N2O micro thruster experiment device

An experimental device, a technology of micro-thrust, which is applied to measuring devices, instruments, force/torque/work measuring instruments, etc., can solve the problem that the thrust and specific impulse performance cannot be effectively improved, the disassembly and loading of catalysts are inconvenient, and the micro-thrust To solve the problem of large size of the device, the installation structure is simple and reliable, the weight is light, and the replacement and disassembly are convenient.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail with reference to the accompanying drawings and embodiments.

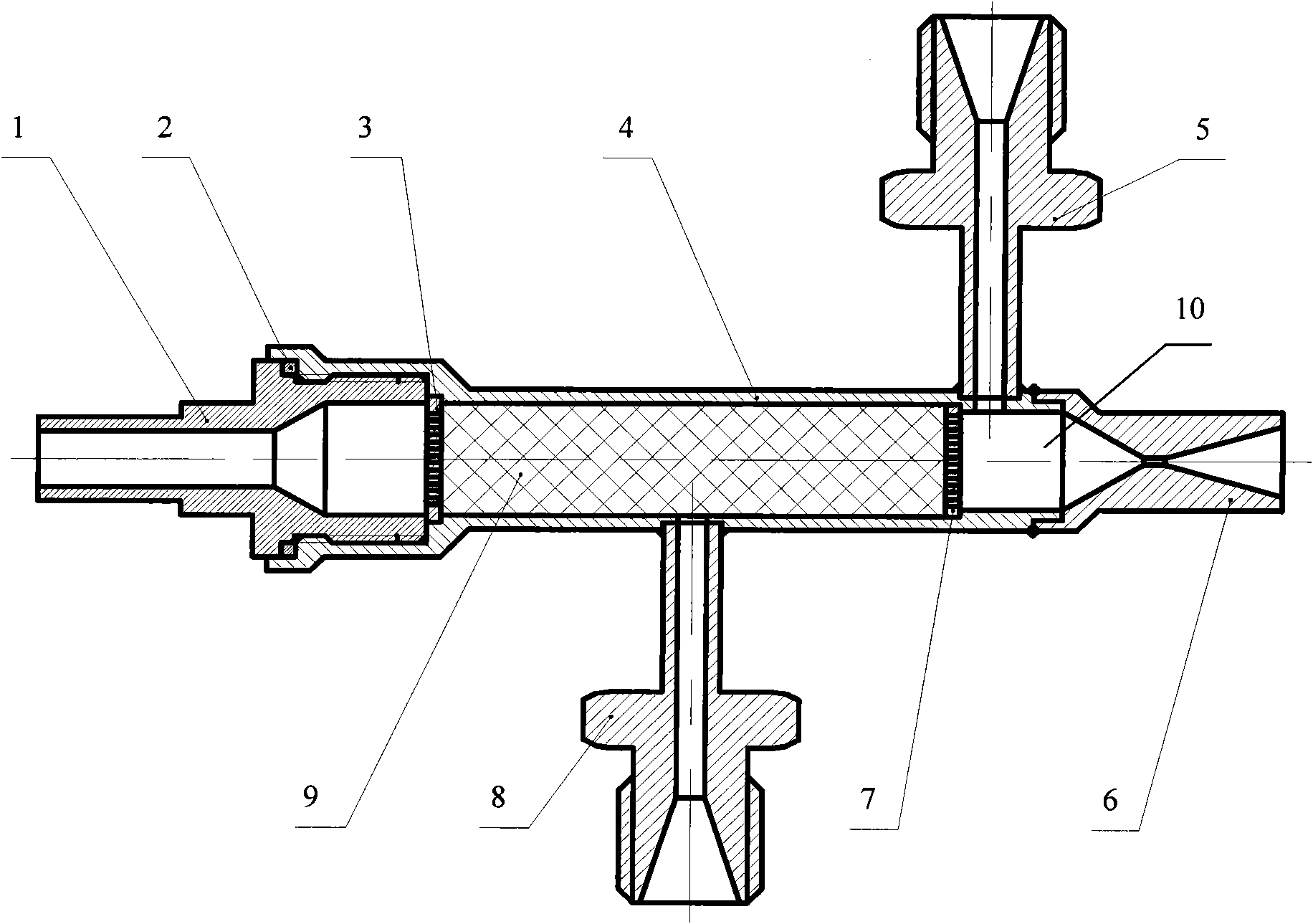

[0025] The present invention is a kind of N 2 O micro thruster experimental device, such as figure 1 shown, including N 2 O intake nozzle 