and superconducting technology, applied in energy-saving lighting, lighting devices, fixed lighting devices, etc., can solve the problems of slow heat dissipation of substrate temperature, complex heat dissipation links, small light angle, etc., to prolong working life, improve luminous efficiency, Effect of reducing operating temperature rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

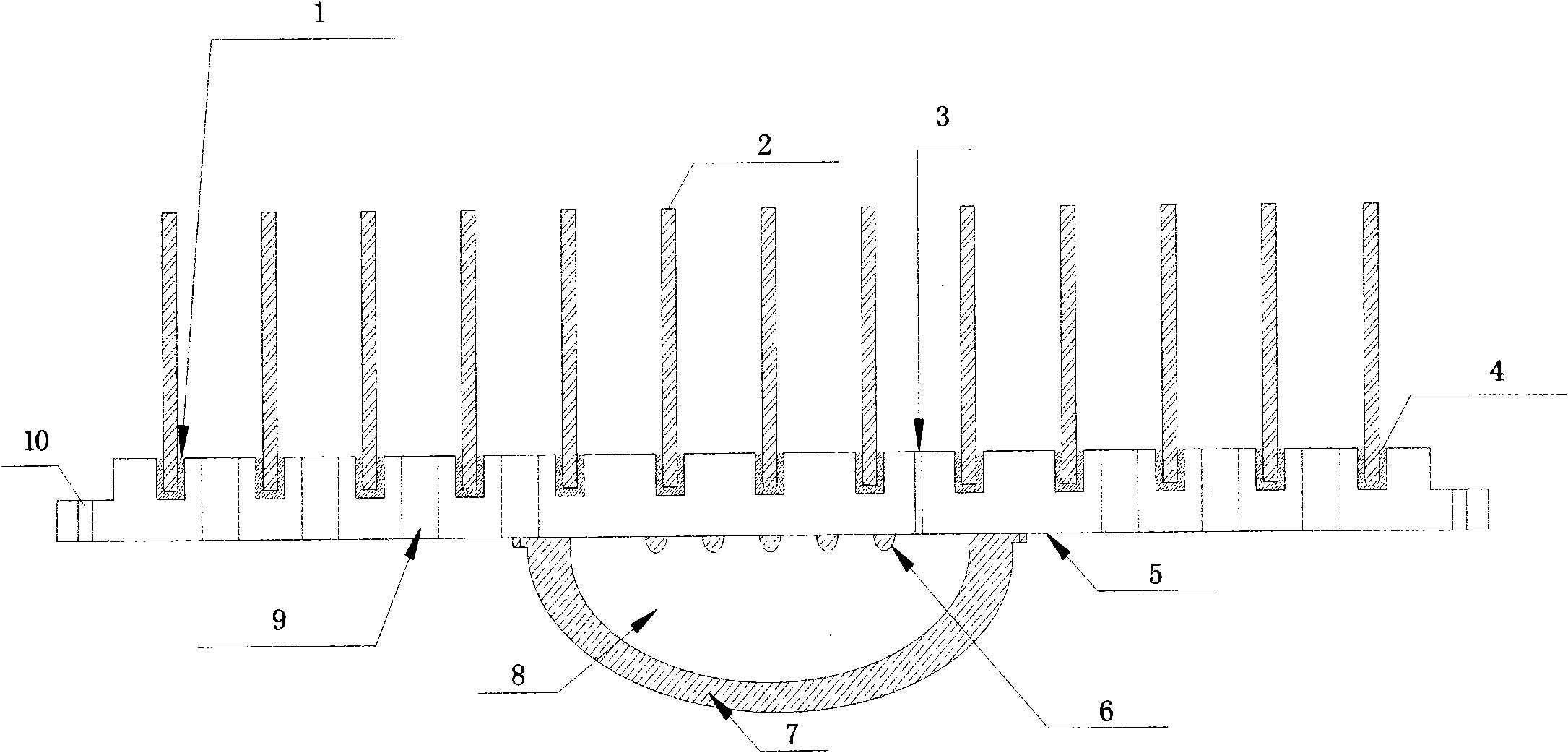

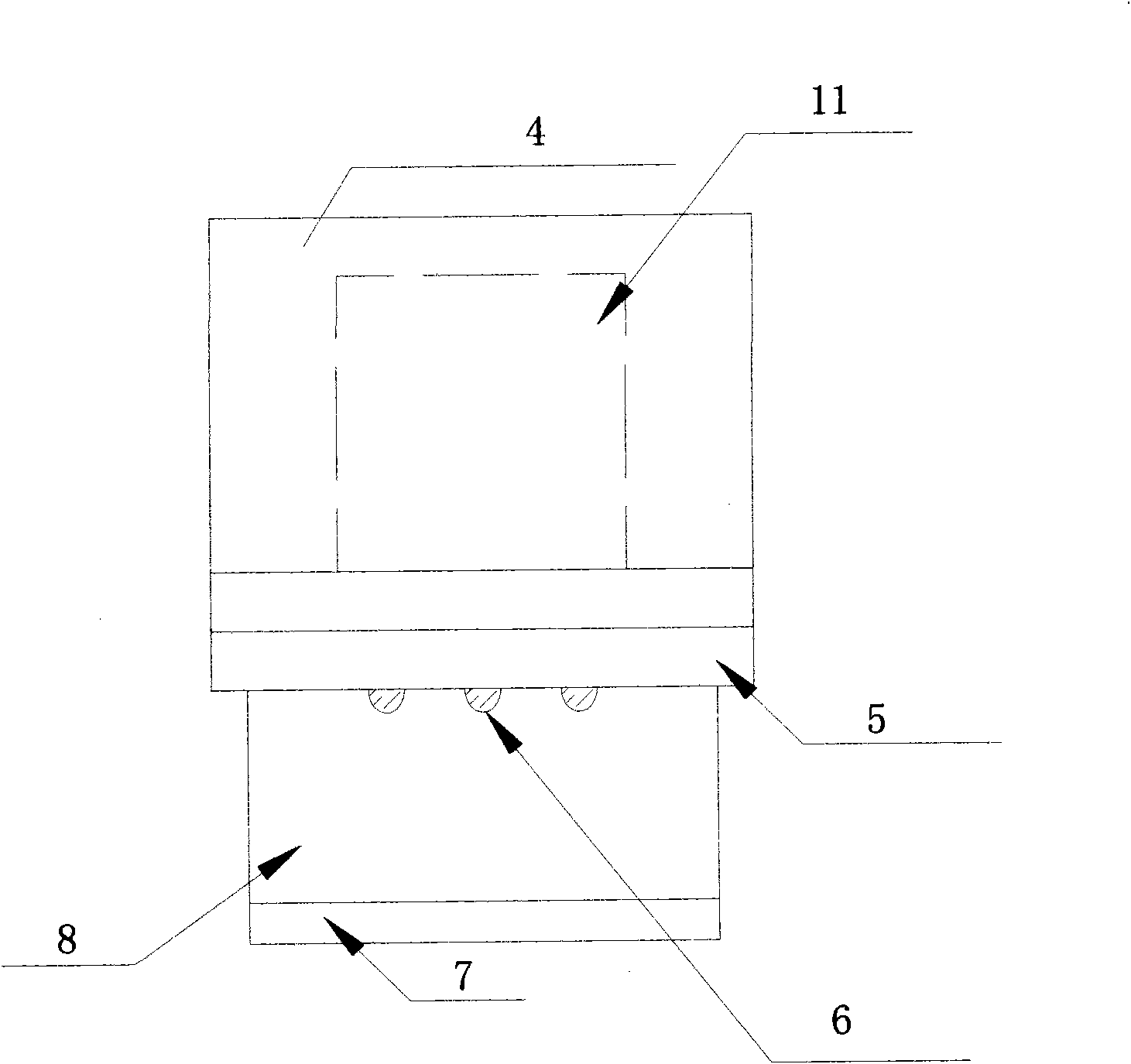

