Thermoplastic resin composition, and molded article

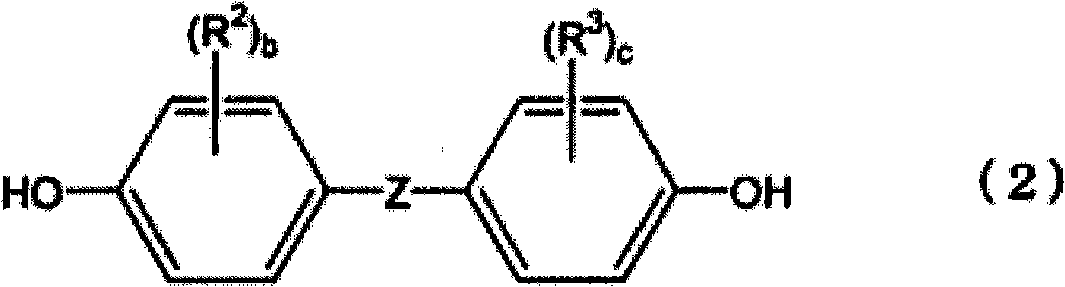

A technology of thermoplastic resin and composition, which is applied in the field of thermoplastic resin composition and its molded body, can solve the problems of long-term heat resistance of deformation and decrease of heat resistance of resin composition, and achieve improved flame retardancy and impact resistance, Excellent chemical resistance and heat resistance, good appearance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~15 and comparative example 1~13

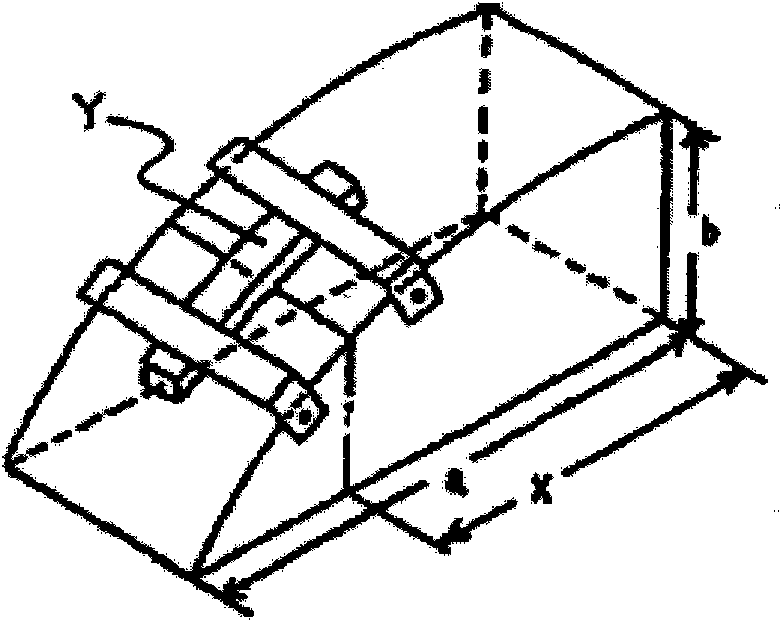

[0146] After drying the components (A) to (E), each component was uniformly mixed in the ratios shown in Table 1 and Table 2 using a rotary drum, and then supplied to a ventilated twin-screw extrusion molding machine with a diameter of 35 mm ( Toshiba Machine Co., Ltd., model name: TEM35), kneaded at a temperature of 260° C., and granulated.

[0147]After drying the obtained pellets at 120° C. for 5 hours, injection molding was performed using an injection molding machine at a cylinder temperature of 240° C. and a metal mold of 80° C. to obtain test pieces.

[0148] The physical properties of the obtained test pieces were measured and evaluated according to the following methods, and the results are shown in Table 1 and Table 2.

[0149]

[0150] (1) Flame retardancy

[0151] A vertical burning test was performed on test pieces having a thickness of 1.2 mm and 1.5 mm produced in accordance with UL Standard 94. According to the test results, the grades of UL-94 flammability...

Embodiment 1~15

[0166] According to the present invention, it is possible to provide a thermoplastic resin composition having improved flame retardancy and impact resistance, and a good balance between chemical resistance and heat resistance. Furthermore, by using the thermoplastic resin composition of this invention, the molded object with few appearance defects can also be provided.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com