Tunneling construction Ttechnology for constructing mined tunnelof by adopting composite tooth support through mining method

A technology of tunnel construction and mining method, applied in tunnels, tunnel linings, mining equipment and other directions, can solve the problems of easy deformation of segments, difficult to control the line shape, etc., to achieve the effect of fast and convenient construction, time saving, good positioning and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] 1. The technological process of the composite tooth support method through the mine tunnel:

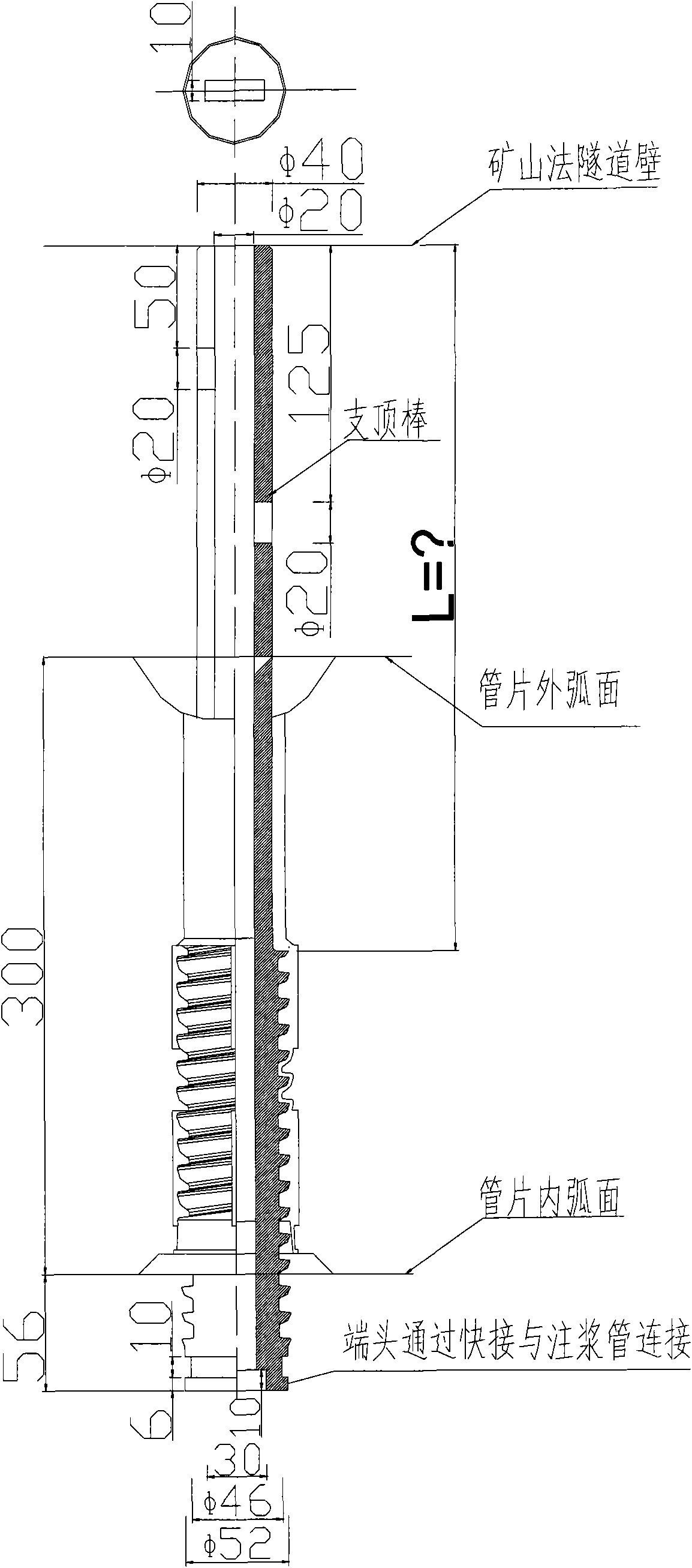

[0015] (1) Processing composite tooth abutment (material is steel);

[0016] (2) Open up the original grouting hole after the segment is installed, use the original grouting hole to install the composite tooth abutment as a support, let the segment fall naturally on the guide platform after it is separated from the shield tail, and use the composite tooth abutment and longitudinal The pulling force of the bolts together properly restrict the segments;

