High-speed special submerged motor for engineering ship

A technology of submersible electricity and engineering ships, applied in the direction of electric components, electrical components, electromechanical devices, etc., can solve the problems of low sealing reliability, motor torque pulsation, no sealing measures, etc., and achieve safe and reliable operation and operation performance Stabilization and anti-condensation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

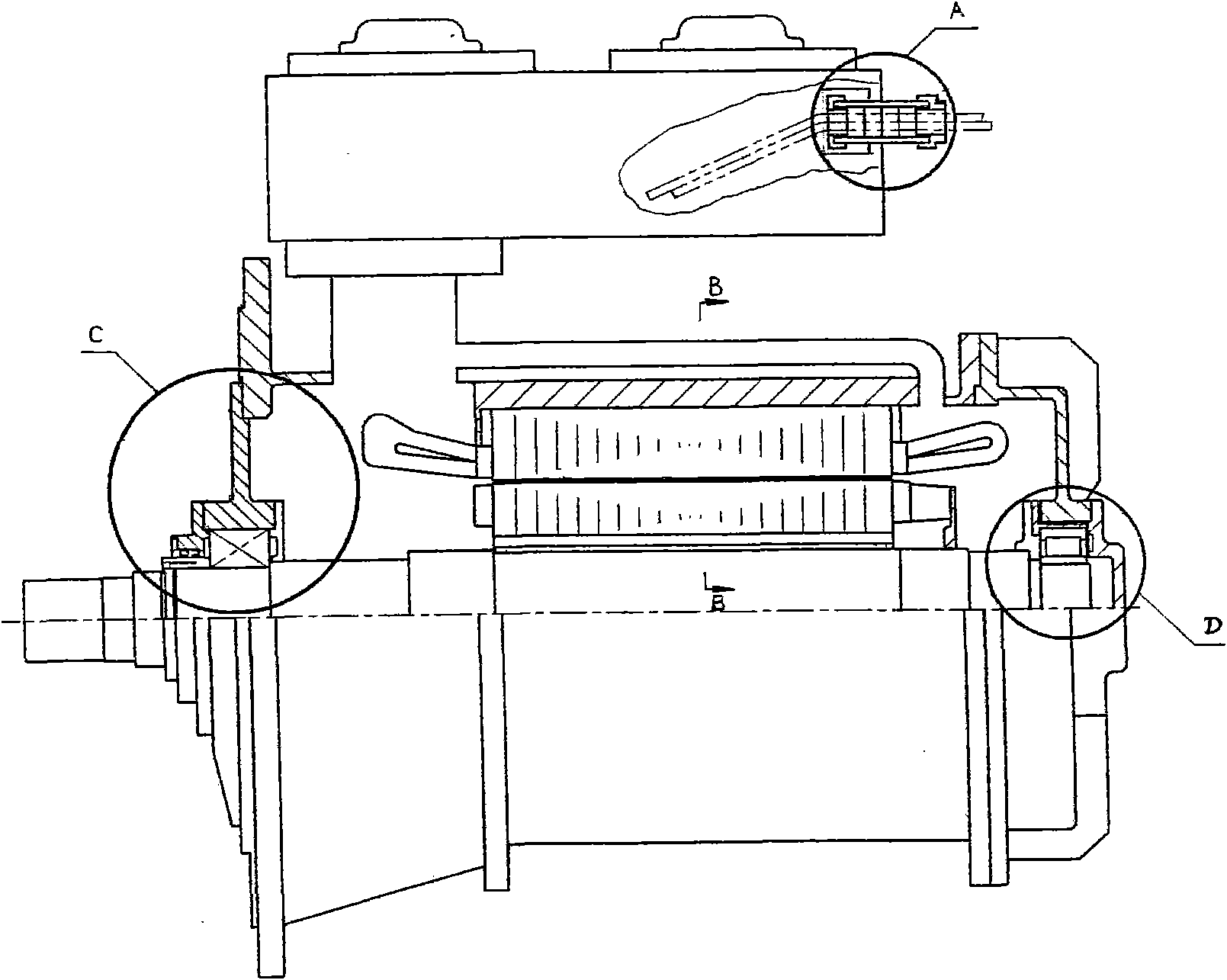

[0031] now attached Figure 1-9 An embodiment of the present invention will be described in detail. Embodiment is the further implementation of the content of the present invention, but the scope of protection of the present invention is by no means limited to the embodiment.

