Anti micro-pitting industrial gear oil composition

An industrial gear oil, anti-micro-pitting technology, applied in the field of lubricating oil, can solve the problems of loss of metal material on the tooth surface, affecting the life of the gear, changing the geometric size of the gear, etc., to inhibit pitting corrosion, improve lubrication stability, and ensure normal operation. running effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

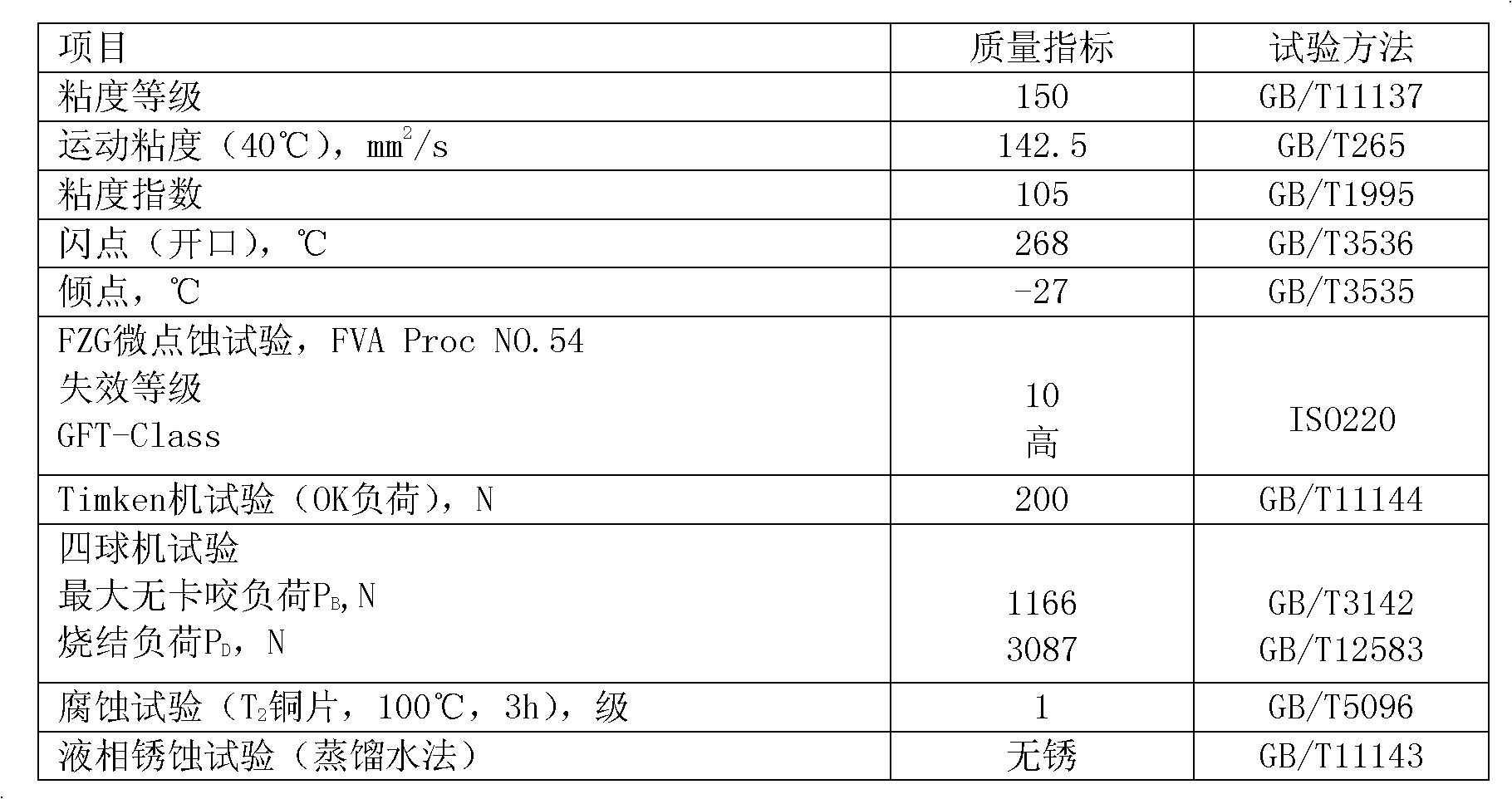

Embodiment 1

[0030] Anti-micropitting industrial gear oil composition, its components are proportioned as follows by weight percentage:

[0031] Mineral base oil 150BS: 55.8%, mineral base oil 150N: 35.38%, polyalphaolefin pour point depressant: 0.3%, polyester: 6.0%, sulfur phosphorus nitrogen compound extreme pressure antiwear agent: 1.6%, borate extreme pressure Antiwear agent: 0.2%, Ciba Irganox phenolic antioxidant: 0.5%, amine phosphate mixture rust inhibitor: 0.2%, acrylate non-silicon antifoaming agent: 0.02%.

