Light emitting diode driving circuit

A technology of light-emitting diodes and driving circuits, which is applied in the direction of circuit layout, lamp circuit layout, light source, etc., can solve the problems of accelerating light-emitting diode light decay and burning, poor lighting device efficiency, and affecting the normal operation of light-emitting diode modules, etc., to achieve good assembly The effect of flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

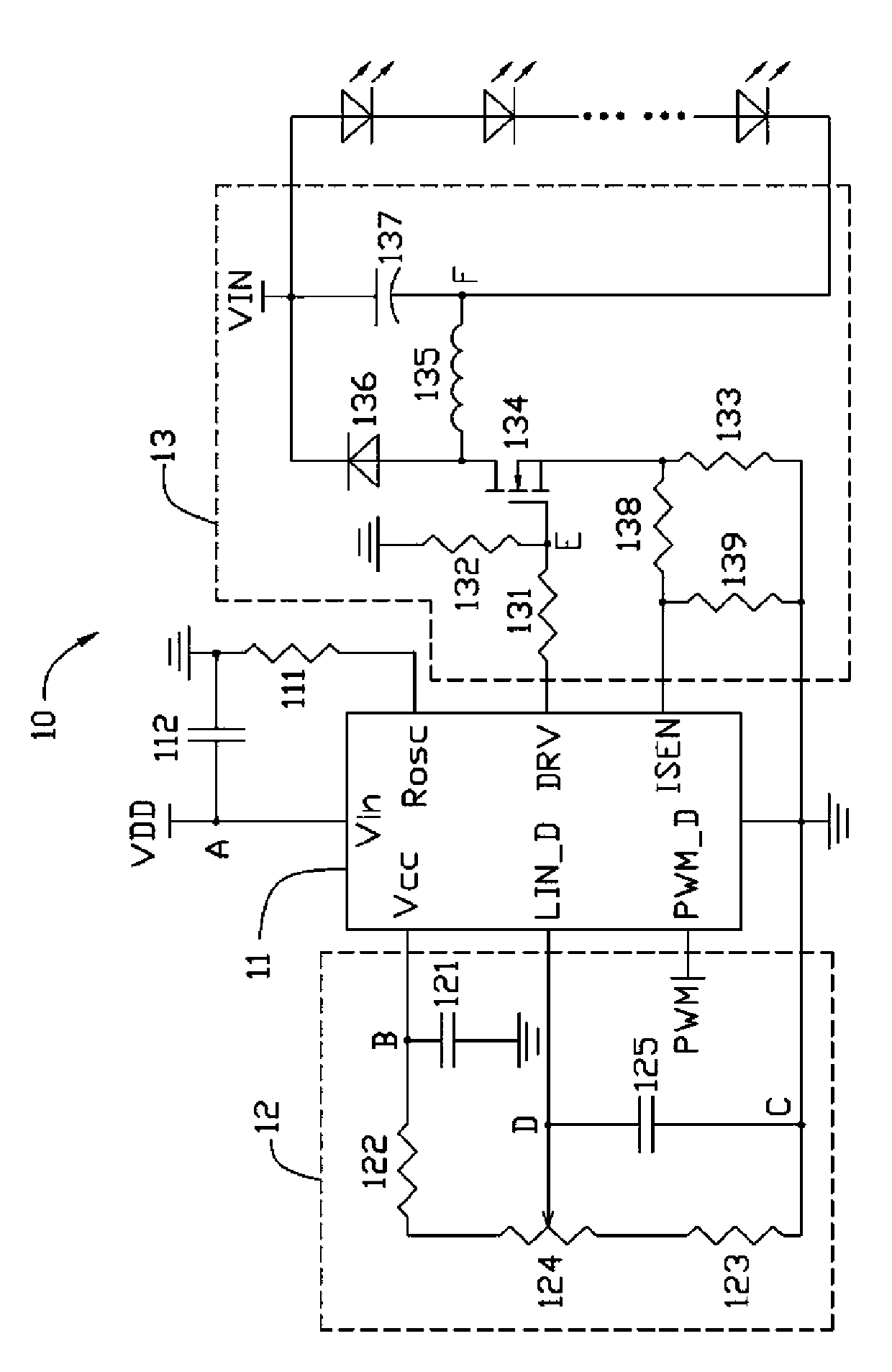

[0010] See figure 1 , an LED driving circuit 10 provided by an embodiment of the present invention includes a pulse width modulation control chip 11 , an input unit 12 and an output unit 13 .

[0011] The pulse width modulation control chip 11 is provided with a plurality of basic pins, which include a Vin pin, a Vcc pin, a LIN_D pin, a PWM_D pin, a GND pin, an ISEN pin, a DRV pin, and a Rosc pin . In this embodiment, the PWM control chip 11 is an integrated chip FP6700, which can support high voltage and buck architectures, and its output current can be greater than 1 ampere. Among them, the integrated chip FP6700 is a driver chip disclosed by Tianyu Technology Co., Ltd. on April 1, 2008.

[0012] The Vin pin of the integrated chip FP6700 is electrically connected to an external voltage VDD, and the electrical connection is defined as a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com