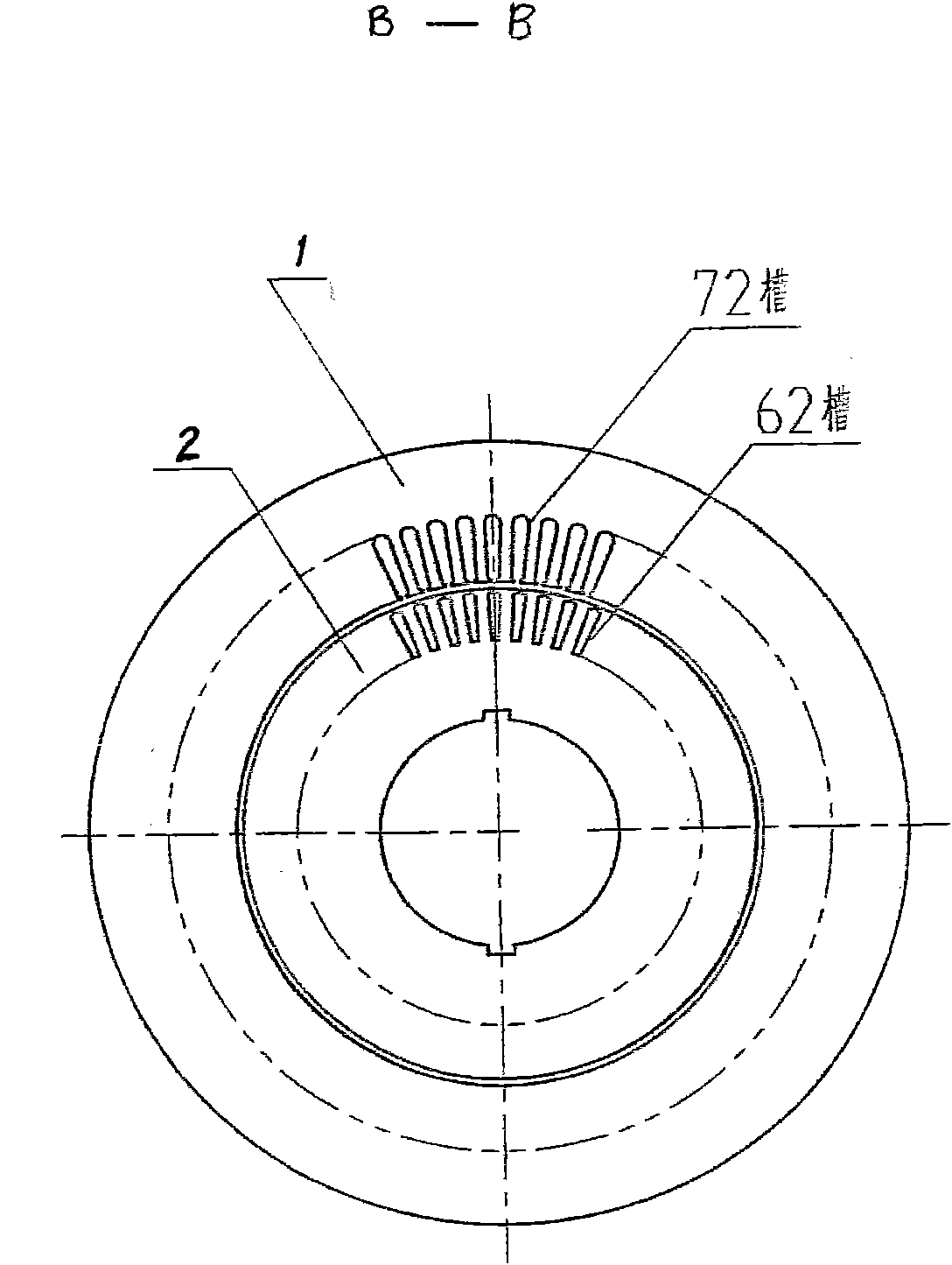

[0032] A high-speed special submersible motor for engineering ships, including a stator, a rotor, a dynamic sealing device, a shaft current prevention structure, and lead cables. It is wide at the top and narrow at the bottom, the number of slots of the stator punch [1] is greater than the number of slots of the rotor punch [2]; the end of the submersible motor is provided with a dynamic sealing device, which includes the stator [3], the rotating shaft [12], the shaft sleeve [10] is fixed on the rotating shaft [12], the seal seat [5] is sealed with the shaft sleeve [10], the seal gland [7] presses the skeleton seal [8] into the groove of the seal seat [5], and the shaft sleeve There is sealing ring II...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com