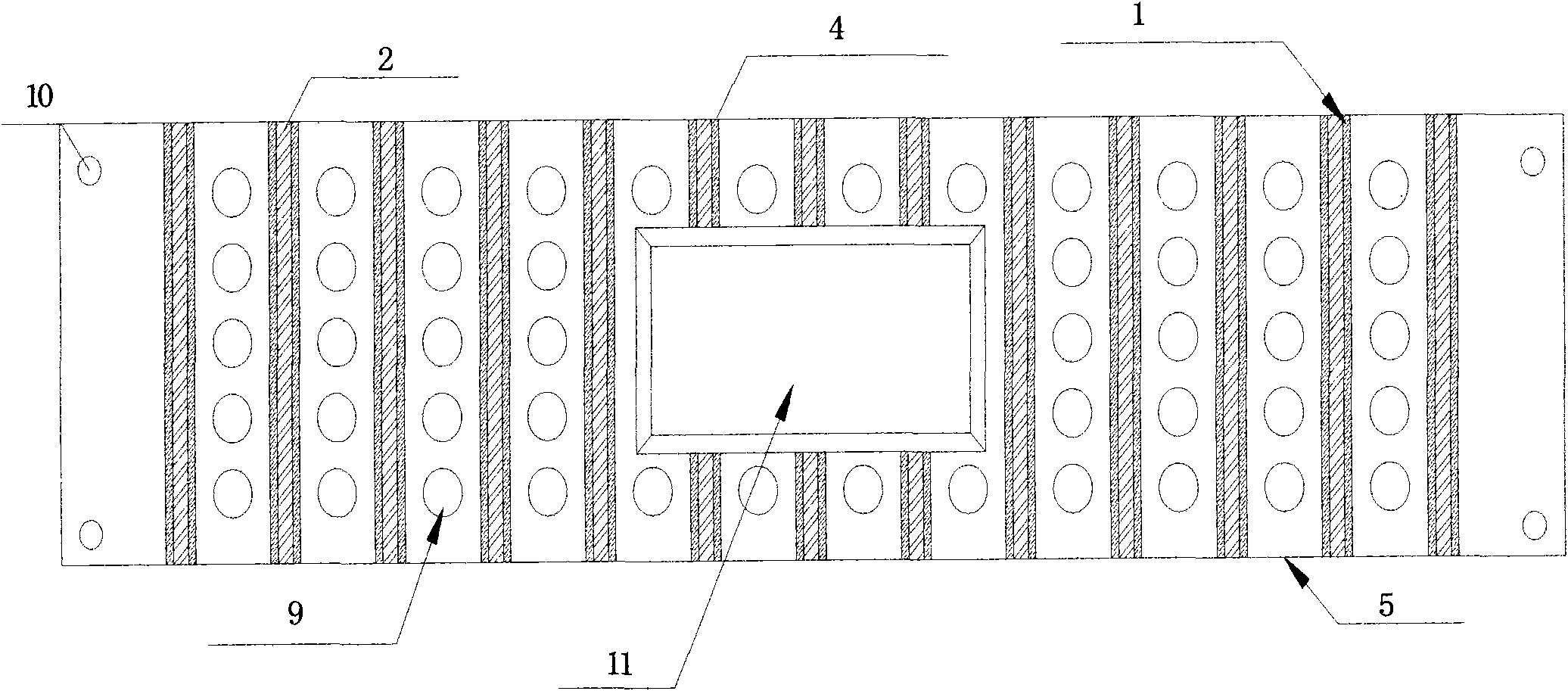

[0022] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0023] The LED lighting module includes a ceramic heat sink, a power supply box, a superconducting base and a light source room. The LED lighting module is provided with a plurality of connecting grooves for ceramic heat sinks on the superconducting base with a plurality of upper and lower transparent heat dissipation holes, and the superconducting base of the ceramic heat sink cavity is formed as a whole through an epoxy resin heat conducting layer, At the same time, a power supply box for installing a driving power supply is provided on the superconducting base; a plurality of LED chips are arrayed at the bottom of the superconducting base, and the LED chips are covered by a light distribution lens to form a light source chamber. The inventive light source room and power supply box of the invention are in a separated state, and the heat si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com