Device for preparing ultra-fine grain copper-aluminum wire with variable passage and preparation method

A preparation device and ultra-fine grain technology, applied in the direction of wire drawing dies, etc., can solve the problems of difficult to meet the mass production of microplastic forming, complex process, high processing cost, etc., and achieve good consistency, simple process and good deformation effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] This embodiment is a kind of specification for forming copper wire diameter It is a variable channel device and a drawing method with a grain size of 4mm and a grain size of 50-100nm.

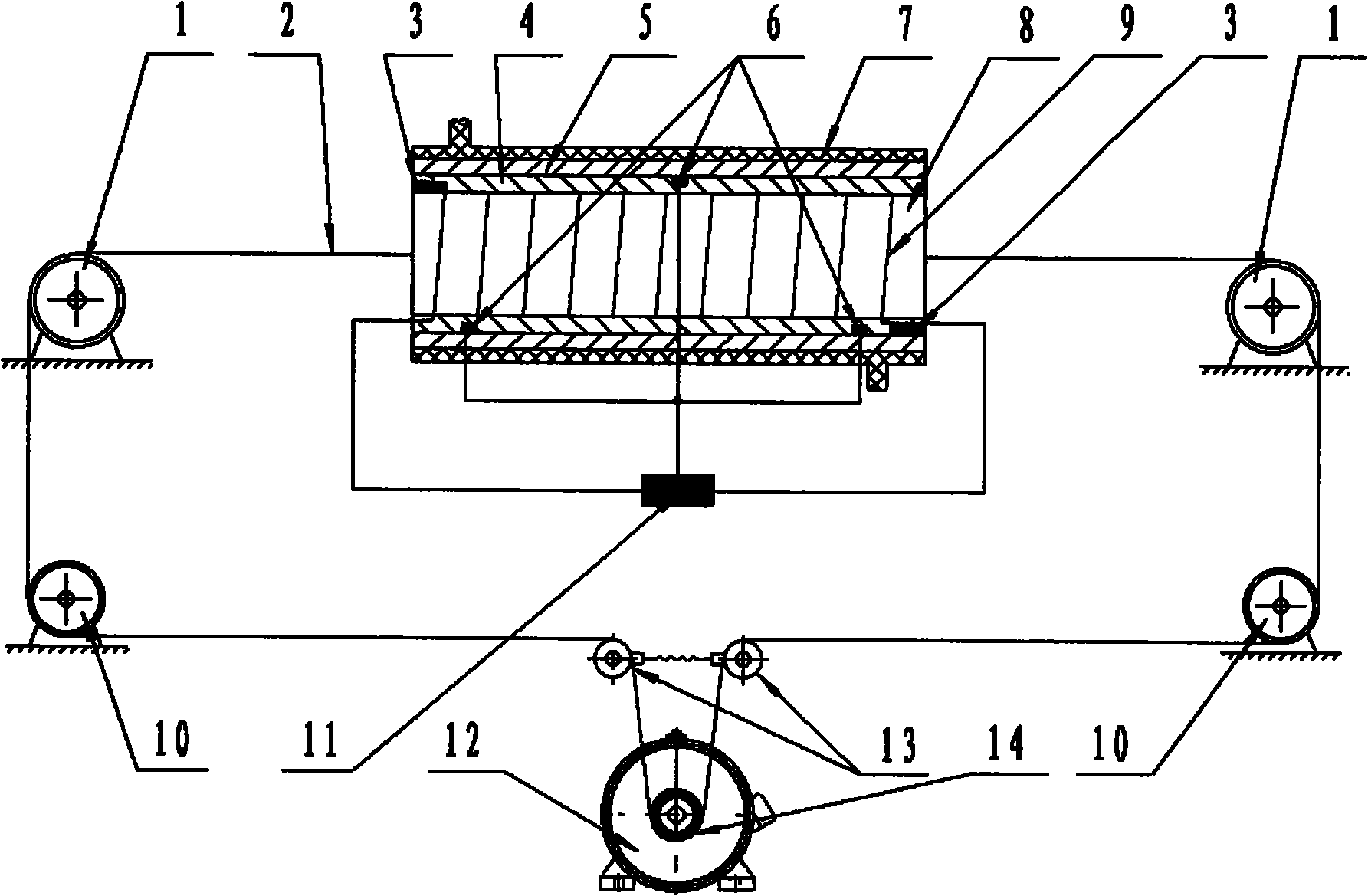

[0028] The channel changing device proposed in this embodiment includes a mold, a guide wheel 1, a reversing wheel 10, a heating and cooling assembly and a drawing assembly.

