Efficient and controllable constant current source circuit

A constant current source and circuit technology, which is applied in the direction of adjusting electrical variables, control/regulation systems, instruments, etc., can solve the problems of inconvenient control, low efficiency of mirror current source, and inability to use digital control to achieve temperature stability Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

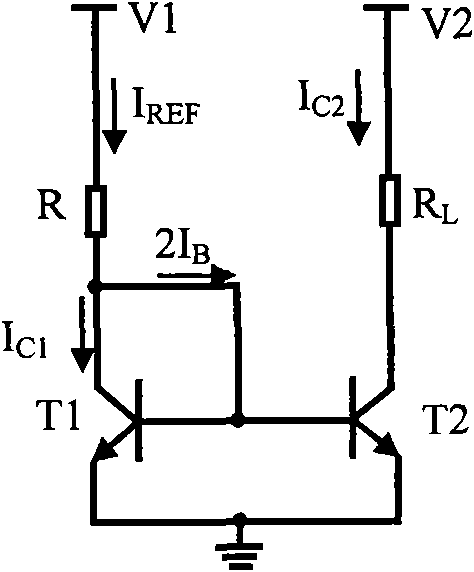

Problems solved by technology

Method used

Image

Examples

Embodiment 1

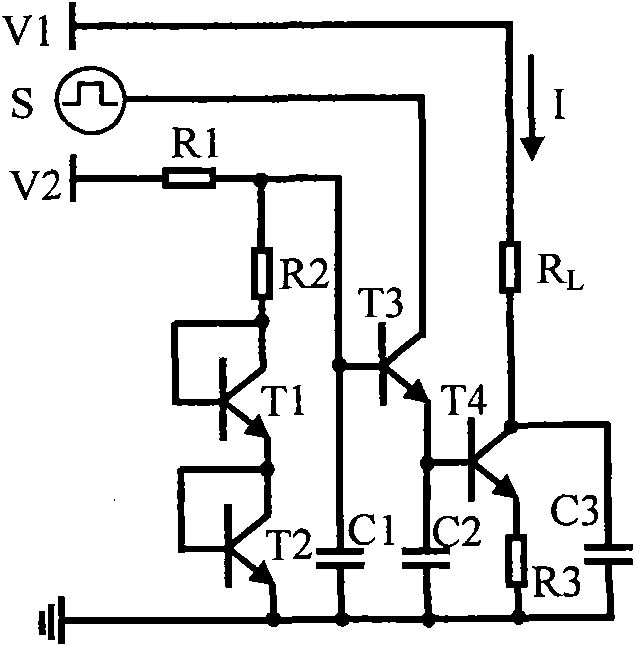

[0026] Preferred embodiment of the present invention is described in detail as follows in conjunction with accompanying drawing: See figure 2 , the high-efficiency controllable constant current source circuit includes four transistors T1, T2, T3, T4, three resistors R1, R2, R3 and one load RL. T1 and T3, T2 and T4 are packaged in two pairs of tubes respectively, T1 tube to T3 tube, T2 tube to T4 tube for temperature compensation. C1, C2 and C3 are mainly to prevent overshoot, and their value is around 1nF, which is adjusted according to the frequency of the control signal S. from figure 2 It can be seen from the circuit of high-efficiency controllable constant current source that the base voltage of transistor T3 is:

[0027] V b 3 = V b 1 + V b 2 + V ...

Embodiment 2

[0034] In LED backlighting and lighting applications, LEDs must be driven by a constant current source with a current of about 20mA. Using the high-efficiency controllable constant current source drive of the second embodiment such as image 3 As shown, if the reference voltage V2 is 12V, R1 is 18.2K ohms, R2 is 3K ohms, and R3 is 75 ohms. Therefore, the constant current source current, that is, the LED drive current is

[0035] I = 20.000 mA + Δ VR 2 ( R 1 + R 2 ) R 3

[0036] = 20.000 mA + 1.89 ΔVmA

[0037] If the error of the reference voltage is less than 0.2V...

Embodiment 3

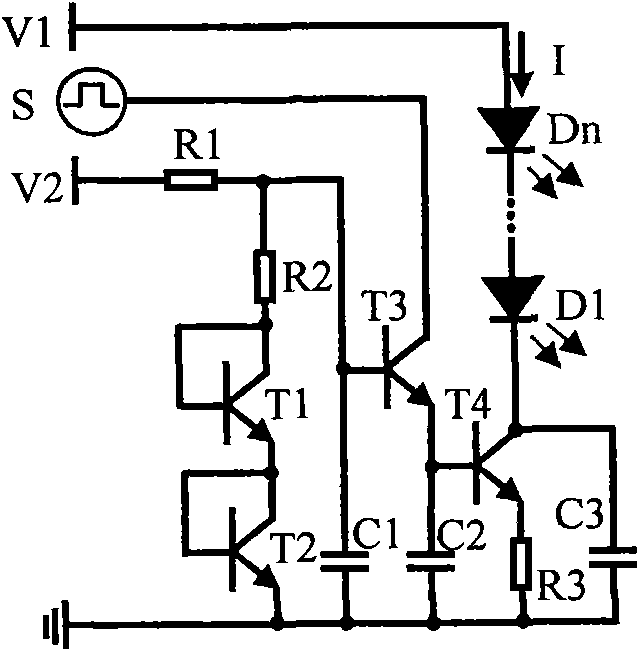

[0039] If multiple high-efficiency controllable constant current sources are required in the application, and the current of each branch is the same, the third example of this embodiment Figure 4 The method shown is extended to save components and reduce cost. T4, T5, ..., Tn use the same type of triode, and their power consumption is basically the same. T2 tube also has a temperature compensation function for T4, T5, ..., Tn tube, and the temperature stability of the constant current source is guaranteed. Therefore, after expansion, the advantages of the high-efficiency controllable constant current source still exist.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com