Novel wheat flour mill

A milling machine, a new type of technology, applied in cocoa, grain processing, food science, etc., can solve the problem of destroying the nutritional value of flour, achieve pure taste and improve processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

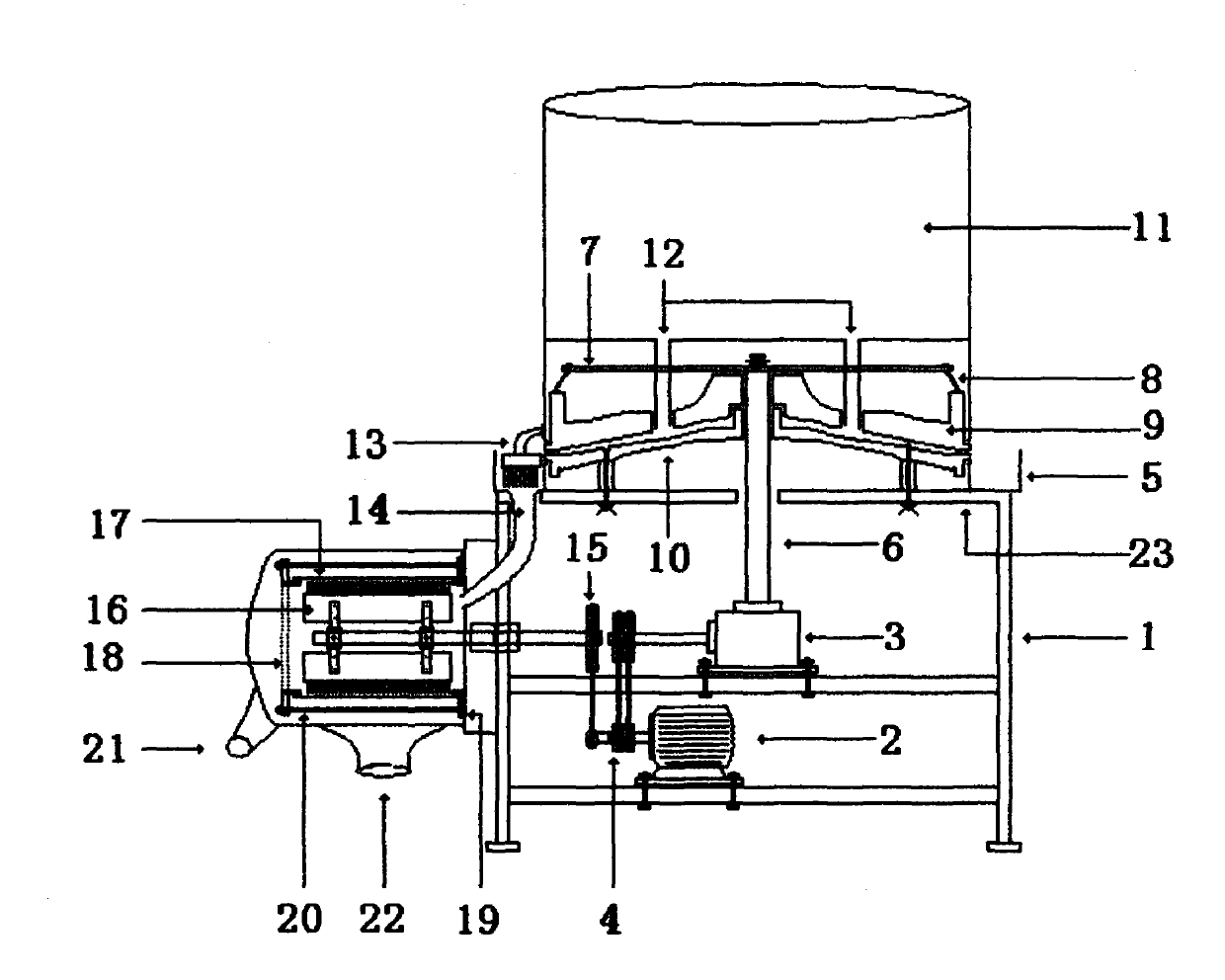

[0010] Such as figure 1 Shown is a preferred embodiment of the invention. The upper and lower grinding discs (9), (10) of the pulverizer adopt wear-resistant metal material casting, and its center through hole. The motor (2) and the reducer (3) are installed on the skeleton (1), and the output shaft of the reducer passes through the center hole of the lower and upper grinding discs installed on the same skeleton, and the pull rod (7) is rotated through the soft connection (8 ) to drive the upper grinding disc to rotate, the soft connection (8) adjusts the change of the feeding situation from the feeding port (12), and moves freely up and down. Rotate along a circular track to collect flour, the flour falls into the automatic noodle device from the feed port (14), the motor drives the brush (16) to rotate, the flour flows out from the noodle outlet (22) through the basket net (17), and the bran is Bran outlet (21) flows out.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap