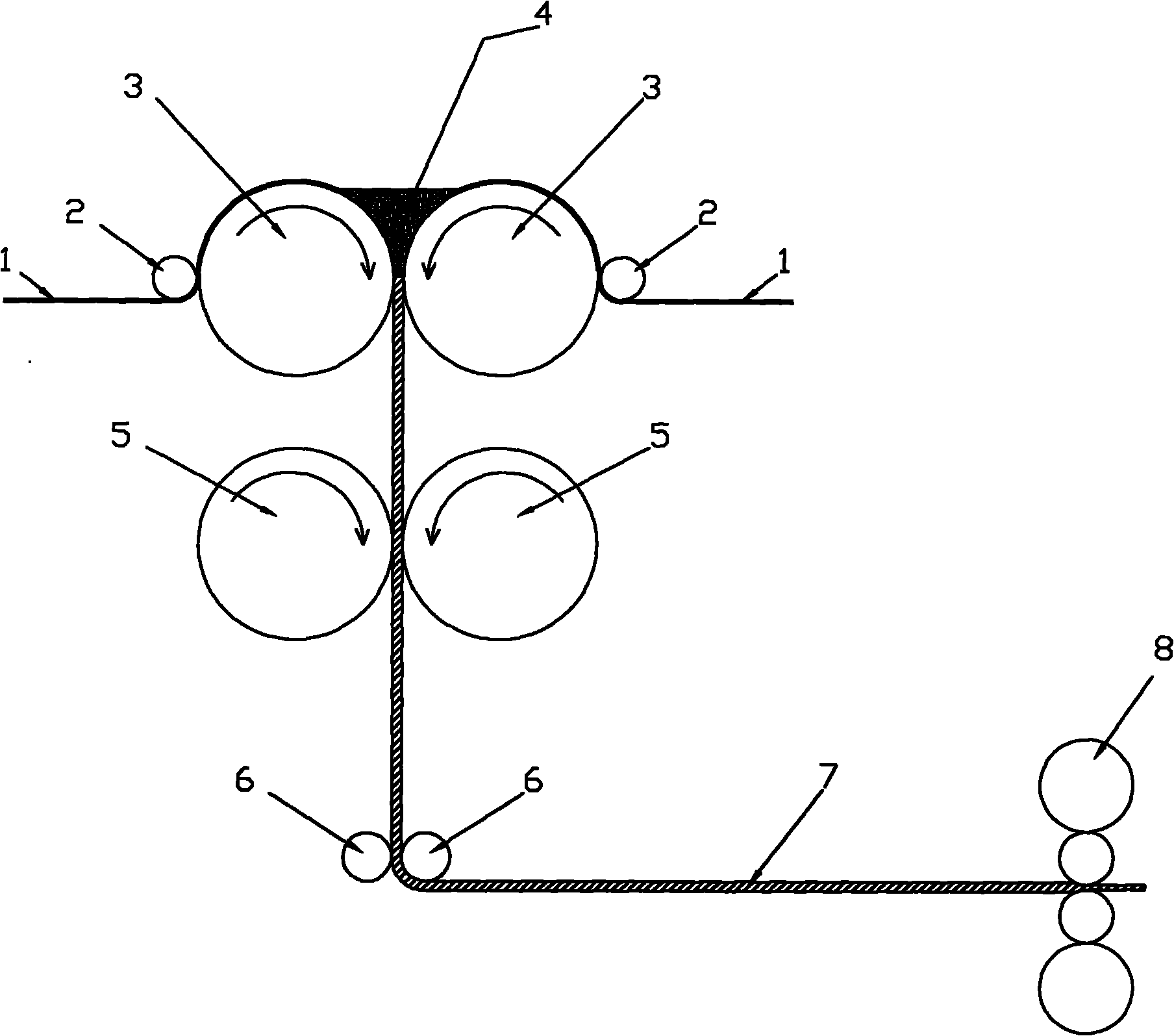

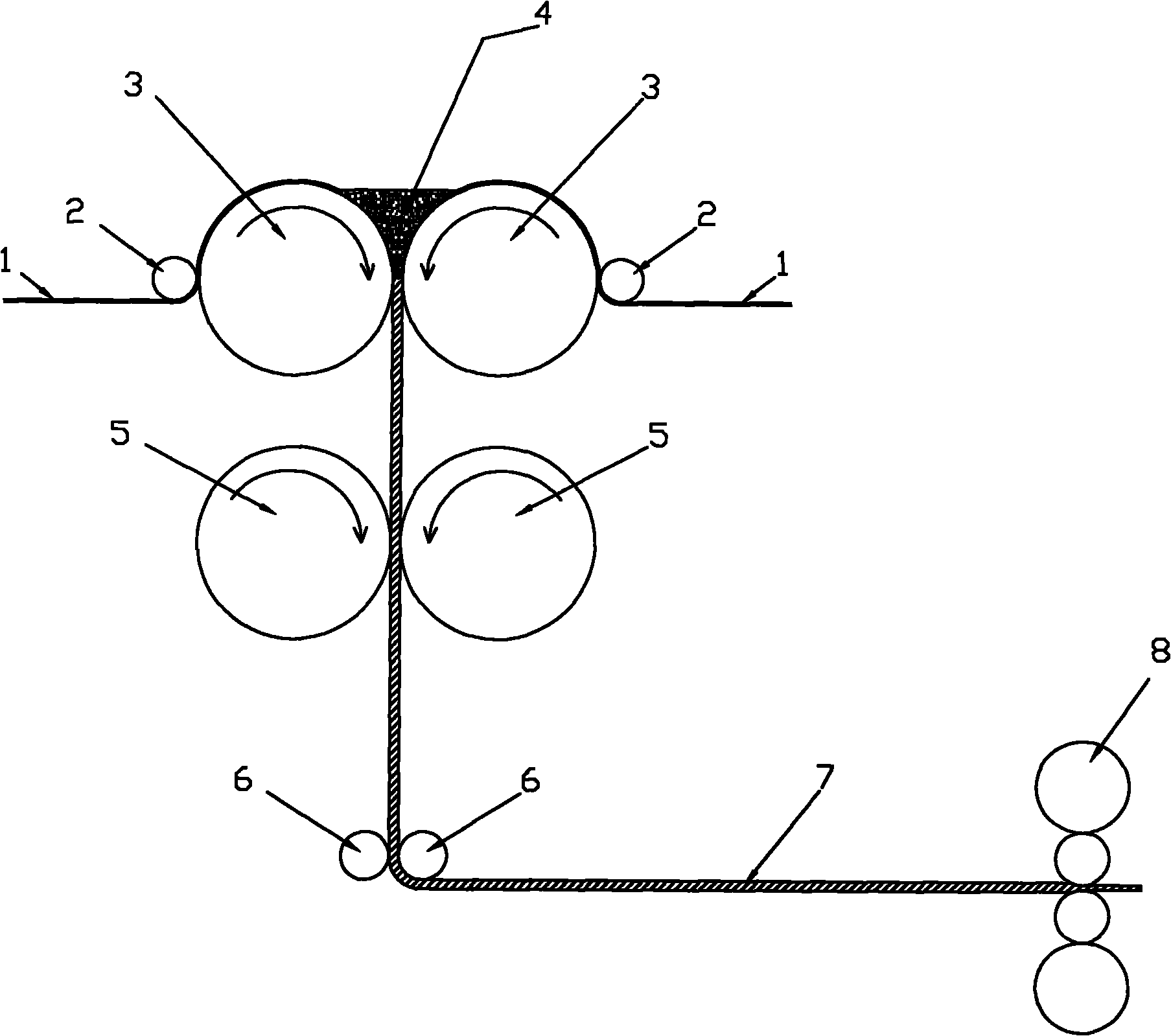

Twin-roller double-strip composite-structured thin strip continuous casting and rolling method

A composite structure, continuous casting and rolling technology, applied in metal rolling and other directions, can solve the problems of low surface grade, low steel strip continuous casting speed, and high thermal energy, and achieve easy control, strong production process adaptability, and surface quality. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039]In order to achieve industrial production of twin-roll twin-belt continuous casting, the laboratory simulates the method of making thin boxes from bimetallic plates. 2mm thick low-carbon steel plate is used to make a thin box with a width of 1 meter, a length of 100mm, and a thickness of 6mm. The outside of the thin box is cooled by a copper water tank. Use a 2mm nozzle to inject molten steel into the middle groove of the thin box, and then send it to the rolling mill for rolling after it is completely filled. The thickness of the final strip is 2mm. The cast strip has good surface quality and no internal defects, with an average grain size of 5 microns.

Embodiment 2

[0041] Process is the same as embodiment 1, is the thin box that is made of stainless steel. The thin strip finally obtained is a thin strip with a surface layer of stainless steel and a diffusion layer at the interface. The surface quality reaches the quality of hot-rolled stainless steel.

Embodiment 3

[0043] The process is the same as in Example 1, except that one side is a thin box made of 2mm stainless steel and the other side is a 3mm copper plate. The thin strip finally obtained is a thin strip whose surface layer is stainless steel on one side and copper on the other. The diffusion layer at the copper-steel interface is relatively large and well bonded. The surface quality reaches the quality of hot-rolled stainless steel, and the copper surface is oxidized to a certain extent, and the deformation is relatively large.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com