Full-automatic device for removing red date pits

A kind of nuclear device, fully automatic technology, applied in the direction of fruit pitting device, food science, application, etc., can solve the problems of low degree of automation, low production efficiency, large pulp loss, etc., achieve high degree of automation, facilitate processing and manufacturing, reduce The effect of labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

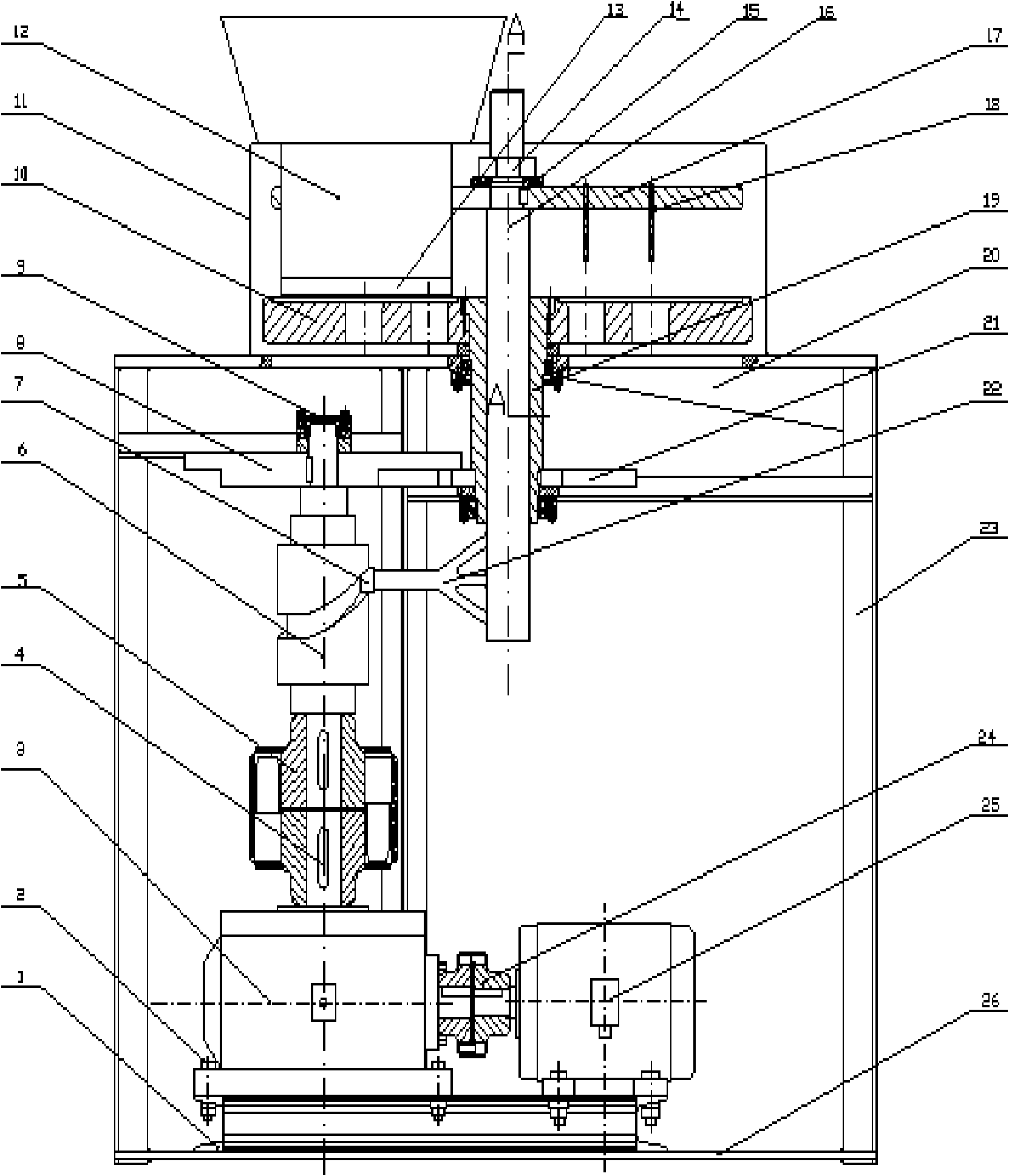

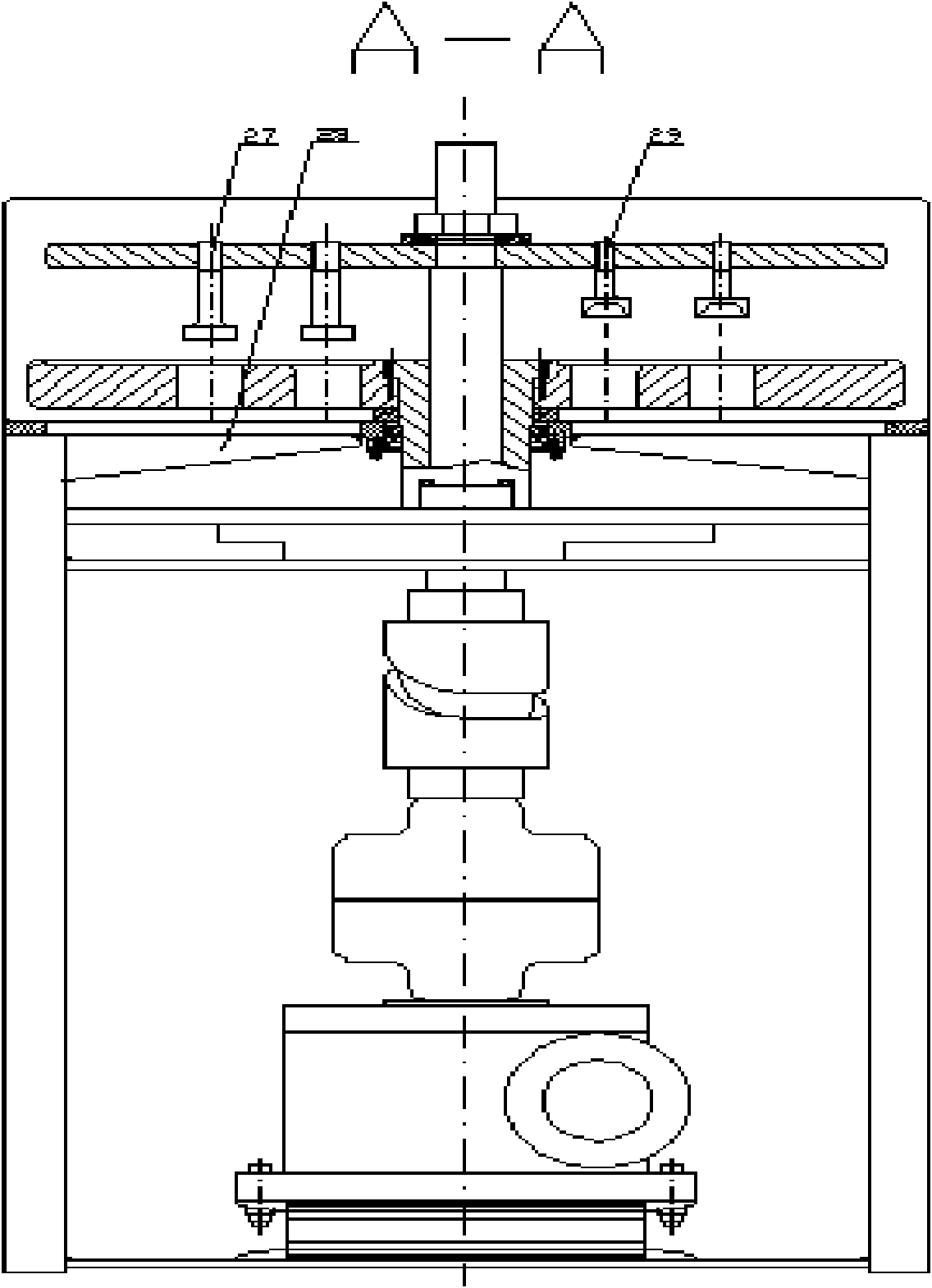

