TFT-LCD array substrate and method for manufacturing the same

A technology of an array substrate and a manufacturing method, applied in the field of liquid crystal display, can solve the problems of reducing the aperture ratio of the liquid crystal display device, affecting the display effect of the liquid crystal display device, etc., and achieve the effect of increasing the size and increasing the facing area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

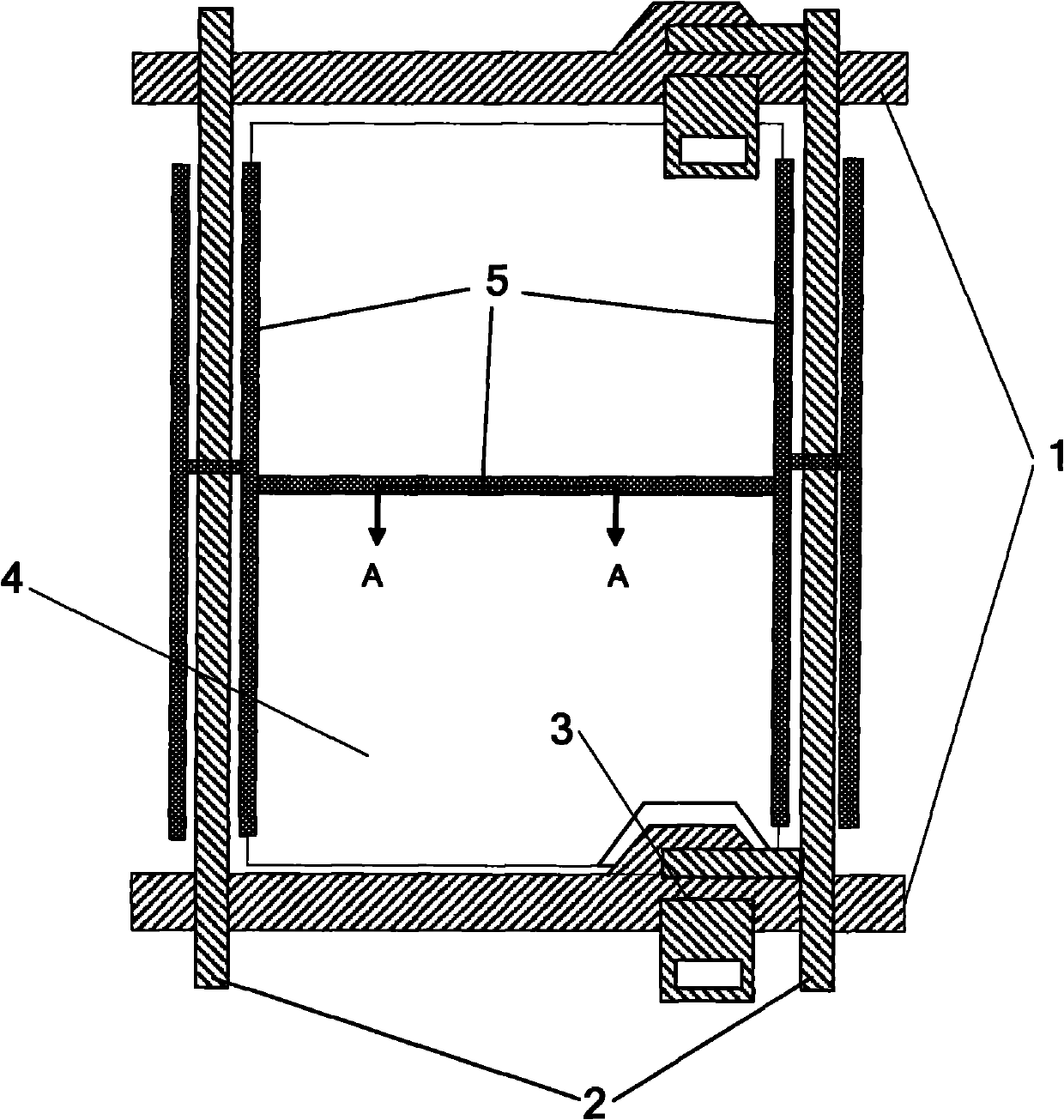

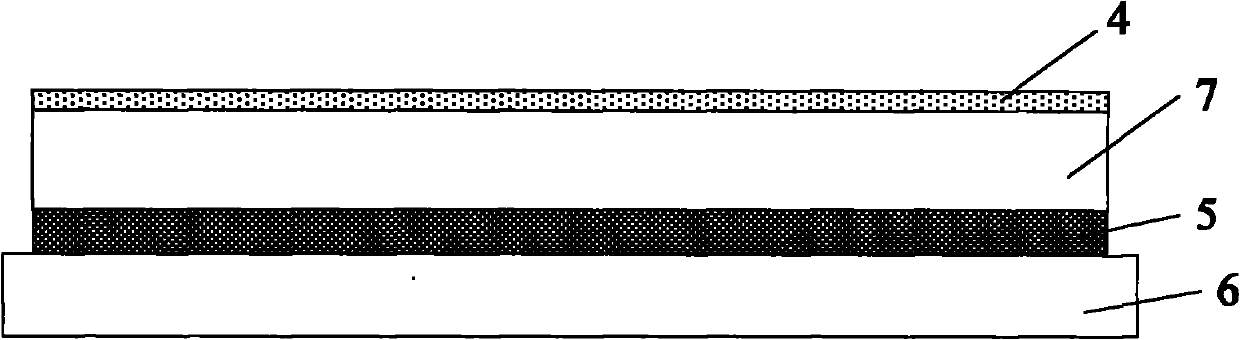

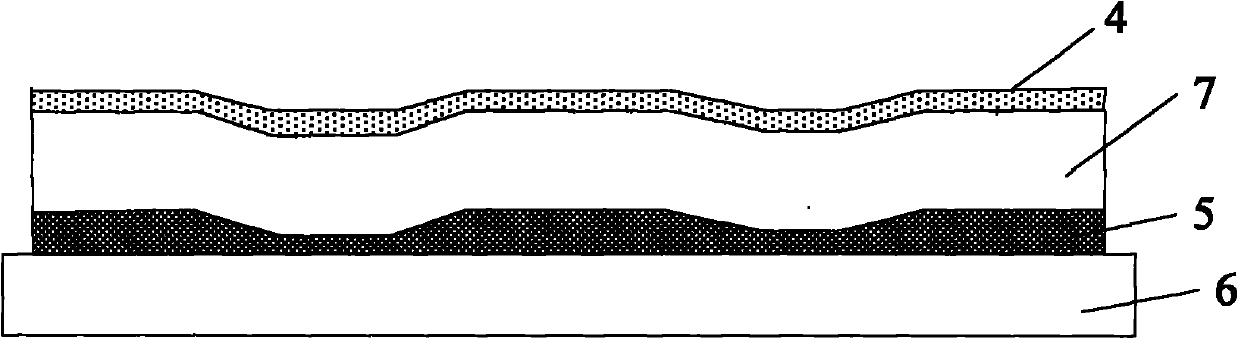

[0032] An embodiment of the present invention provides a TFT-LCD array substrate, combined with image 3 As shown, the TFT-LCD array substrate provided in this embodiment includes a glass substrate 6, and a common electrode line 5, an insulating layer 7, and a pixel electrode 4 sequentially formed on the glass substrate 6; the pixel electrode 4, the insulating layer 7, and the common The combination of the electrode lines 5 constitutes the storage capacitor Cst; in addition, a corresponding concave-convex structure is formed on the surface of the common electrode line 5 and in the region of the pixel electrode 4 facing the common electrode line 5 .

[0033] On the above-mentioned TFT-LCD array substrate, since the surface of the common electrode line 5 and the area facing the common electrode line 5 on the pixel electrode 4 are designed with corresponding concavo-convex surfaces, so that without increasing the line width It also achieves the effect of increasing the facing are...

Embodiment 2

[0041] For the above TFT-LCD array substrate, the embodiment of the present invention also provides a TFT-LCD array substrate manufacturing method, such as Figure 6 shown, including:

[0042] The bottom electrode of the storage capacitor and the pixel electrode are formed on the substrate, so that the area opposite to the bottom electrode of the storage capacitor and the pixel electrode has a corresponding concave-convex structure.

[0043] Specifically, the process of forming the bottom electrode of the storage capacitor and the pixel electrode on the substrate includes:

[0044] Deposit a metal thin film on the substrate, and form the bottom electrode of the storage capacitor with a concave-convex structure on the surface through a patterning process;

[0045] An insulating layer and a pixel electrode layer are formed.

[0046] Wherein, the slope angle of the concave-convex structure is smaller than 90°.

[0047] In addition, in the above process, the concave-convex stru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com