Production process of disposable blood lancet and device thereof

A production process and lancet technology, applied in the field of disposable lancet production process and its equipment, can solve the problems of high labor intensity, low efficiency, occupation of labor, etc., so as to reduce the labor intensity of workers, reduce production costs, and have a high degree of automation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

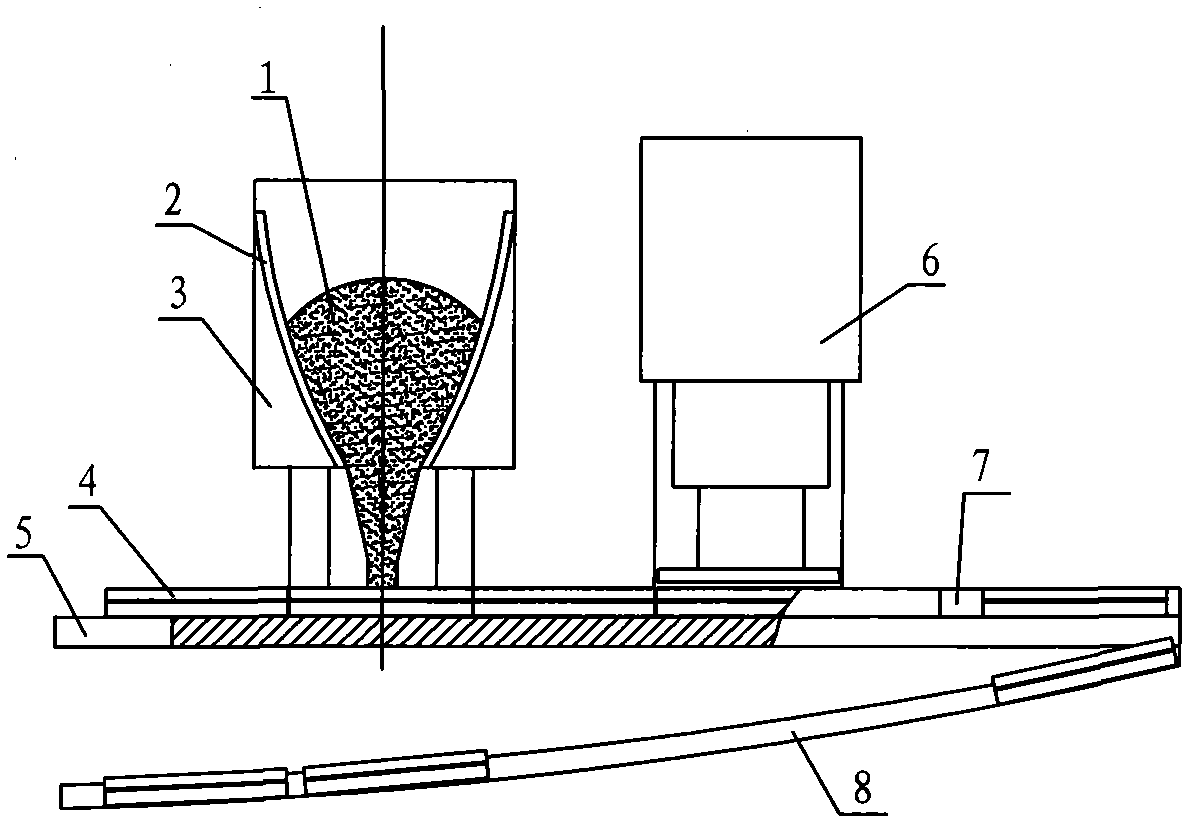

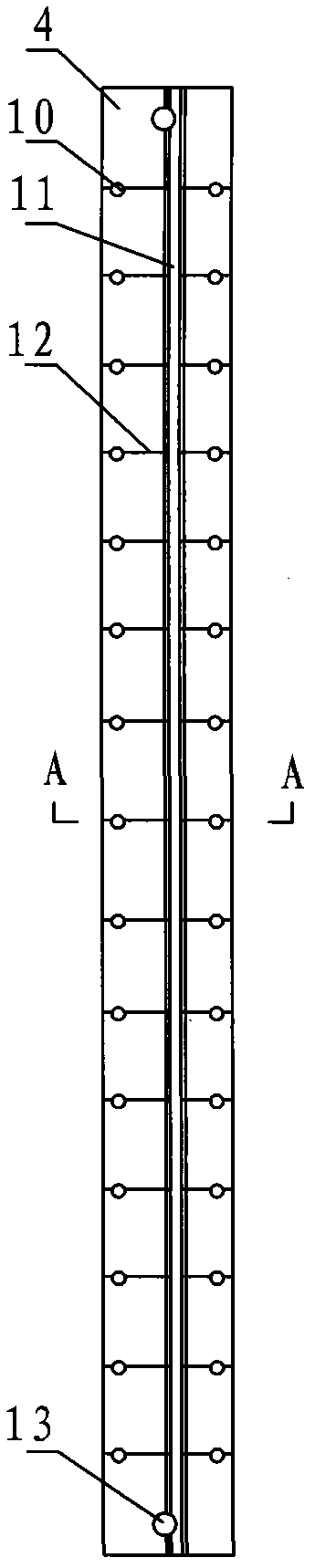

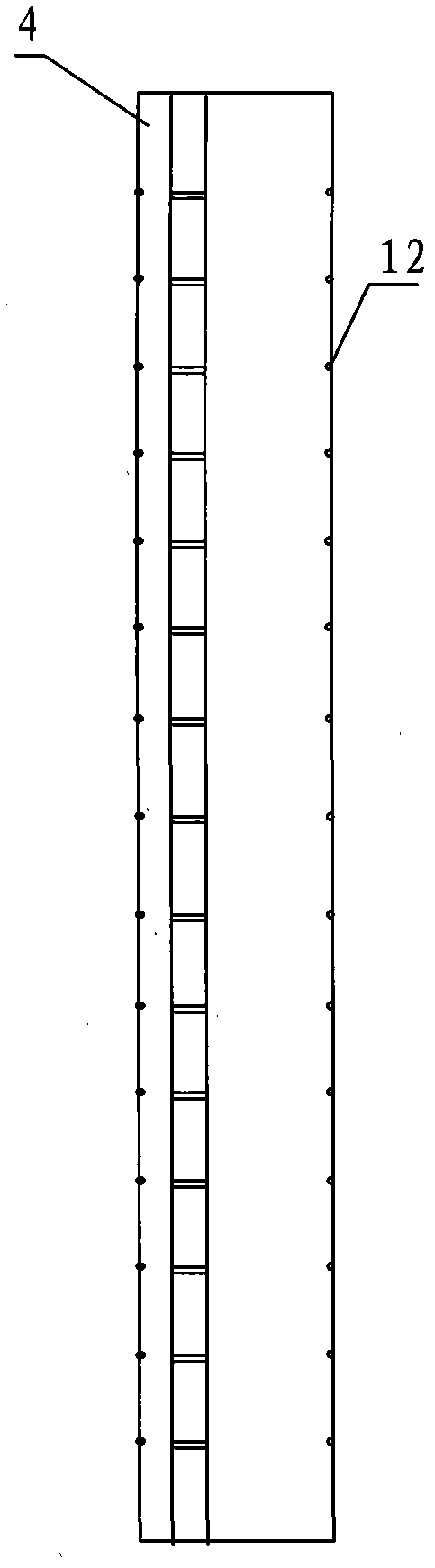

[0031] When the blood collection needle row die is used, the blood collection needle row die is sent into the funnel-type needle distributor, and the needle body leaks from the needle distributor and enters the needle groove on the surface of the blood collection needle row die brush. Both ends of the slot are located on the upper end of the magnet hole, and there are magnetic columns embedded in the hole, and the magnetic columns will attract and fix the two ends of the needle body in the needle slot, so that each needle slot retains a needle , and then the stamper is sent to the punching press for stamping. Because the groove in the middle of the upper surface of the stamper corresponds to the convex strip on the punch of the punching machine, the convex strip is pressed into the groove to punch the needle body out of a U-shaped bend. Since the position of the needle groove is consistent with the position of the needle body in the injection mold, the needles are arranged and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com