Microresistor assembly

A technology of micro-resistors and components, applied in the manufacture of resistor parts, resistors, resistors, etc., can solve the problems of limited operating power, short circuit, limited heat dissipation effect, etc., to achieve increased heat dissipation area and accurate measurement results , The effect of improving thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Relevant technical content and detailed description of the present invention, cooperate drawing description as follows:

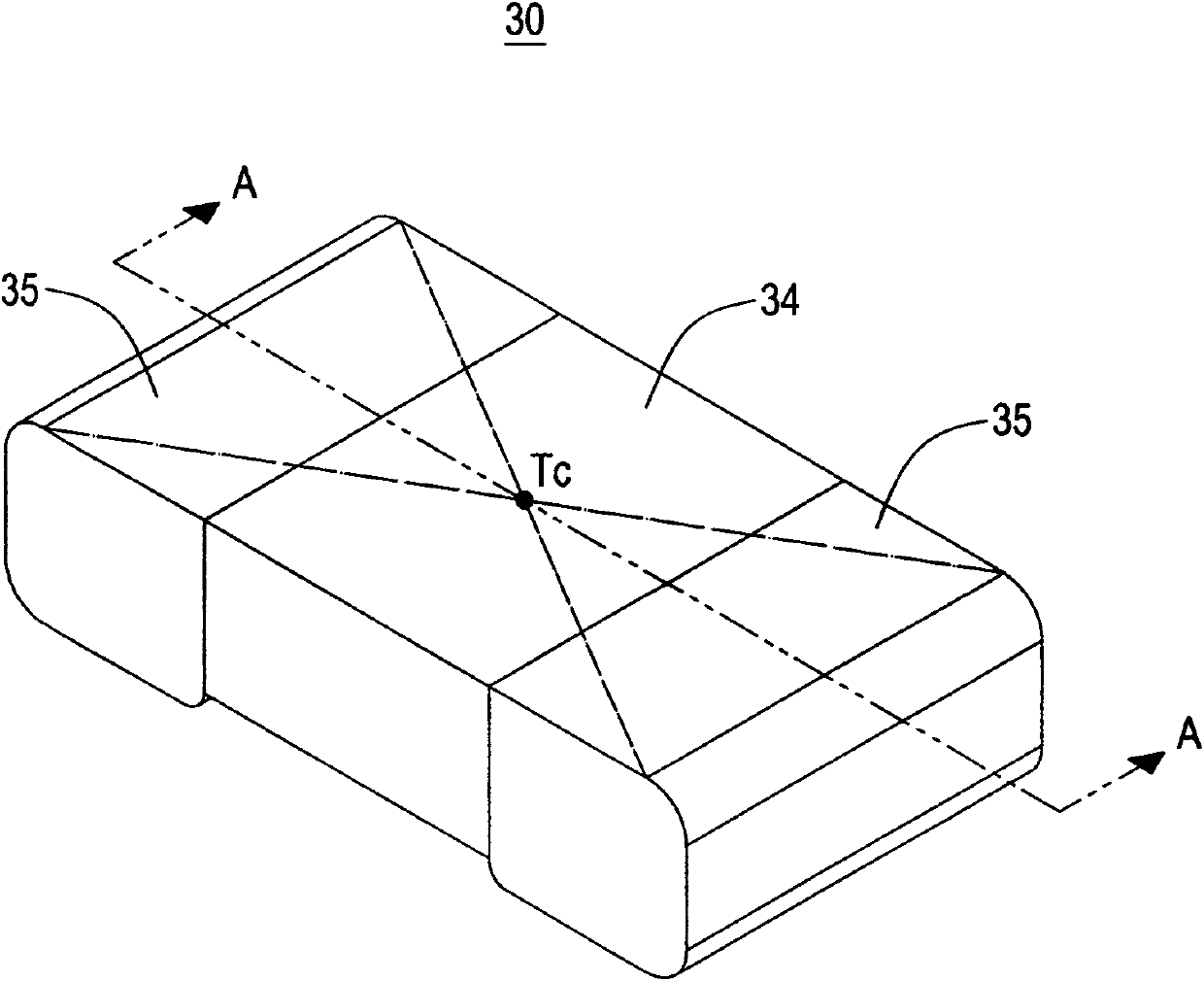

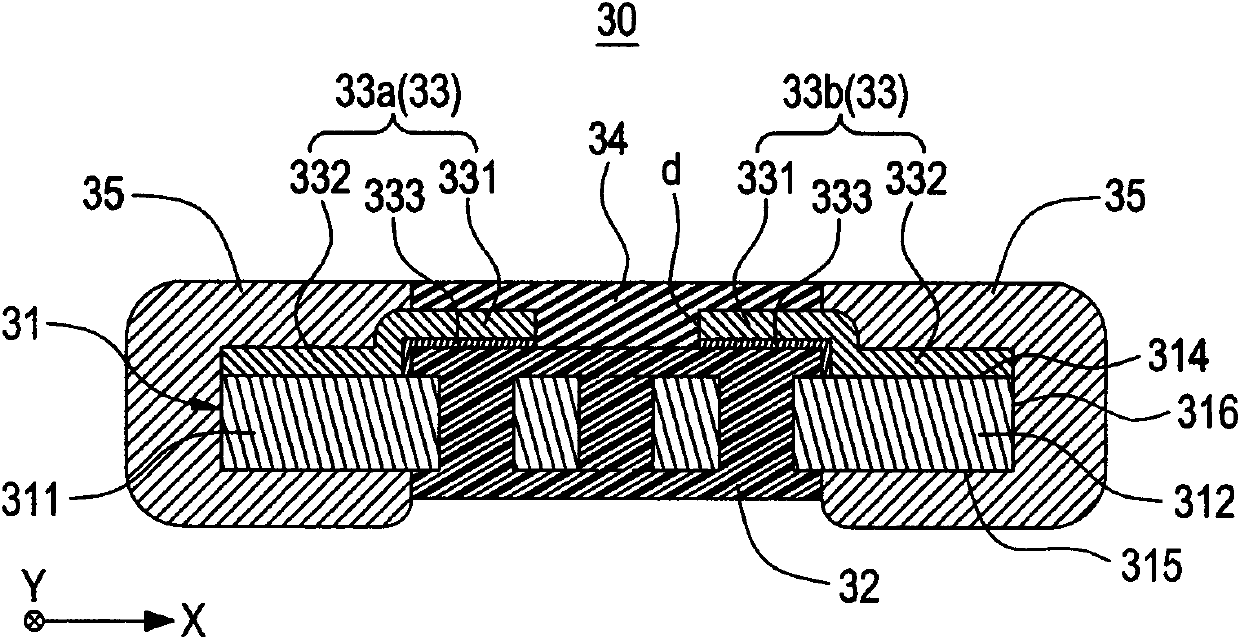

[0043] refer to figure 1 and figure 2 The micro-resistor assembly 30 of the first preferred embodiment of the present invention includes a resistor body 31 , a first