[0032] Its preparation method is to firstly mix mineral base oil, polyester and polyalphaolefin pour point depressant and heat it to a temperature of 60-70°C. After mixing for 0.5-1 hour, add extreme pressure anti-wear agent, antioxidant, rust inhibitor, Anti-foaming agent, after reconciling at 50-60°C for 2-4 hours, the analysis and testing of viscosity, viscosity index, anti-emulsification, anti-foaming property and other items can be carried out, and the finished product...

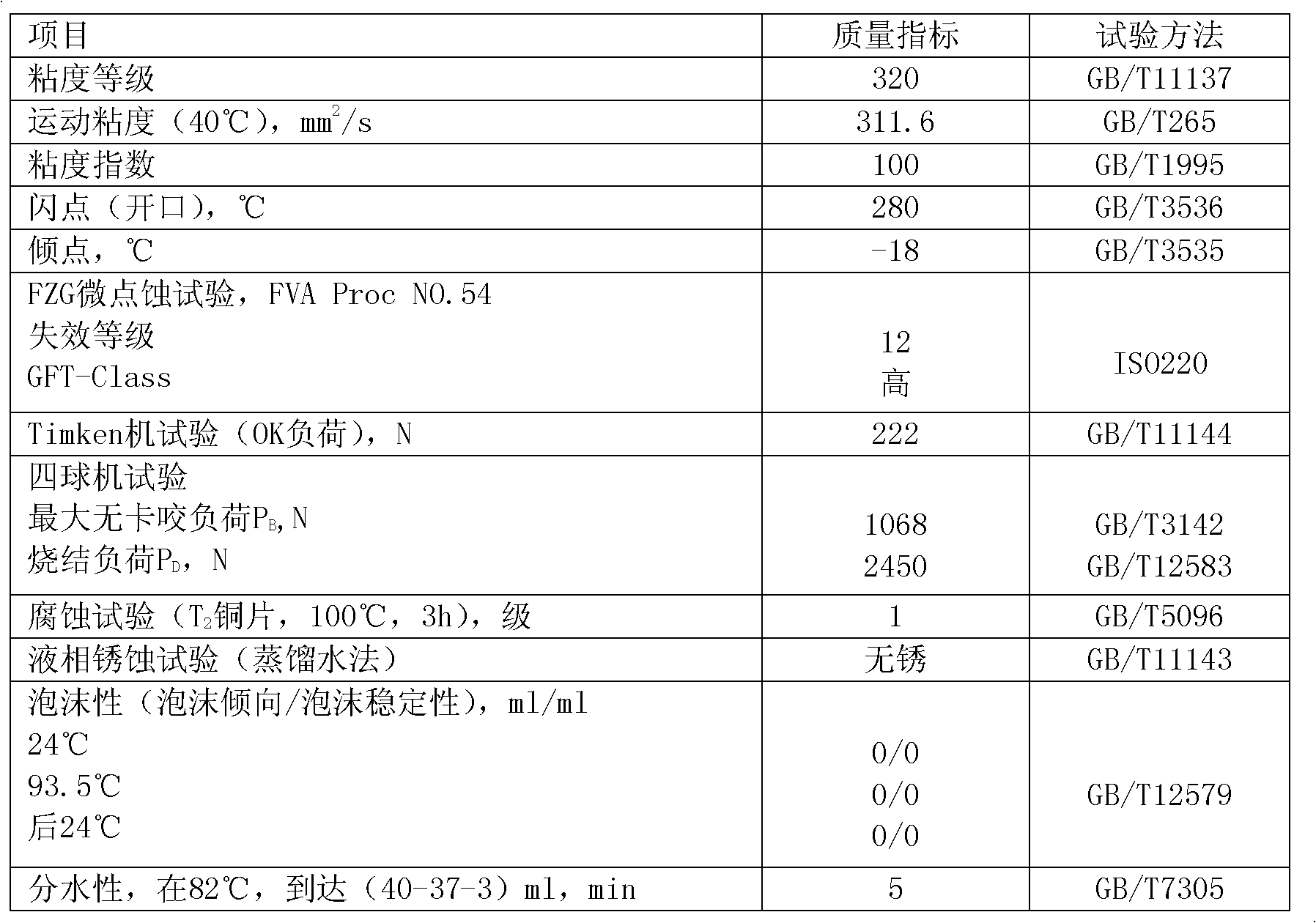

Embodiment 2

[0038] Anti-micropitting industrial gear oil composition, its components are proportioned as follows by weight percentage:

[0039] Mineral base oil 150BS: 70.67%, mineral base oil 500N: 18%, polyalphaolefin pour point depressant: 0.5%, polyester: 8.0%, sulfur phosphorus nitrogen compound extreme pressure antiwear agent: 1.7%, borate extreme pressure Antiwear agent: 0.3%, Ciba Irganox phenolic antioxidant: 0.6%, phosphate amine mixture antirust agent: 0.2%, acrylate non-silicon antifoaming agent: 0.03%.

[0040] The preparation method is the same as in Example 1.

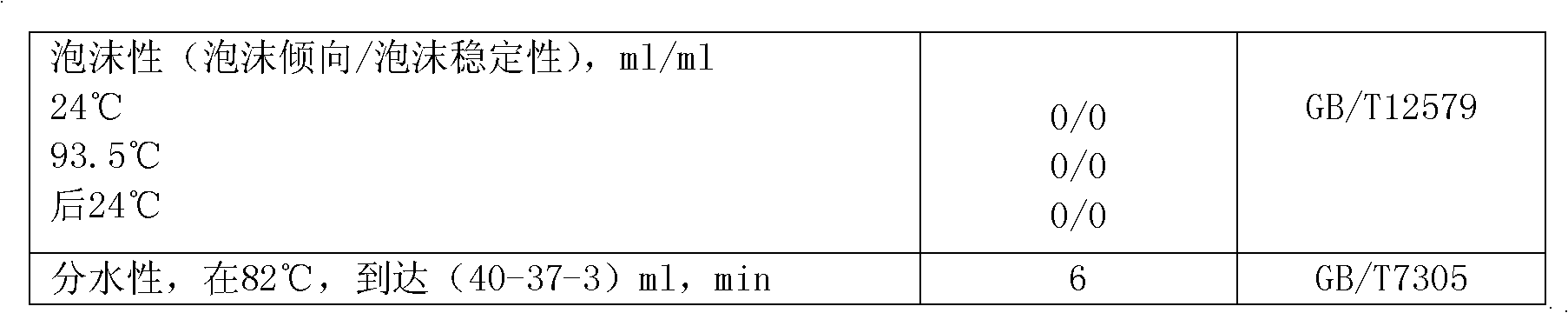

[0041] After testing, this ratio is 320 viscosity grade anti-micropitting industrial gear oil. The specific performance test results are shown in Table 2.