[0017] (3) Spray pea gravel between the lower part of the segment and the tunnel wall and synchronously inject grout during the excavation of the shield machine;

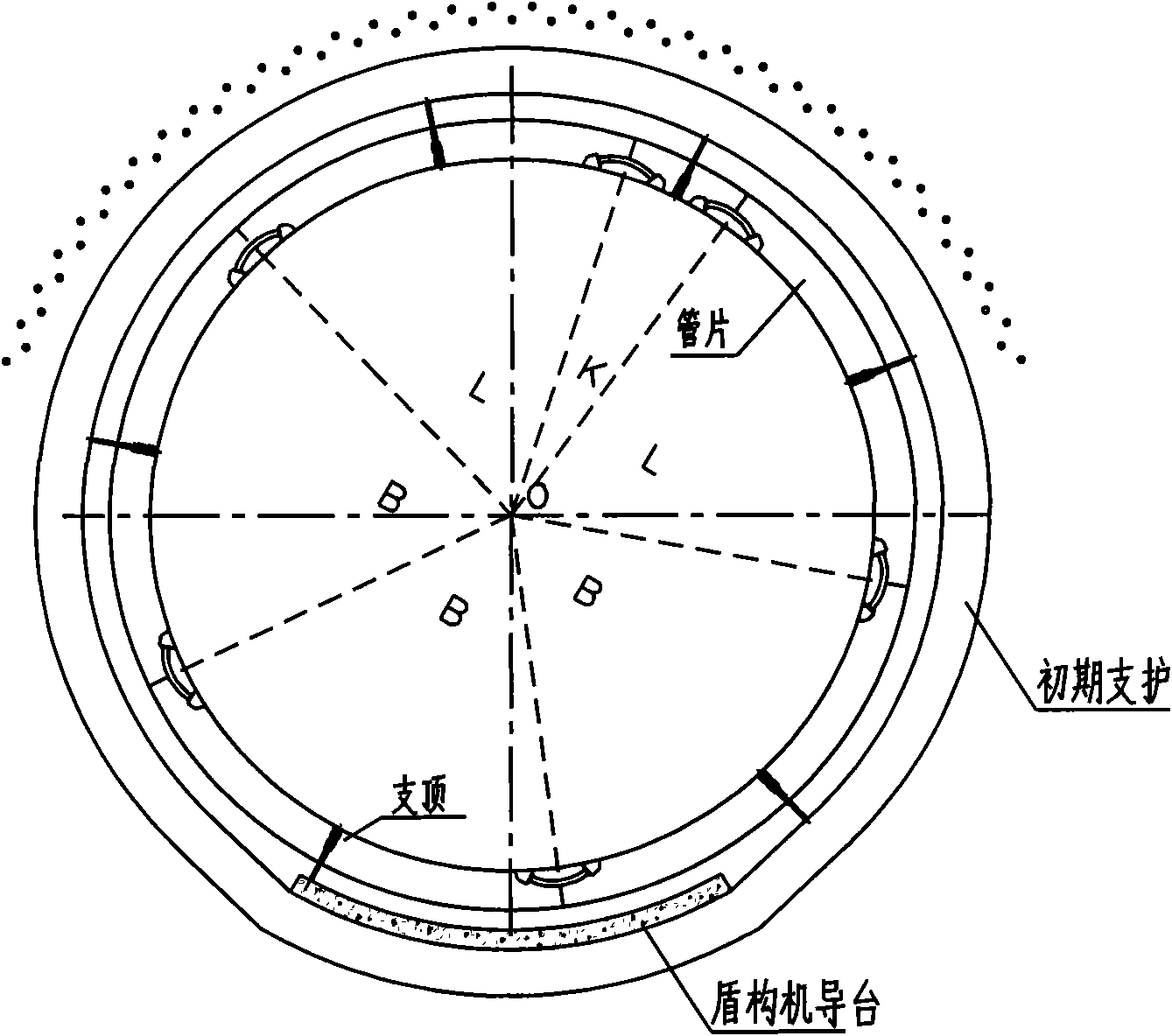

[0018] (4) The shield machine passes through the mine method tunnel, and the roof support is installed as follows figure 1 As shown in Fig. 1, through the excavation section, the shield machine properly applies thrust to compress the segments in the tunnel, tighten ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com