1, copper sealing ring 2, front porous plate 3, catalytic decomposition chamber 4, pressure measuring nozzle 5, micro nozzle 6, rear porous plate 7, temperature measuring nozzle 8 and catalyst particles 9.

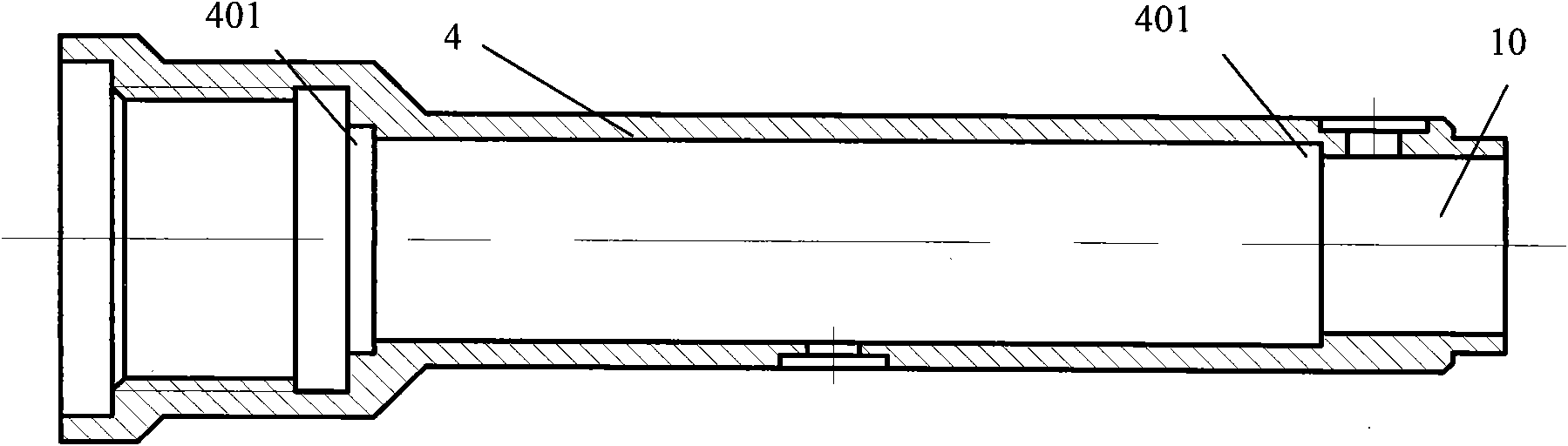

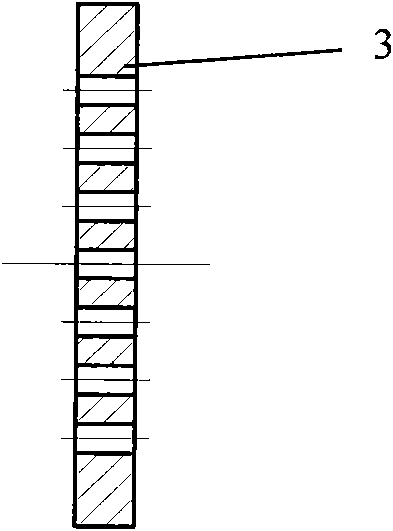

[0026] Such as figure 2 As shown, the two ends of the catalytic decomposition chamber 4 are provided with stepped surfaces 401, the middle of which is filled with catalyst particles 9, and the front porous plate 3 and the rear porous plate 7 are respectively as shown in FIG. image 3 , Figure 4 As shown, a number of through holes with a checkerboard arrangement diameter less than or equal to Φ0.5mm are set in the middle. The more the better in the range, the front porous plate 3 and the rear porous plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com