[0042] Table 2 Example 2 Anti-micropitting industrial gear oil performance testing results

[0043]

[0044] Example 2

[0045] Anti-micropitting industrial gear oil composition, its components are proportioned as follows by weight percentage:

[0046] Mi...

Embodiment 3

[0049] Table 3 Example 3 Anti-micropitting industrial gear oil performance testing results

[0050]

[0051] In the above embodiments, the extreme pressure antiwear agent of sulfur phosphorus nitrogen compound is one or both of trialkylamines, trihydroxy phosphorothioate, thiadiazole compounds or dithiocarbamate compounds. mixture of the above. Hydrorefined mineral base oil 150N, 450N, 500N has a kinematic viscosity of 20-100mm at 40°C 2 / s, the kinematic viscosity of bright stock 150BS at 40°C is 400-500mm 2 / s. Ciba Irganox phenolic antioxidant can be replaced by one or a combination of octyl butyl dianiline and 2,6-di-tert-butyl p-cresol or combined with octyl butyl dianiline and 2,6-di One or two kinds of tert-butyl-p-cresol are used in combination; polyester is a high molecular weight polymer of polyol fatty acid ester, with a molecular weight of 15,000-25,000 and a kinematic viscosity of 2,100-12,000mm at 40°C 2 / s, the viscosity index is 200-260, and the thermal w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com