Packaging structure of flexible Mini LED and preparation method of packaging structure

A packaging structure, LED lamp bead technology, applied in electrical components, electric solid devices, circuits, etc., can solve the problems of LED lamp beads being easily corroded by water vapor, poor silicone barrier ability, affecting display effects, etc., to achieve high flexible display effect, relieve stress concentration, reduce the effect of shadow area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

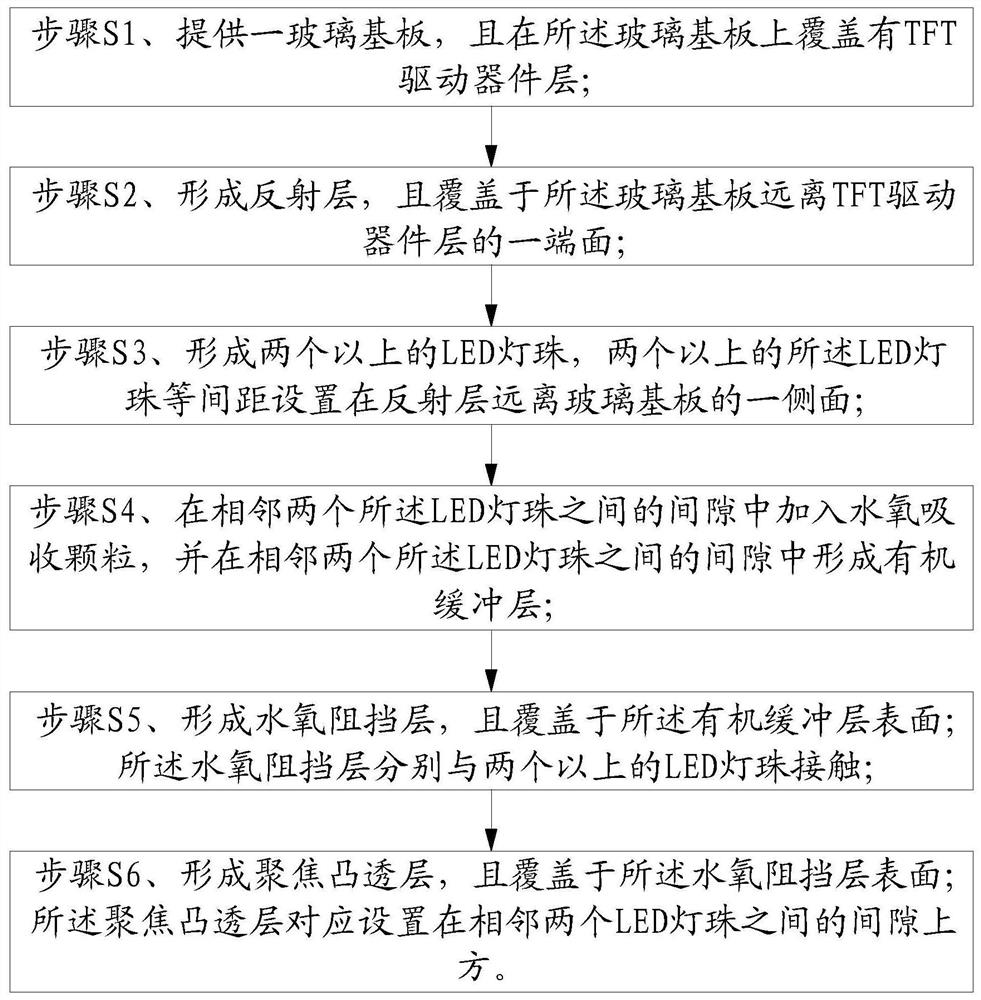

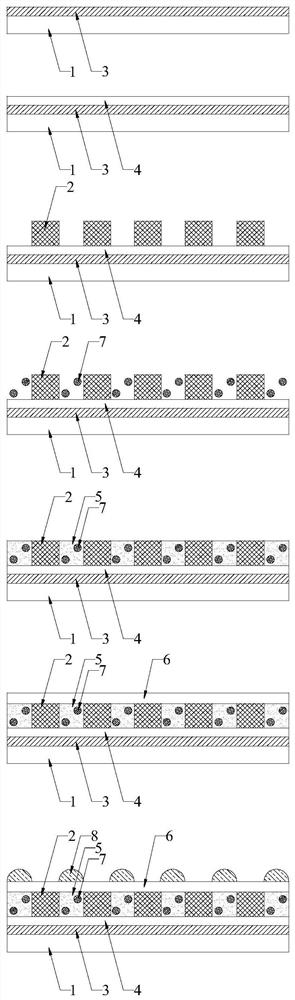

[0038] A method for preparing a packaging structure of a flexible Mini LED, comprising the following steps:

[0039] Step S1, providing a glass substrate, and a TFT driving device layer is covered on the glass substrate;

[0040] Step S2, forming a reflective layer and covering an end surface of the glass substrate away from the TFT driving device layer;

[0041] Step S3, forming more than two LED lamp beads, and the more than two LED lamp beads are arranged at equal intervals on the side of the reflective layer away from the glass substrate;

[0042]Step S4, adding water and oxygen absorbing particles in the gap between two adjacent LED lamp beads, and forming an organic buffer layer in the gap between two adjacent LED lamp beads;

[0043] Step S5, forming a water-oxygen barrier layer and covering the surface of the organic buffer layer; the water-oxygen barrier layer is respectively in contact with two or more LED lamp beads;

[0044] Step S6 , forming a focusing convex la...

Embodiment 1

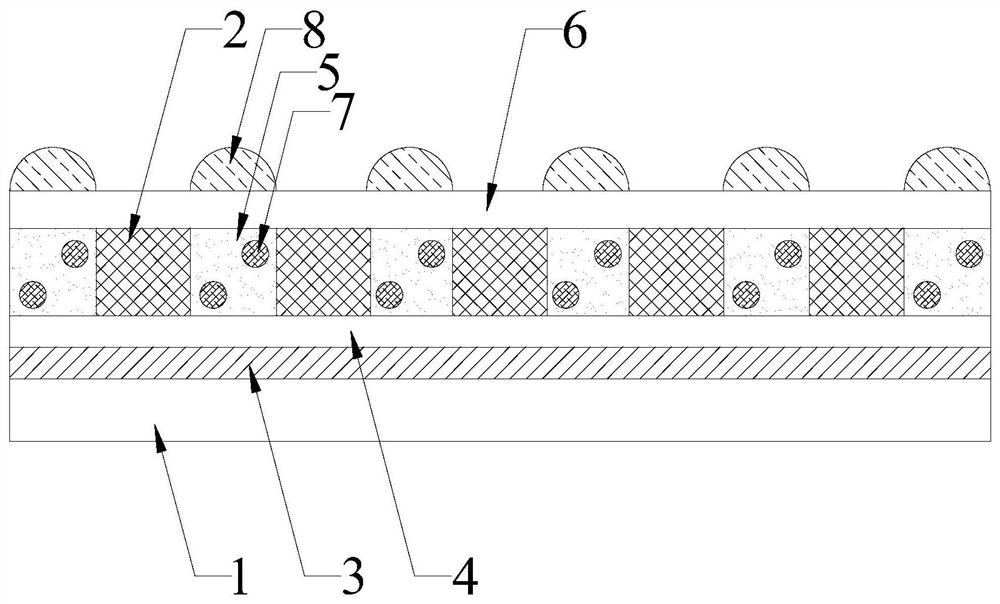

[0055] Please refer to figure 1 , Embodiment 1 of the present invention is:

[0056] A flexible Mini LED packaging structure, including a TFT driving device layer 1 and more than two LED lamp beads 2, on one end surface of the TFT driving device layer 1, a glass substrate 3, a reflective layer 4, an organic The buffer layer 5 and the water-oxygen barrier layer 6, more than two LED lamp beads 2 are embedded in the organic buffer layer 5 at equal intervals, one end surface of the LED lamp beads 2 is in contact with the water-oxygen barrier layer 6, and the One end face of the LED lamp bead 2 opposite to the other end face is in contact with the reflective layer 4, and water and oxygen absorbing particles 7 are arranged between two adjacent LED lamp beads 2, and the water and oxygen absorbing particles 7 are embedded in organic In the buffer layer 5, more than two focusing convex layers 8 are provided on the end surface of the water and oxygen barrier layer 6 away from the organ...

Embodiment 2

[0061] Please refer to figure 2 and image 3 , the second embodiment of the present invention is:

[0062] Please refer to figure 2 , a method for preparing a packaging structure of a flexible Mini LED, comprising the following steps:

[0063] Step S1, providing a glass substrate 3, and the TFT driving device layer 1 is covered on the glass substrate 3;

[0064] Step S2, forming a reflective layer 4, and covering an end surface of the glass substrate 3 away from the TFT driving device layer 1;

[0065] Step S3, forming more than two LED lamp beads 2, and more than two LED lamp beads 2 are arranged at equal intervals on the side of the reflective layer 4 away from the glass substrate 3;

[0066] Step S4, adding water and oxygen absorbing particles 7 in the gap between two adjacent LED lamp beads 2, and forming an organic buffer layer 5 in the gap between two adjacent LED lamp beads 2;

[0067] Step S5, forming a water-oxygen barrier layer 6 and covering the surface of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com