Aqueous thermally-foamed gluing adhesive plate

A thermal foaming, water-based technology that can be used in adhesive types, ester copolymer adhesives, film/sheet adhesives, etc., to solve problems such as migration and affecting the adhesion of acrylic emulsions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

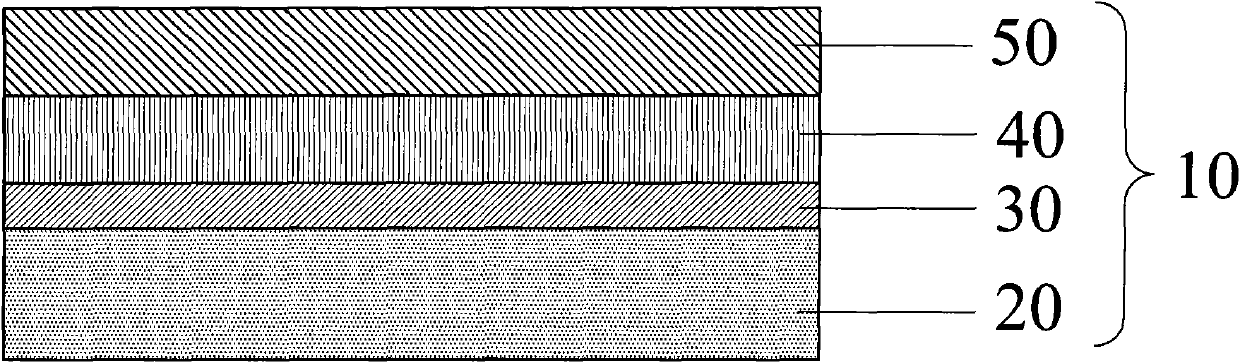

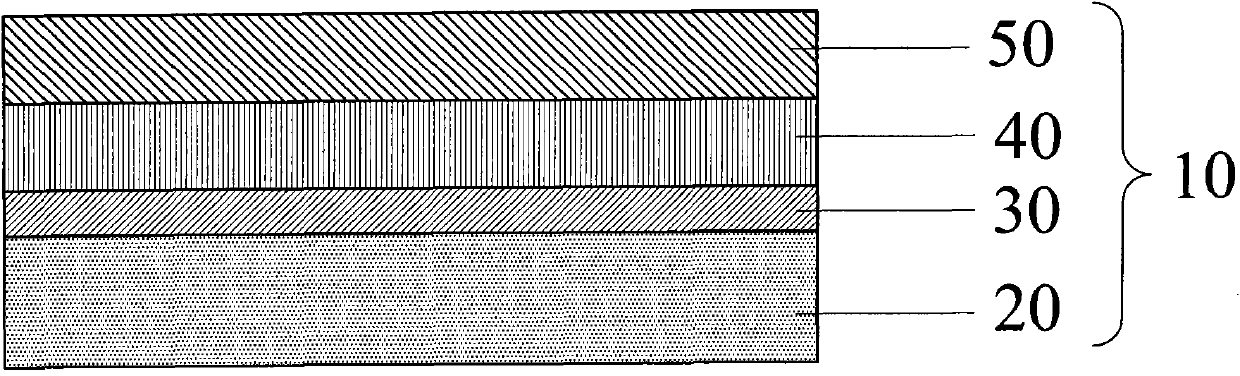

[0150] Such as figure 1 As shown, a 100-micron BH216 polyester film 20 (a PET film produced by Nan Ya Plastic Industry Co., Ltd.) is selected as the base material layer 20 of the water-based thermally foamed adhesive rubber sheet 10 .

[0151] When making the primer layer 30, take the prefabricated "primer acrylic emulsion" sample (P1) as the material, and take the solid content of the sample (P1) as 100 parts by weight, add 2 parts by weight of water-based isocyanate crosslinking agent 3100 (manufactured by Bayer) and 0.1 parts by weight of coupling agent KBM-503, and then adjusted together into "prime acrylic emulsion".

[0152] The prepared "primer acrylic emulsion" is directly coated on the surface-treated substrate layer 20 . After drying, a semi-finished product containing BH216 polyester film with a total thickness of 110-150 microns is obtained, wherein the thickness of the primer layer 20 is 10-50 microns.

[0153] When continuing to make the thermal foam adhesive l...

Embodiment 2

[0156] As in Example 1, but the "primer acrylic emulsion" component used to make the primer layer 30 is replaced by adding 4 parts by weight of water-based isocyanate-based crosslinking agent 3100; used to make the thermally foamed adhesive layer 40 The "heat-foaming pressure-sensitive adhesive" component is replaced by adding 3 parts by weight of foaming agent ES-81D.

[0157] After evaluating the adhesion of the finished product, the peelability after heating and the viscoelasticity of the rheometer, the results are shown in Table 3.

Embodiment 3

[0159] As in Example 2, but the "primer acrylic emulsion" component used to make the primer layer 30 is replaced with a prefabricated "primer acrylic emulsion" sample (P2); used to make thermal foaming The "thermal foaming pressure-sensitive adhesive" composition of the adhesive layer 40, with the acrylic emulsion sample (WB-2) of the prefabricated "thermal foaming pressure-sensitive adhesive" and adding 4 parts by weight of blowing agent ES- 81D replaced.

[0160] After evaluating the adhesion of the finished product, the peelability after heating and the viscoelasticity of the rheometer, the results are shown in Table 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com