Method for manufacturing micromechanical shutter

A manufacturing method and shutter technology, which are applied in opto-mechanical equipment, patterned surface photoengraving process, and microstructural technology, etc., can solve the problems of difficult shutter structure materials, low fatigue strength, low reliability, etc., and achieve good results. Space environment adaptability, low cost, improved performance and functionality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

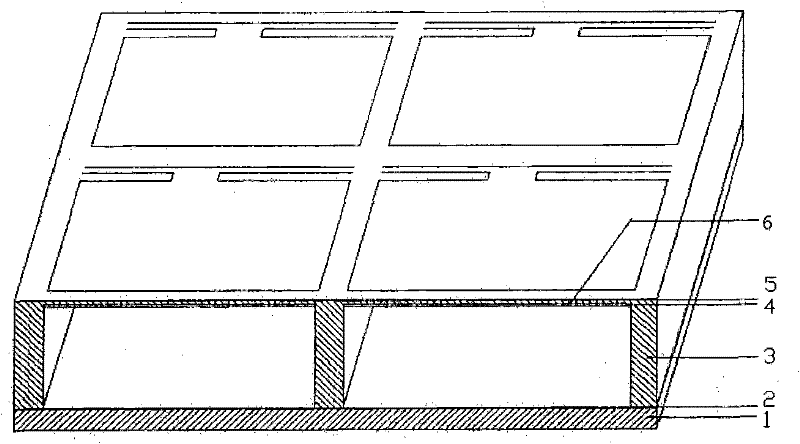

[0032] 1. Select a stainless steel substrate with a size of 50mm×50mm×0.8mm, soak it in dilute nitric acid for 15 minutes to remove the oxide on the surface of the stainless steel sheet, then soak it in concentrated alkali solution for 20 minutes to remove the oil on the surface of the stainless steel sheet, and finally use it Dry in deionized water after cleaning;

[0033] 2. On the upper and lower surfaces of the stainless steel substrate processed in step 1, prepare a layer of positive SU-8 photoresist by spraying method, and pre-cure the photoresist for 30 minutes at 85 degrees Celsius;

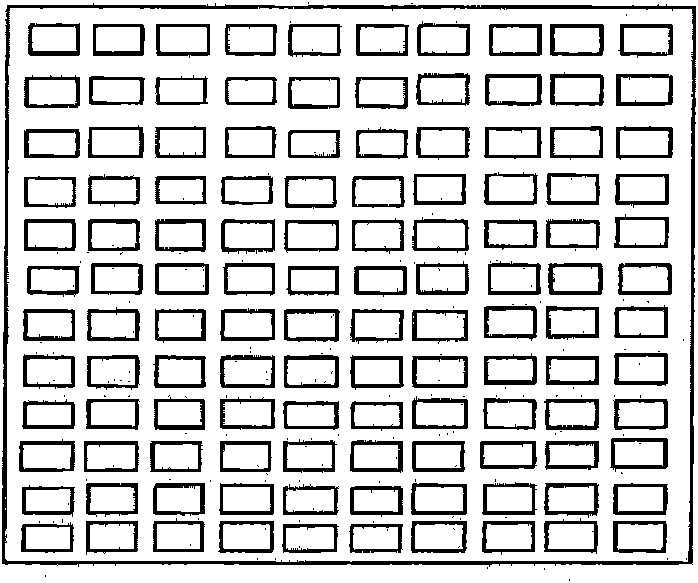

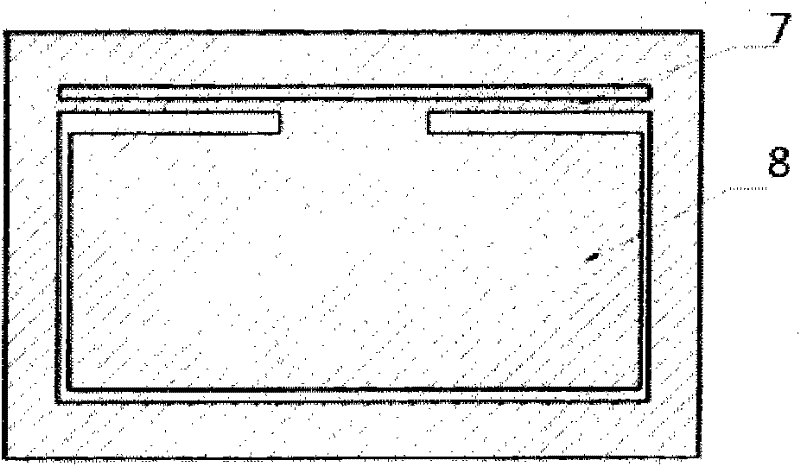

[0034] 3. On the photoresist on the upper surface after pre-curing prepared in step 2, use a rectangular hole array as a mask, and expose it under an exposure machine, wherein the overall size of the mask is as large as that of the stainless steel substrate, and the size of the rectangular hole is 2mm×1mm, spacing 0.2mm;

[0035] 4. Soak the substrate in the photoresist developer for 5 m...

Embodiment 2

[0049] 1. Select a stainless steel substrate with a size of 50mm×50mm×0.6mm, soak it in dilute nitric acid for 15 minutes to remove the oxide on the surface of the stainless steel sheet, then soak it in concentrated alkali solution for 20 minutes to remove the oil on the surface of the stainless steel sheet, and finally use it Drying after washing with ionized water;

[0050] 2. On the upper and lower surfaces of the stainless steel substrate processed in step 1, prepare a layer of positive SU-8 photoresist by spraying method, and pre-cure the photoresist for 30 minutes at 85 degrees Celsius;

[0051] 3. On the photoresist on the upper surface after pre-curing prepared in step 2, use a rectangular hole array as a mask, and expose it under an exposure machine, wherein the overall size of the mask is as large as that of the stainless steel substrate, and the size of the rectangular hole is 1.6mm×0.7mm, spacing 0.2mm;

[0052] 4. Soak the substrate in the photoresist developer f...

Embodiment 3

[0066] 1. Select a stainless steel substrate with a size of 45mm×45mm×0.7mm, soak it in dilute nitric acid for 15 minutes to remove the oxide on the surface of the stainless steel sheet, then soak it in concentrated alkali solution for 20 minutes to remove the oil on the surface of the stainless steel sheet, and finally use it Drying after washing with ionized water;

[0067] 2. On the upper and lower surfaces of the stainless steel substrate processed in step 1, prepare a layer of positive SU-8 photoresist by spraying method, and pre-cure the photoresist for 30 minutes at 85 degrees Celsius;

[0068] 3. On the photoresist on the upper surface after pre-curing prepared in step 2, use a rectangular hole array as a mask, and expose it under an exposure machine, wherein the overall size of the mask is as large as that of the stainless steel substrate, and the size of the rectangular hole is 1.8mm×0.8mm, spacing 0.2mm;

[0069] 4. Soak the substrate in the photoresist developer f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com