Heavy hydrocarbon hydrogenation combined process

A combined process and heavy hydrocarbon technology, which is applied in the fields of hydrotreating process, petroleum industry, and hydrocarbon oil treatment, can solve the problems of no specific combination, etc., and achieve the effects of increasing conversion rate, slowing down catalyst carbon deposition, and improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

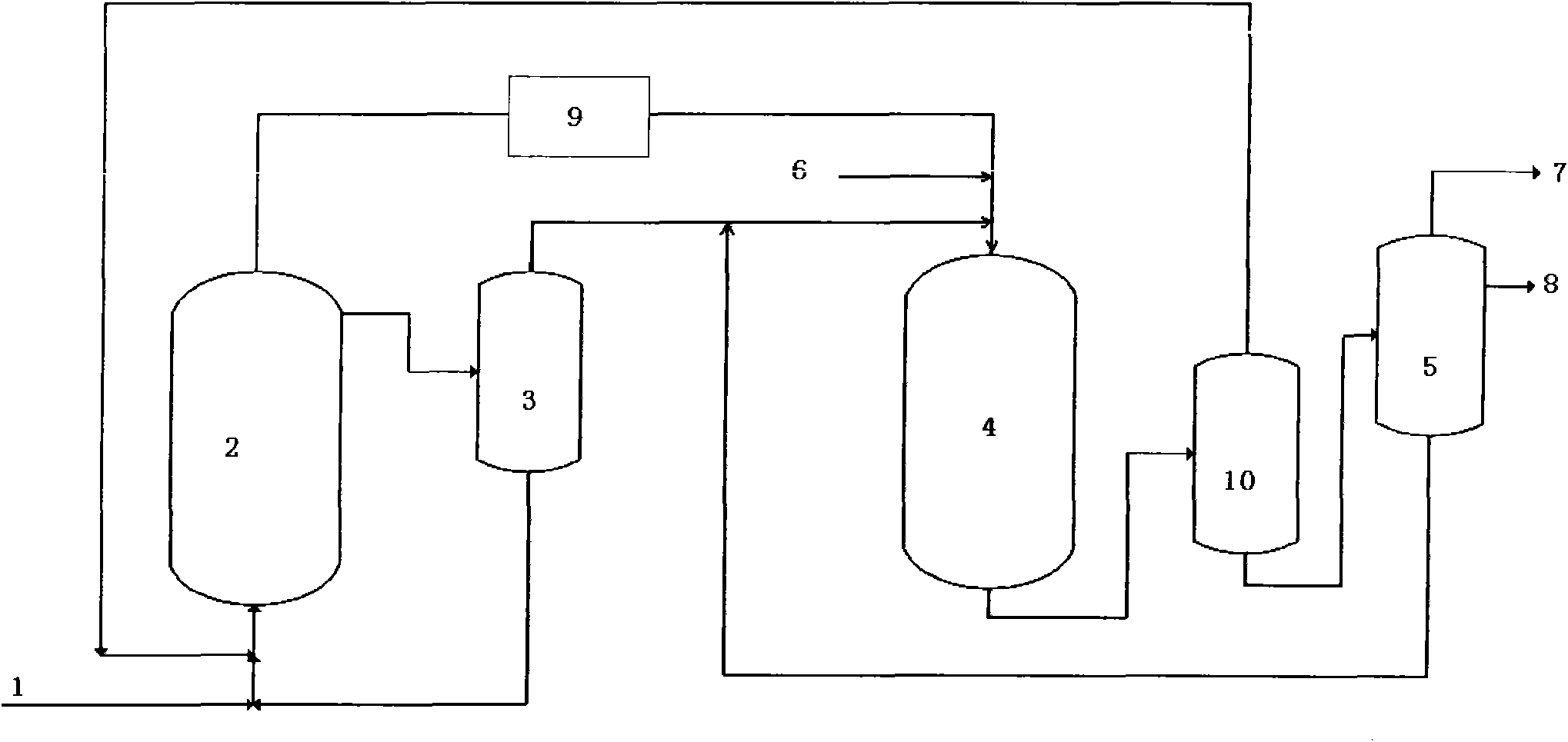

[0028] This example is an embodiment of the heavy hydrocarbon hydrogenation combined process, and the operation flow is according to figure 1 shown. The ebullating bed and the fixed bed are operated at the same pressure level, and the reaction pressure of the fixed bed is slightly higher than that of the ebullating bed. The gas phase of the ebullating bed reaction effluent is dehydrogenated and then pressurized by a hydrogen cycle compressor to enter the fixed bed, and the fixed bed reaction effluent The gas phase after gas-liquid separation directly enters the ebullating bed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com