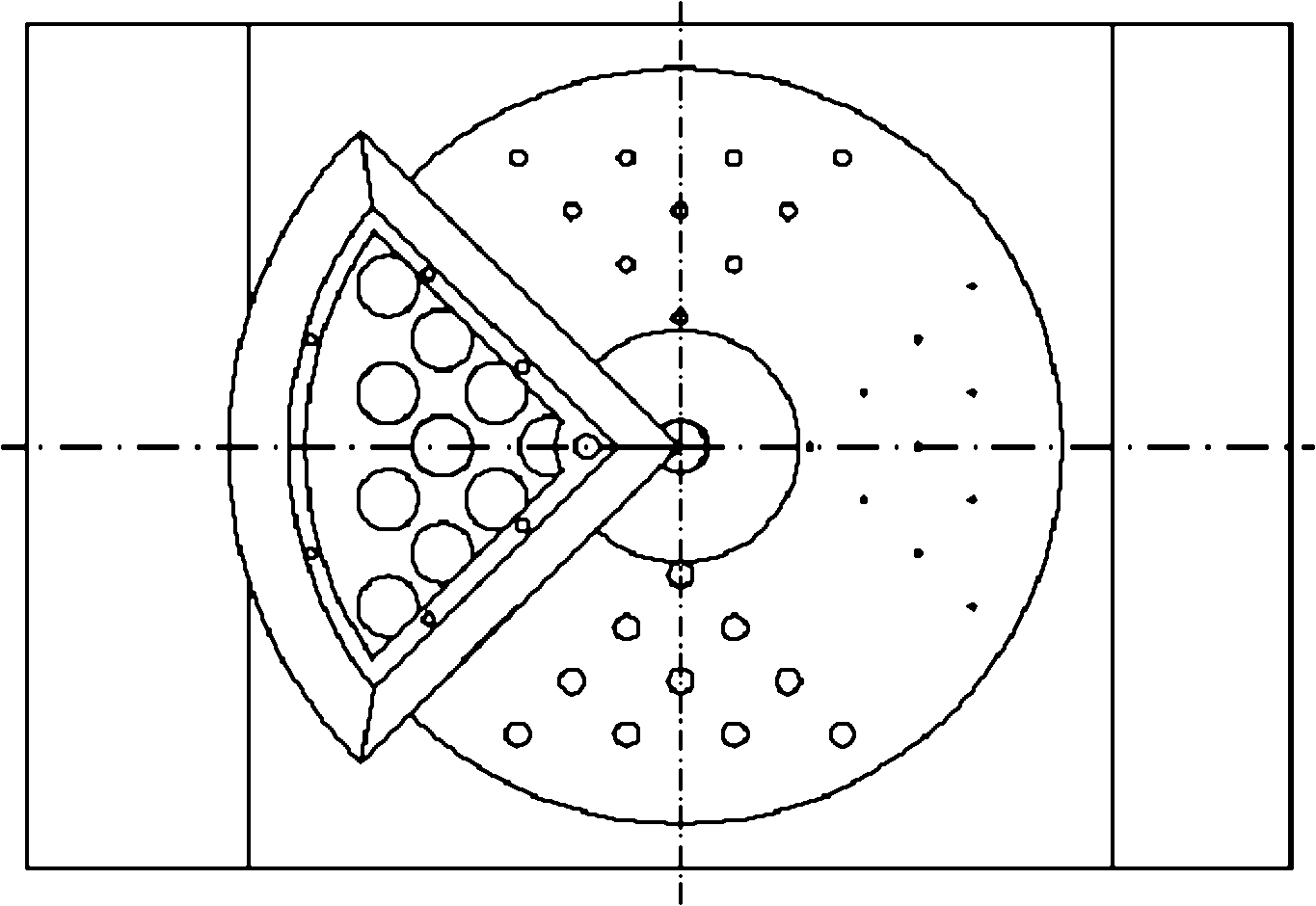

[0022] Below in conjunction with accompanying drawing, full-automatic jujube pitting device of the present invention is described in detail:

[0023] see figure 1 Shown, the full-automatic red date pitting device of the present invention comprises frame 23, the motor 25 that is fixed on the frame 23, the transmission mechanism that is driven by motor 25, and the processing mechanism that is used to process red date.

[0024] The transmission mechanism includes a reduction box 2, a cylindrical cam 6 connected with the reduction box 2 through an elastic coupling 5, and a sheave mechanism fixedly connected with the cylindrical cam 6 through a key and a boss. The reduction box 2 and the motor 25 are fixed on the channel steel 1 by the bolt 2, and the channel steel 1 and the frame 23 are fixed on the angle steel 26 by welding; the reduction box 2 and the elastic coupling 5 are connected by the key 4.

[0025] The sheave mechanism is a single-arm external sheave mechanism, which co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com