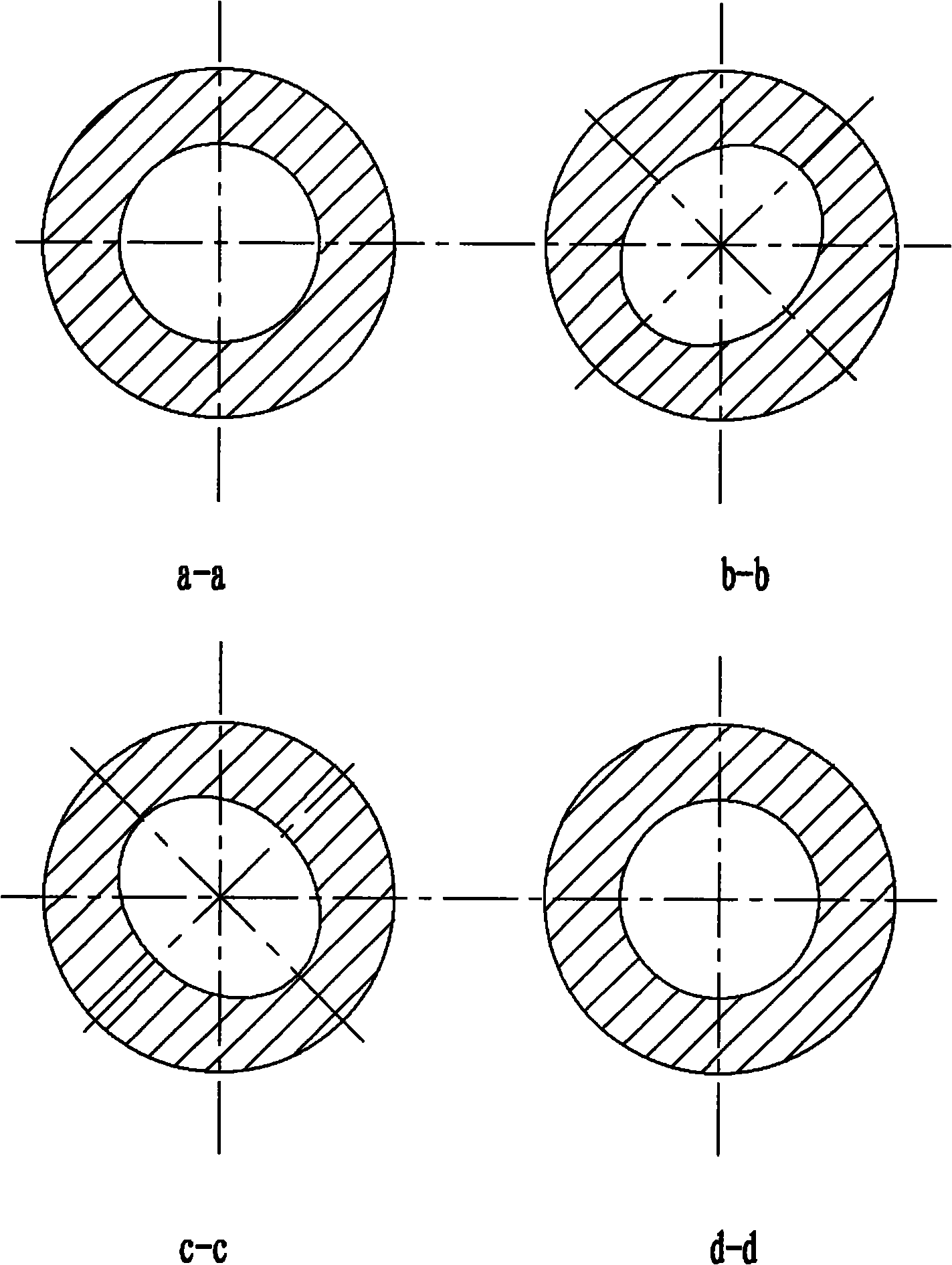

[0029] The mold is composed of a mold core 8 and a mold sleeve 4; the inner diameter of the mold sleeve 4 is equal to the outer diameter of the mold core 8, which is 7mm; the mold core 8 is a hollow cylinder divided into two parts, and its inner cavity is a circular section A cavity with a smooth transitional cross-sectional shape that changes from an elliptical cross-section to a circular cross-section; the mold core 8 is fixed in the mold casing 4 .

