A kind of 590mpa grade automotive lightweight cold-rolled dual-phase steel and production method thereof

A dual-phase steel and lightweight technology, which is applied in the field of metallurgical plates, can solve the problems of difficult control of the surface quality of the steel strip, affect the welding performance of the steel strip, and reduce the pourability of smelting, and achieve high initial work hardening rate and good cold forming The effect of high initial work hardening rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

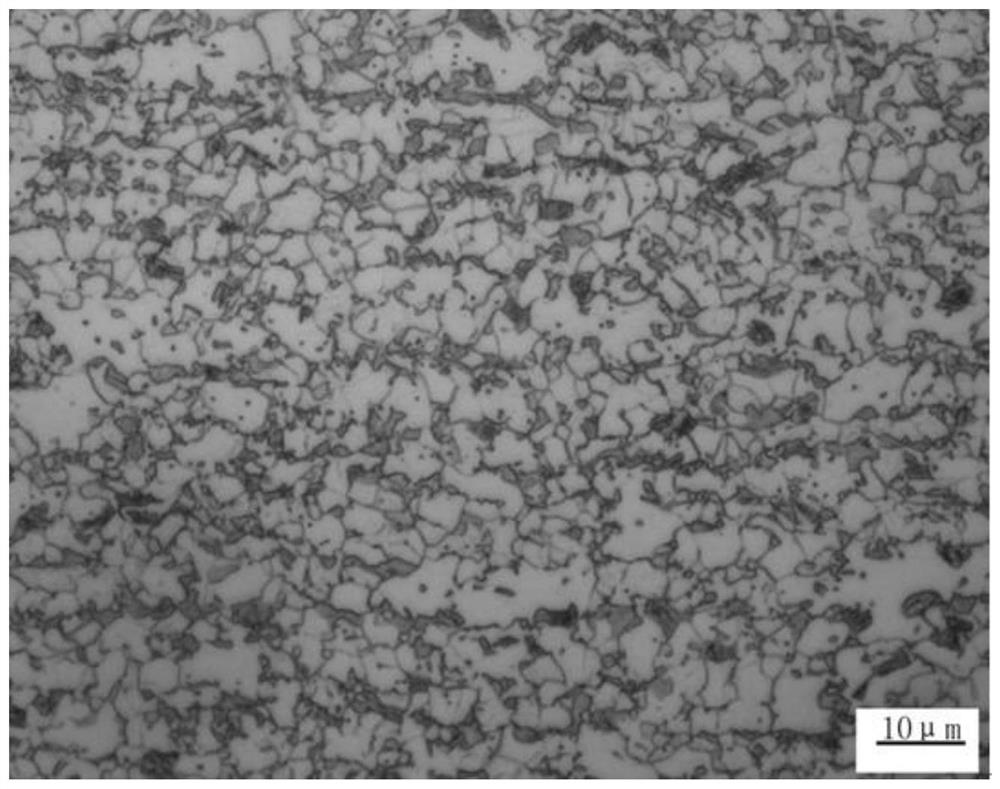

Image

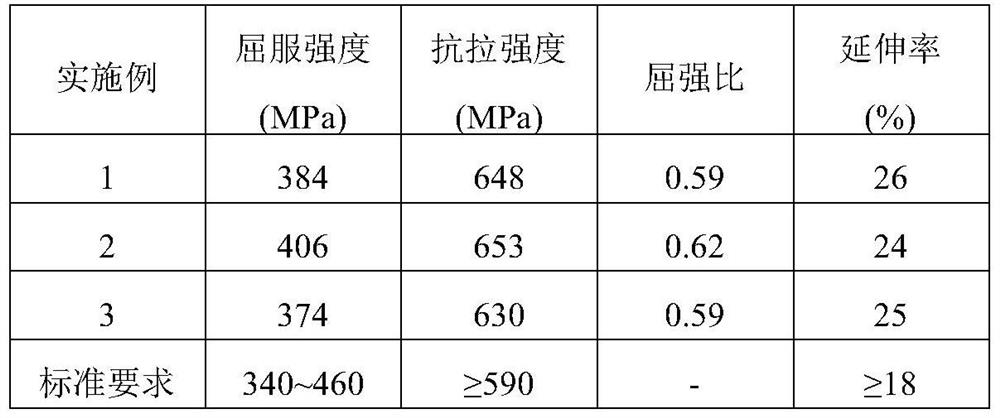

Examples

Embodiment 1

[0050] Embodiment 1, preparation of cold-rolled dual-phase steel

[0051] Desulfurization pretreatment is carried out on the molten iron, and the molten iron is decarburized and dephosphorized by top-bottom combined blowing converter smelting to obtain molten steel. The converter smelting process is blown with argon, and scrap steel is added to the converter, and the tapping temperature of the converter is 1640°C. Then, the molten steel after converter smelting is subjected to LF external refining, and the refining temperature is ≥1560°C. The LF external refining is subjected to temperature measurement and composition fine-tuning. The chemical composition of the LF external refining casting machine is shown in Table 1. The slab continuous casting superheat is 20°C, after which the slab is cleaned, slowly cooled, and the quality of the continuous casting slab is inspected to obtain the slab;

[0052] The heating temperature of the slab is 1230° C., and the heating time is 225 m...

Embodiment 2

[0056] Desulfurization pretreatment is carried out on the molten iron, and the molten iron is decarburized and dephosphorized by top-bottom combined blowing converter smelting to obtain molten steel. The converter smelting process is blown with argon, and scrap steel is added to the converter, and the tapping temperature of the converter is 1632°C. Then, the molten steel after converter smelting is subjected to LF external refining, and the refining temperature is ≥1560°C. The LF external refining is subjected to temperature measurement and composition fine-tuning. The chemical composition of the LF external refining casting machine is shown in Table 1. The slab continuous casting superheat is 25°C, after which the slab is cleaned, slowly cooled, and the quality of the continuous casting slab is inspected to obtain the slab;

[0057] The heating temperature of the slab is 1230° C., and the heating time is 232 minutes. The heated slab is subjected to high-pressure water dephosph...

Embodiment 3

[0061] Desulfurization pretreatment is carried out on the molten iron, and the molten iron is decarburized and dephosphorized by top-bottom combined blowing converter smelting to obtain molten steel. The converter smelting process is blown with argon, and scrap steel is added to the converter, and the tapping temperature of the converter is 1650°C. Then, the molten steel after converter smelting is subjected to LF external refining, and the refining temperature is ≥1560°C. The LF external refining is subjected to temperature measurement and composition fine-tuning. The chemical composition of the LF external refining casting machine is shown in Table 1. The superheat degree of the slab continuous casting is 30°C, after which the slab is cleaned, slowly cooled, and the quality of the continuous casting slab is inspected to obtain the slab;

[0062] The heating temperature of the slab is 1220° C., and the heating time is 235 minutes. The heated slab is subjected to high-pressure ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| yield ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com