Piezoelectric type torsional wave transducer and piezoelectric transduction type magnetostrictive sensor

A torsional wave and transducer technology, applied in the field of sensors, can solve the problems of complex process, low sensitivity, and high manufacturing cost of torsional wave transducers, and achieve the effects of simple structure, improved sensitivity, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

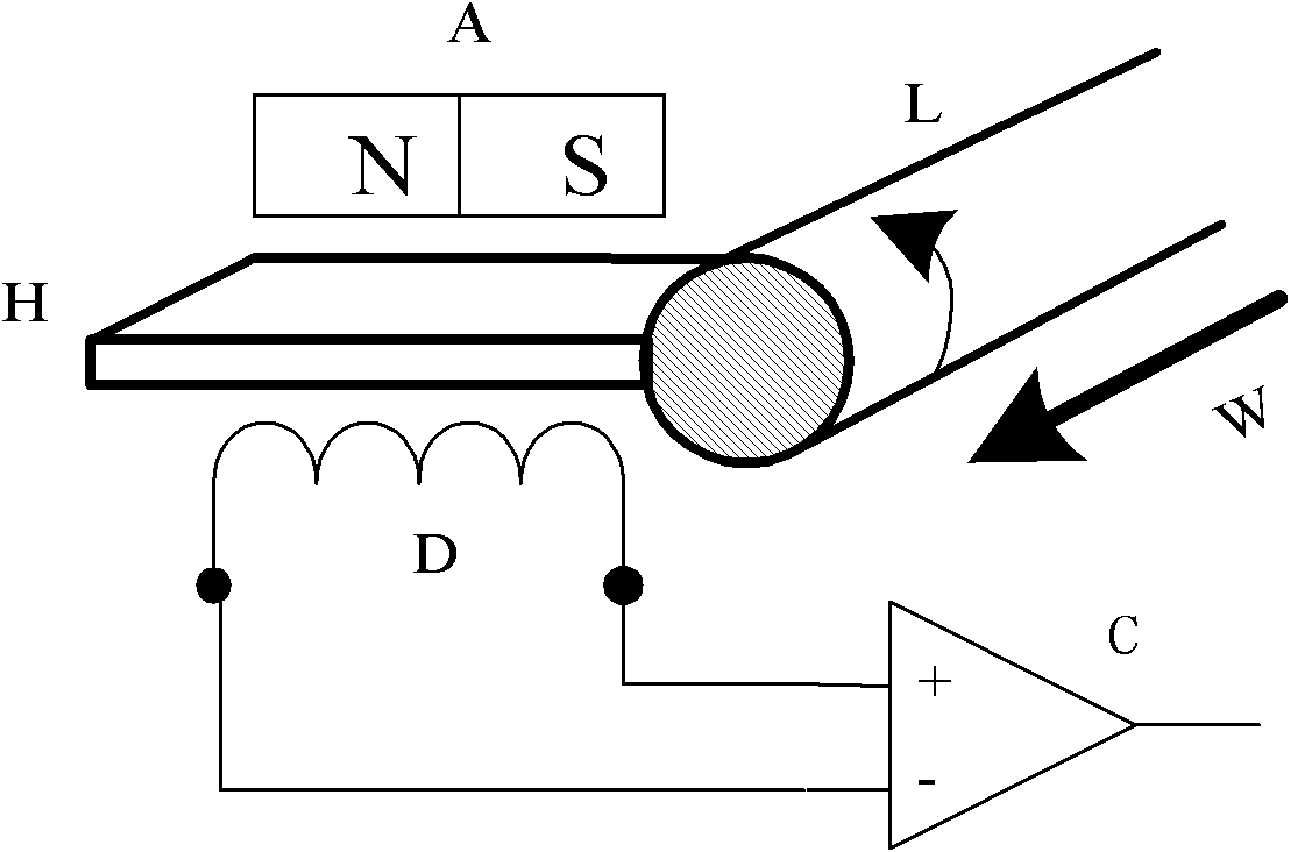

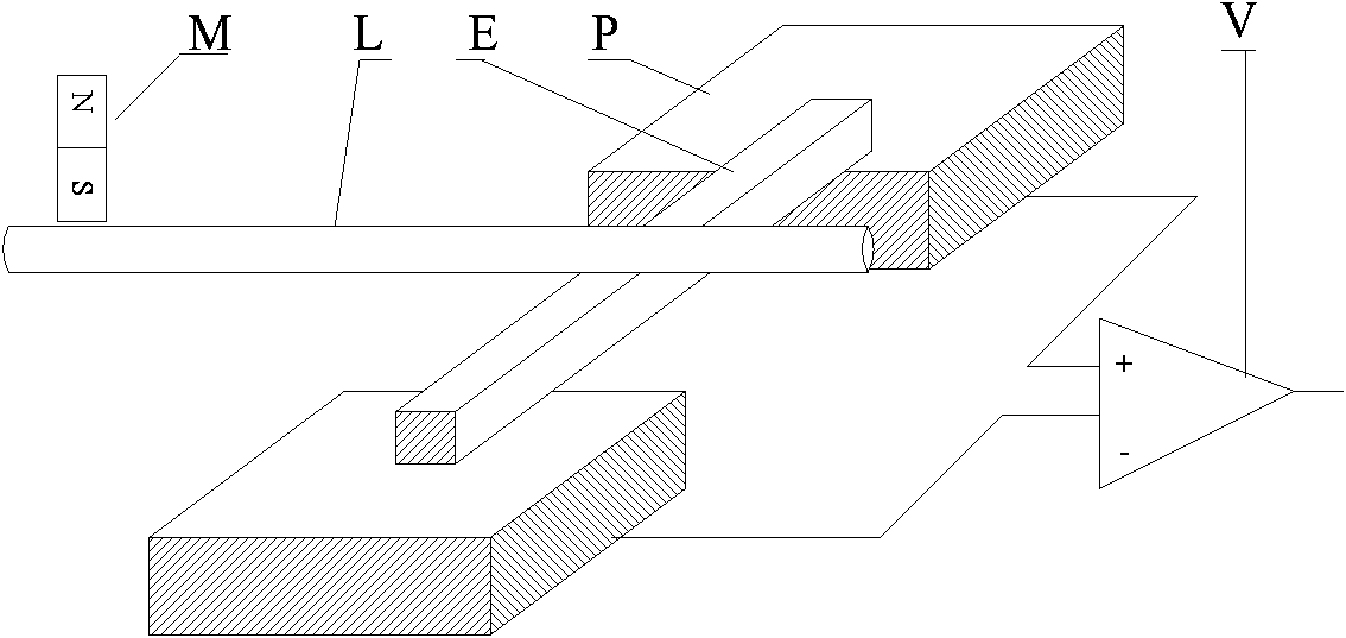

[0029] The structural principle of the present invention and the embodiment applied to liquid level measurement will be further described below in conjunction with the accompanying drawings.

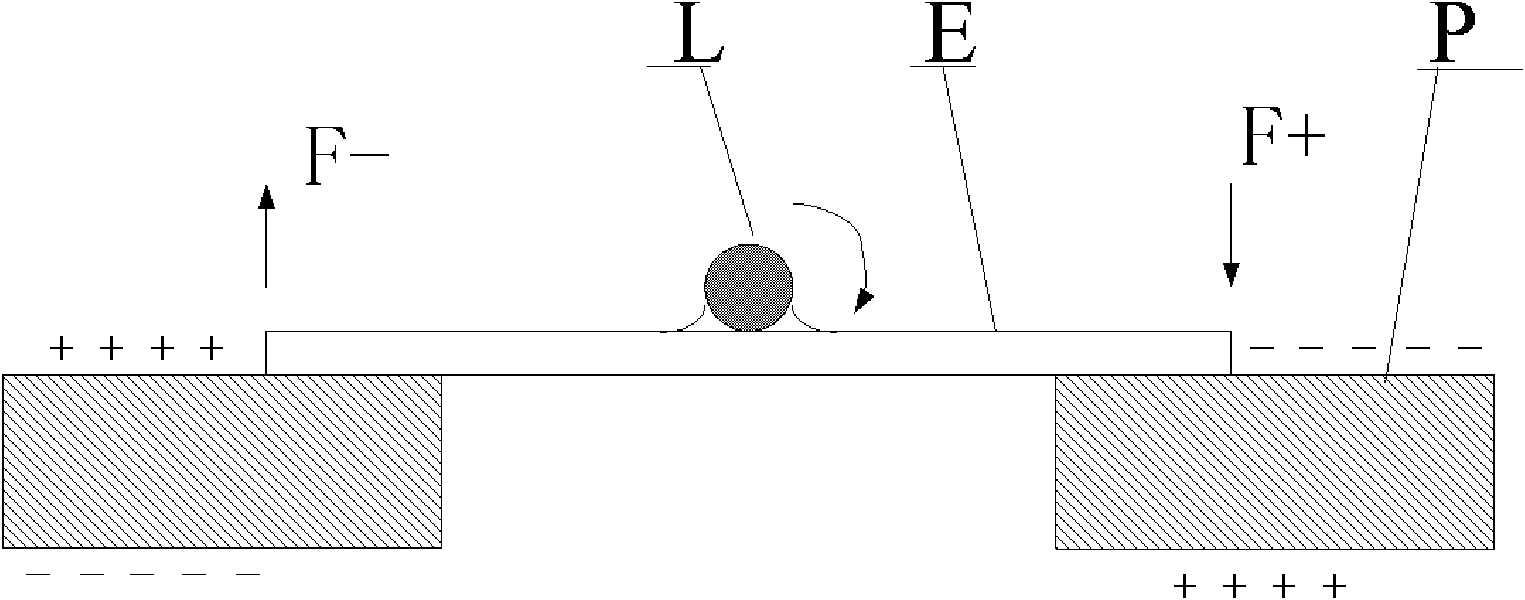

[0030] The structure principle of the piezoelectric torsional wave transducer is as follows: figure 2 , image 3 shown. In the figure, the output section of the waveguide wire L is spot-welded on the side of the waveguide wire 1 with the amplification rod E perpendicular to the waveguide wire L. The piezoelectric elements P connected to the two ends of the amplifying rod E with the same polarity direction are thickness direction sensitive piezoelectric ceramic sheets. The normal line of the plane where the piezoelectric ceramic sheet is located is perpendicular to the waveguide wire L and the amplifier rod E.

[0031] The circumferential torsional wave W signal transmitted by the waveguide wire L is amplified by the amplifying rod E after the torsional deformation of the circumferent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com