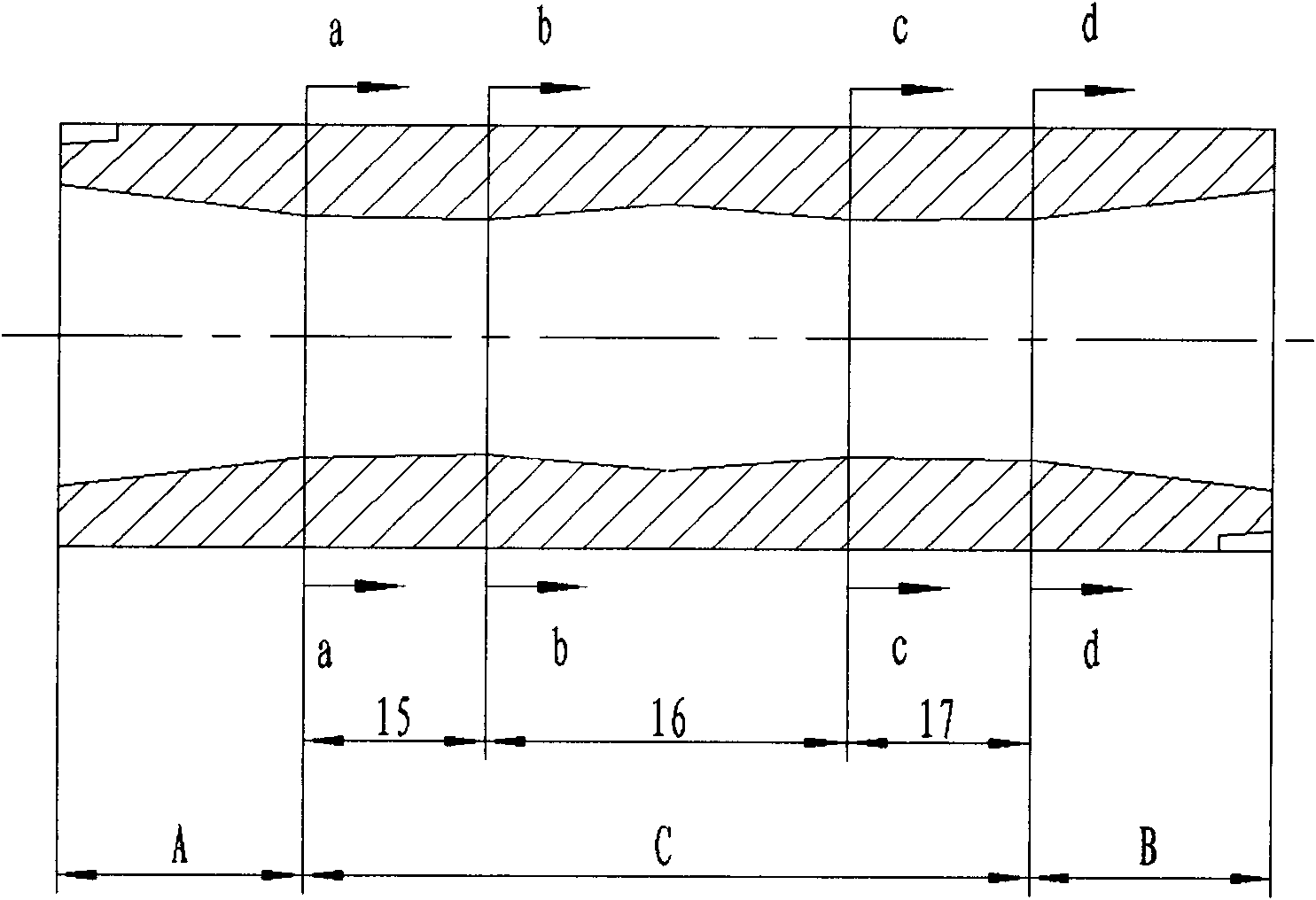

[0030] The cavity of the mold core 8 is divided into a first guide section A, a deformation section C and a second guide section B.

[0031] The first guide sect...

Embodiment 2

[0047] This embodiment is a kind of specification for forming aluminum wire rod diameter A variable channel drawing device and method with a grain size of 6mm and a grain size of 80-150nm.

[0048] The drawing device proposed in this embodiment includes a mold, a guide wheel 1, a reversing wheel 10, a heating and cooling assembly and a drawing assembly.

[0049] The mold is composed of a mold core 8 and a mold sleeve 4; the inner diameter of the mold sleeve 4 is equal to the outer diameter of the mold core 8, both of which are 10mm; the mold core 8 is a hollow cylinder divided into two lobes, and its inner cavity is a circular section A cavity with a smooth transitional cross-sectional shape that changes from an elliptical cross-section to a circular cross-section; the mold core 8 is fixed in the mold casing 4 .

[0050] The cavity of the mold core 8 is divided into a first guide section A, a deformation section C and a second guide section B.

[0051] The first guide secti...

Embodiment 3

[0066] This embodiment is a kind of specification for forming aluminum wire rod diameter The variable channel drawing device and method have a grain size of 8mm and 30-80nm.

[0067] The drawing device proposed in this embodiment includes a mold, a guide wheel 1, a reversing wheel 10, a heating and cooling assembly and a drawing assembly.

[0068] The mold is composed of a mold core 8 and a mold sleeve 4; the inner diameter of the mold sleeve 4 is equal to the outer diameter of the mold core 8, both of which are 15mm; the mold core 8 is a hollow cylinder divided into two parts, and its inner cavity is a circular section A cavity with a smooth transitional cross-sectional shape that changes from an elliptical cross-section to a circular cross-section; the mold core 8 is fixed in the mold casing 4 .

[0069] The cavity of the mold core 8 is divided into a first guide section A, a deformation section C and a second guide section B.

[0070] The first guide section A of the mol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com