Pipeline robot driving mechanism

A pipeline robot and drive mechanism technology, applied in the field of robots, can solve problems such as relatively high requirements for brush materials, failure to work normally, robot stuck, etc., and achieve the effect of novel design, low cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

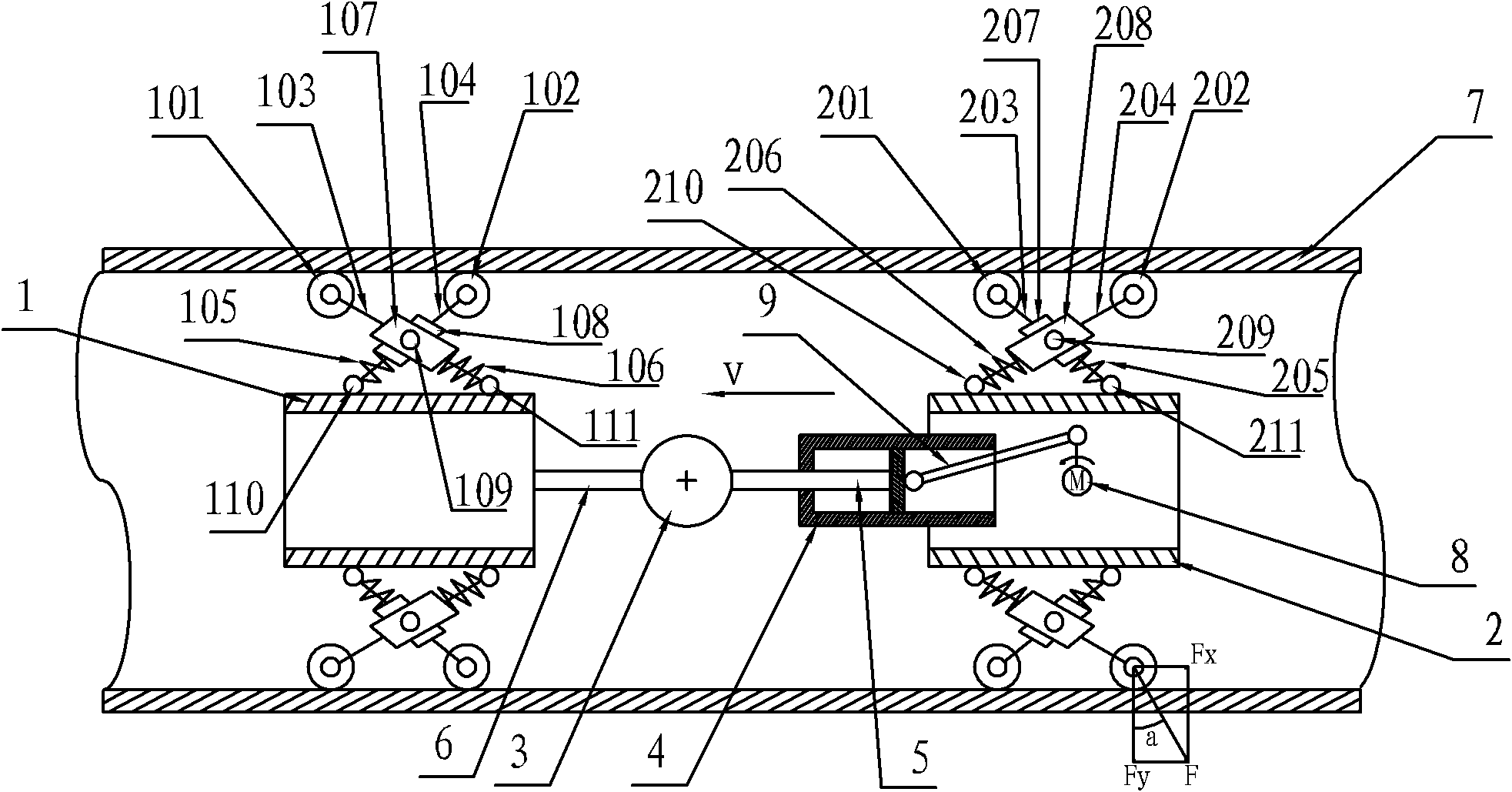

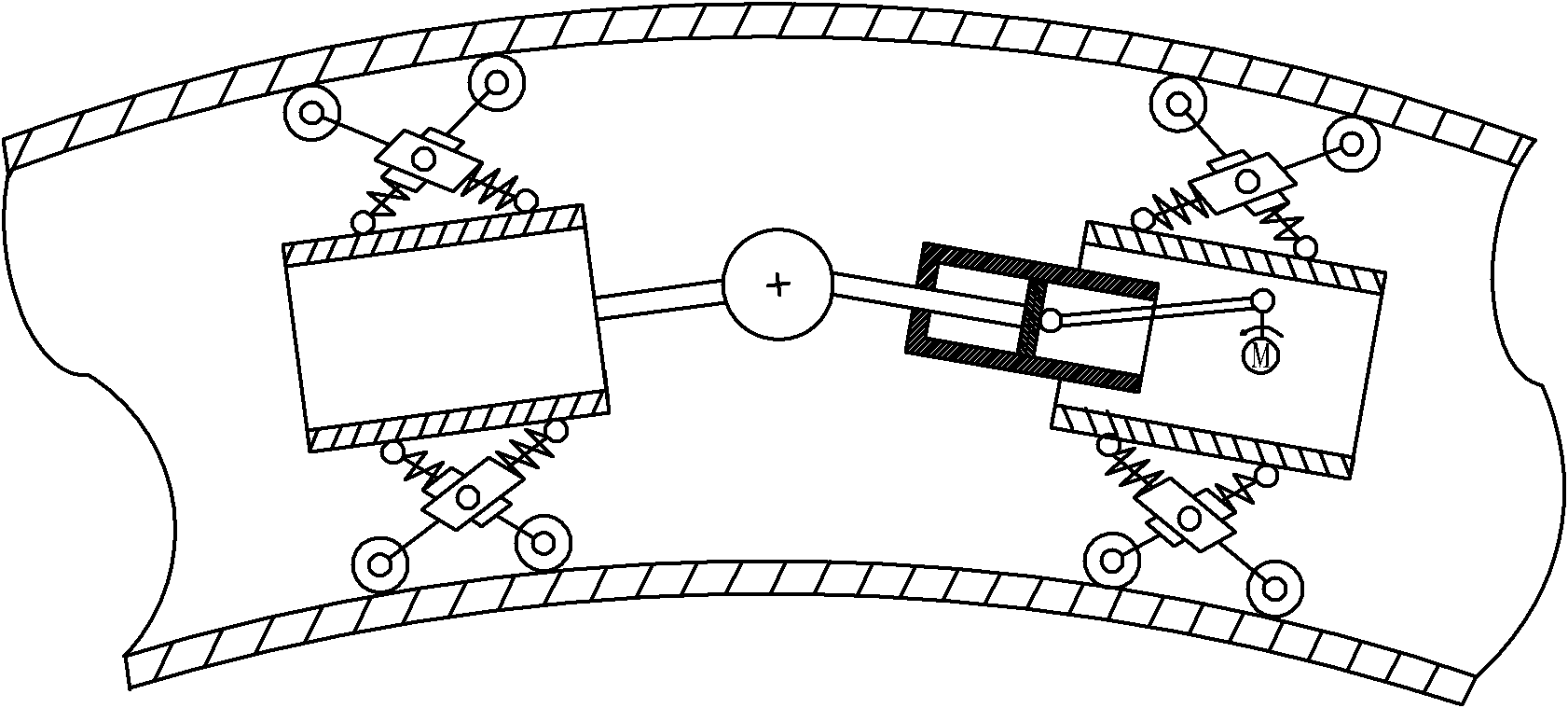

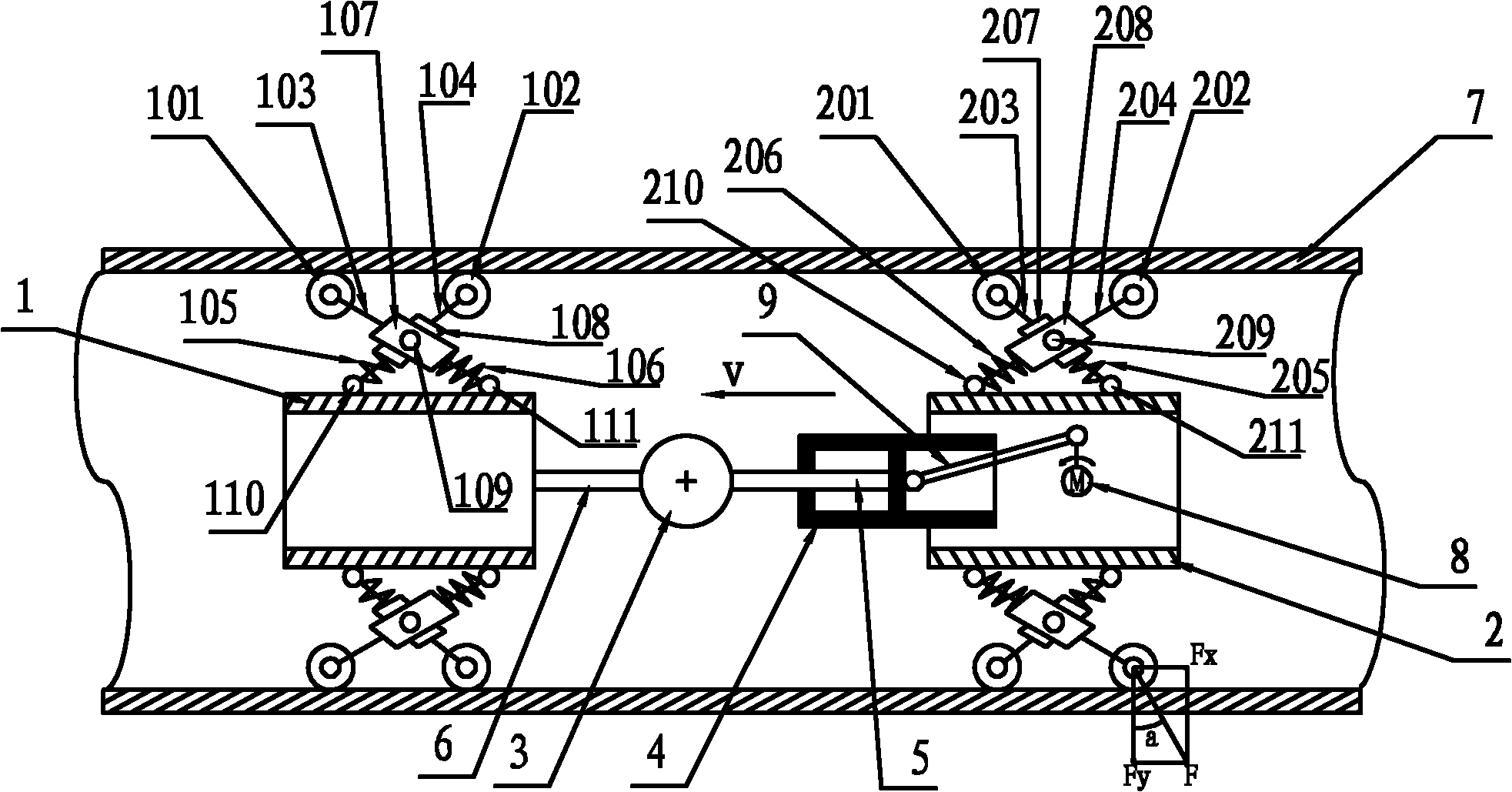

[0013] Such as figure 1 , this kind of pipe robot driving mechanism, which is composed of a front frame 1 and a rear frame 2 that are all located in the pipeline 7, and the front frame and the rear frame are connected by a universal joint 3.

[0014] The front frame 1 includes a front frame tube located in the center of the pipeline and three groups of front walking structures that can only move in one direction and are hinged on the outer circumference of the frame tube at 120 degrees. The front walking structure includes The first roller 101 of free rolling and the second roller 102 with one-way ratchet; The second roller pole 104 is long; the first roller pole 103 is connected to the second hinge point 111 after passing through the inner cavity of the first spring barrel 107 and the second spring 106, and the second roller pole 104 passes through the second spring barrel 108 The cavity and the first spring 105 are connected on the first hinge point 110; the outer wall of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com