protection layer 32 , at least one heat conduction layer 33 , a second protection layer 34 , and two electrode layers 35 .

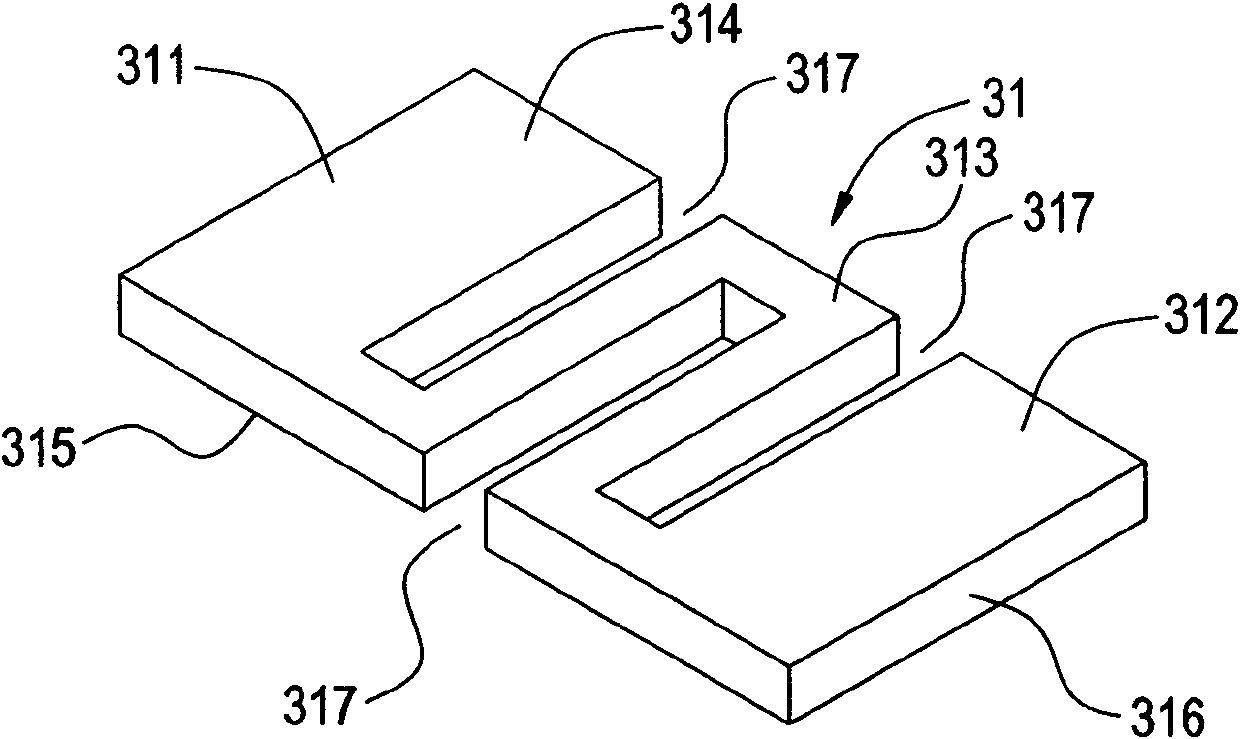

[0044] refer to image 3 , the resistor body 31 is a metal sheet and has a first end portion 311, a second end portion 312 opposite to the first end portion 311 and a central portion 313 between the first end portion 311 and the second end portion 312 . The resistor body 31 also has a first surface 314 , a second surface 315 opposite to the first surface 314 , and a plurality of side surfaces 316 connecting the first surface 314 and the second surface 315 . In this embodiment, the central portion 313 of the resistor body 31 has a plurality of through holes 317...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com