Novel stainless steel submerged-arc welding wire for improving tensile strength after heat treatment

A tensile strength, stainless steel technology, used in welding equipment, welding media, welding/cutting media/materials, etc., can solve problems such as inability to meet technical requirements, and achieve the effect of improving tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

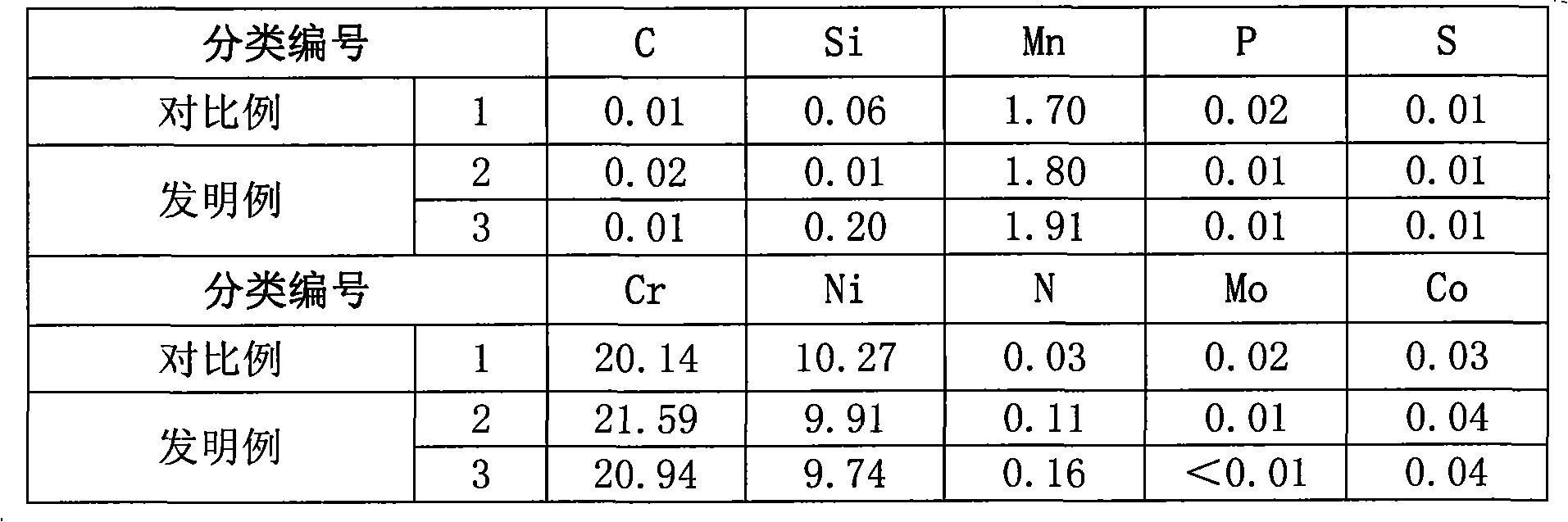

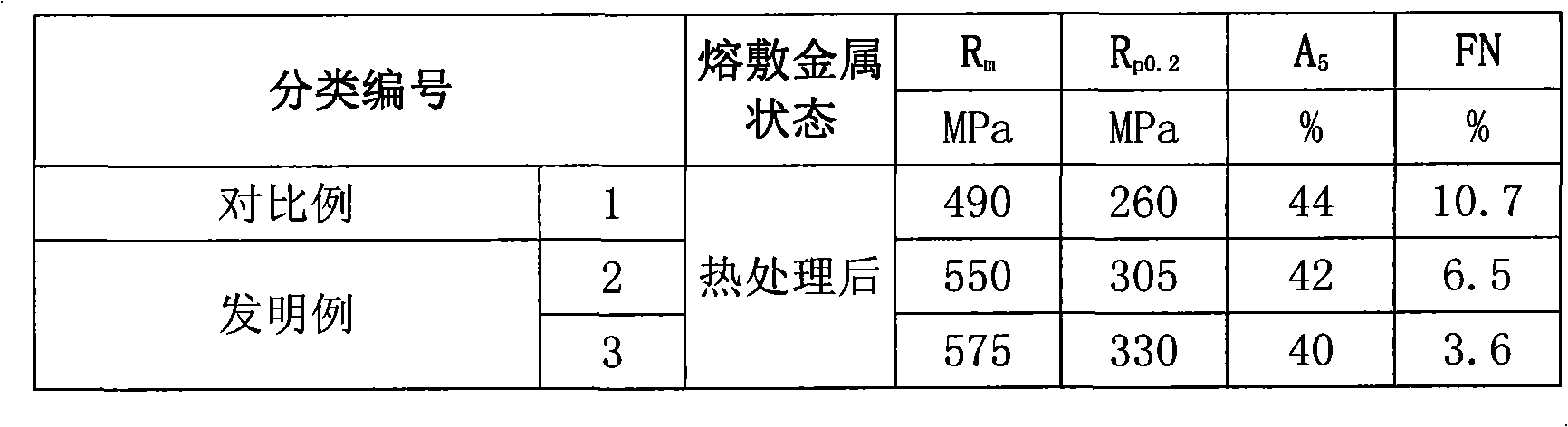

[0013] In order to better illustrate the advantages of the welding wire of the present invention, a comparative example and two examples of the invention are used to do a comparative test, the chemical composition and mechanical properties of the comparative example welding wire are basically the same as the existing three welding wires used for nuclear power units, and The welding wires of the two invention examples can meet the chemical composition and corresponding mechanical properties specified by the present invention.

[0014] The diameters of the three welding wires used in the test are all 4mm, and the supporting flux is SJ601H sintering flux. The welding process parameters are: welding current 550A, arc voltage 30V, welding speed 580mm / min, interlayer temperature ≤ 110°C. The mechanical properties and corrosion resistance of the deposited metal after heat treatment were measured respectively. The heat treatment process is: heating temperature 1080°C, holding time 20...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com