Steel-top aluminium-skirt piston ring groove induction strengthened self-tempering preventor

A piston ring groove and self-tempering technology, which is applied in the direction of quenching devices, furnace types, furnaces, etc., can solve the problems of reduced surface hardness of the first ring groove, weakened induction strengthening effect, poor quality stability, etc., to prevent self-tempering Phenomenon, improve wear resistance, improve the effect of pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

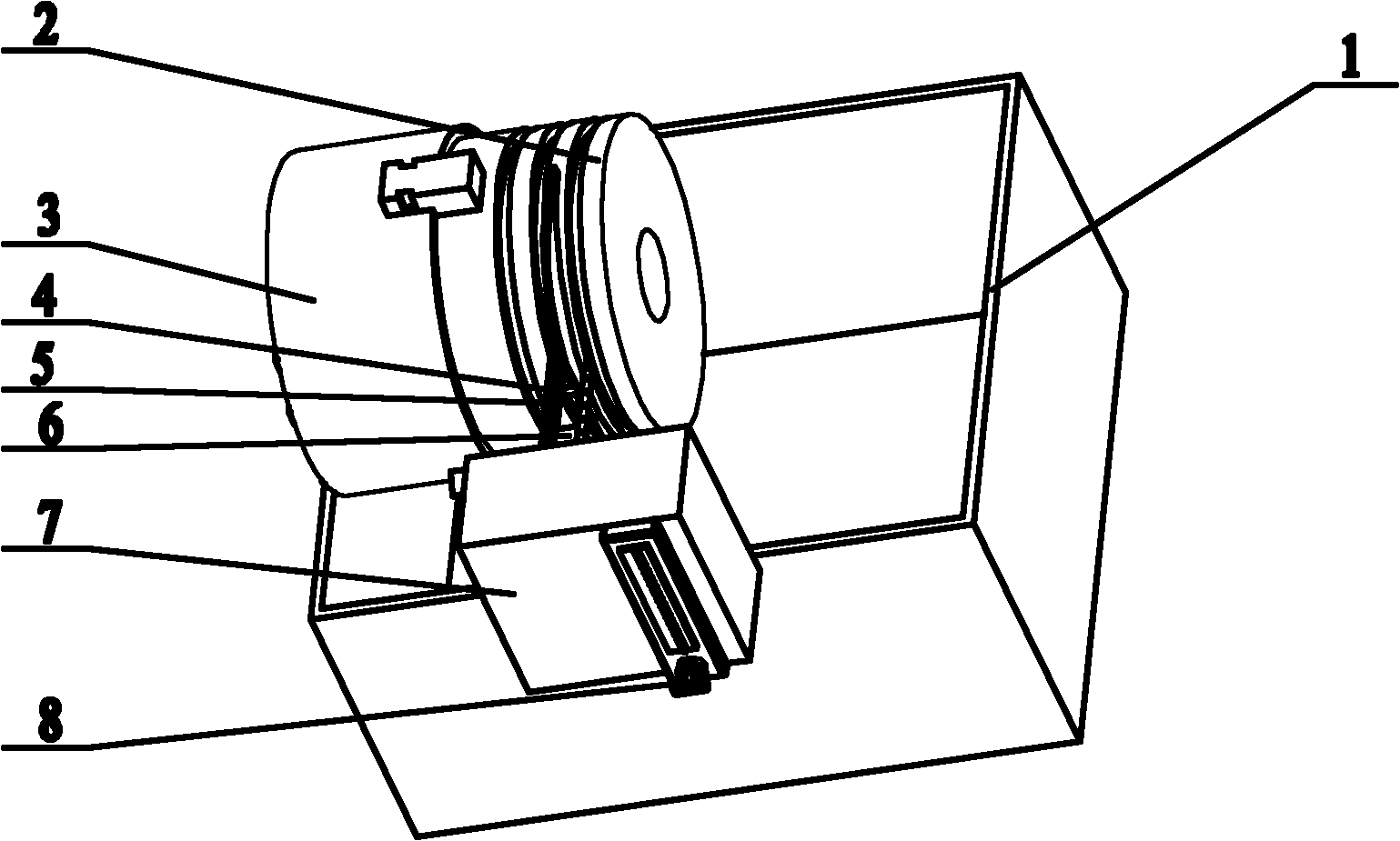

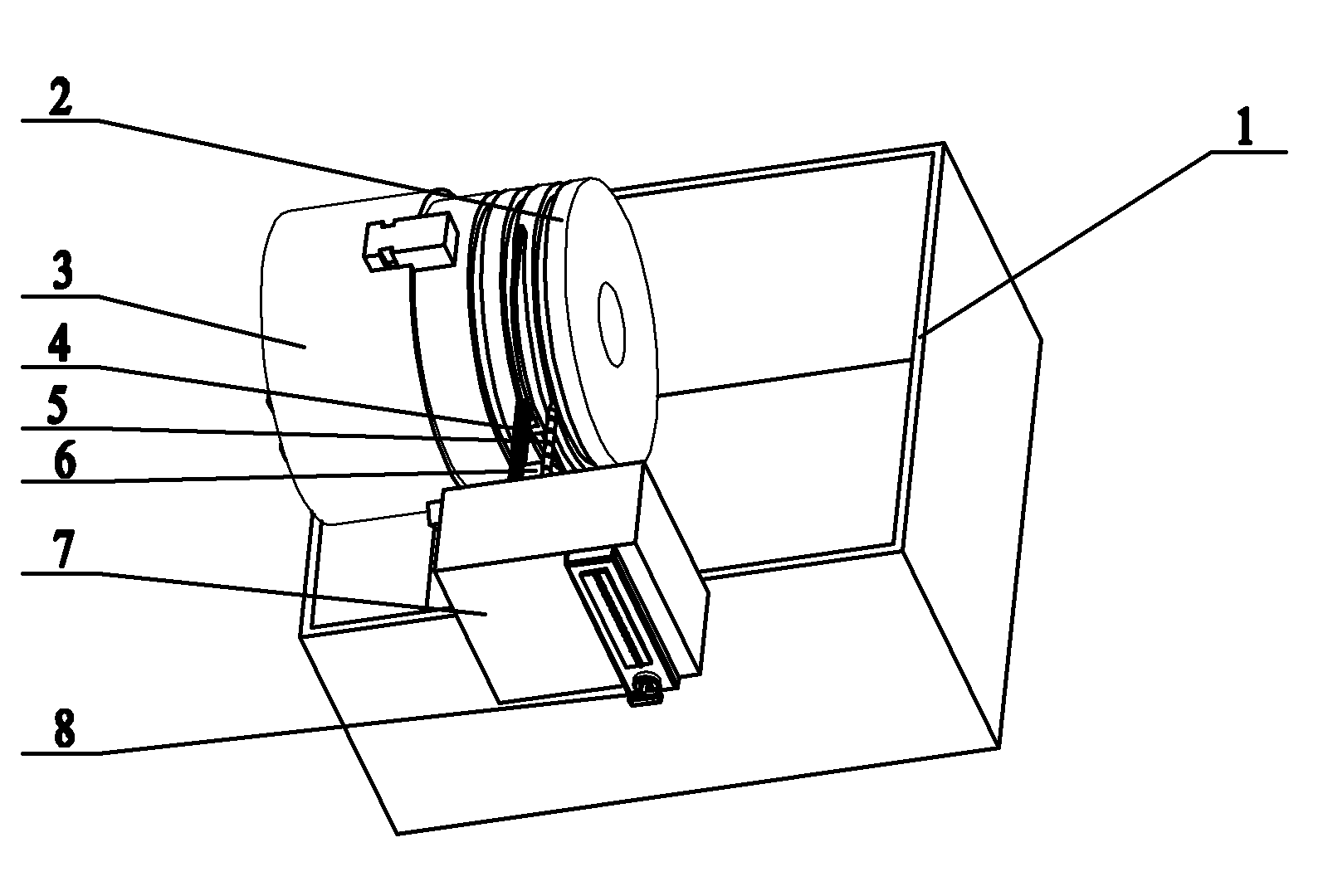

[0008] The present invention will be further described below in conjunction with specific drawings and embodiments.

[0009] As shown in the figure, the present invention is mainly composed of a quenching water tank 1, a chuck 3, an inductor 4, an isolation plate 5, a spray head 6, a connection box 7, a flow meter 8 and other components.

[0010] The steel top aluminum skirt piston ring groove induction strengthening anti-self-tempering device includes a chuck 3 fixedly installed on the quenching water tank 1, and a connecting joint is slidably installed on the wall plate of the quenching water tank 1 parallel to the axis of the chuck 3 Box 7, the sensor 4, the isolation plate 5 and the sprinkler head 6 are fixedly installed on the connection box 7, the sensor 4 and the sprinkler head 6 are separated by the isolation plate 5, and a flow meter is installed on the connection box 7 8. The flow meter 8 is matched with the shower head 6.

[0011] The shower head 6 is arranged hori...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com