Process for replacing adhesive tape for adhesive tape transporter of coal mine main shaft loading chamber

A belt conveyor and belt technology, applied in underground transportation, transportation and packaging, earth drilling and mining, etc., can solve the problems of material input waste, high construction labor intensity, and long time consumption, so as to improve construction safety factor and reduce construction labor Strength and the effect of shortening the construction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

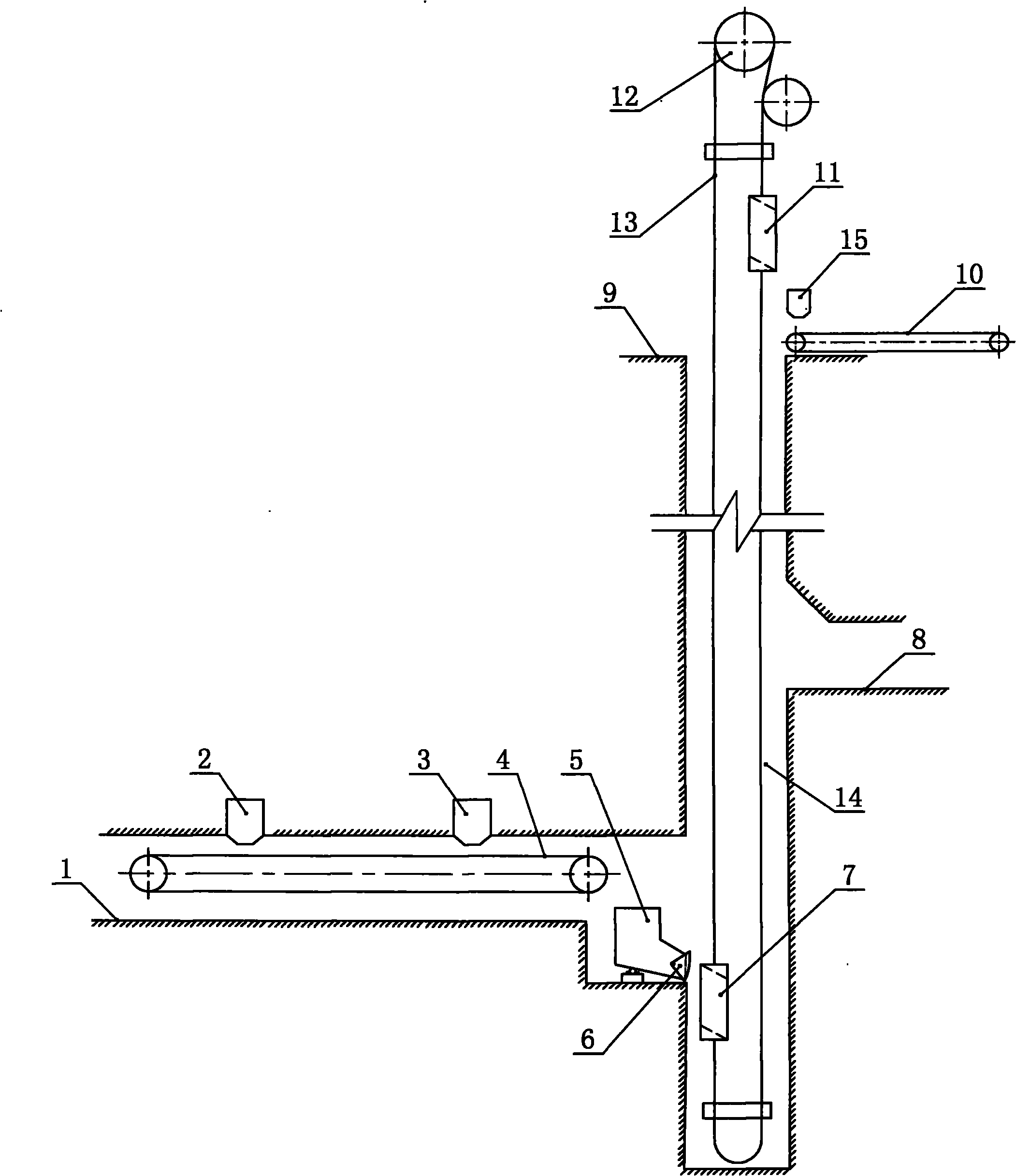

[0032] The present invention as figure 1 as shown, figure 1It is the coal mine loading lifting system diagram of the present invention.

[0033] exist figure 1 Among them, 1. The main shaft of the coal mine is loaded with caverns; 2. 3. The centralized coal bunker for storing coal underground in the coal mine, and the coal is lowered to the loading belt conveyor through the coal feeder; Two belt conveyors, one belt conveyor is installed in some mines, and the coal feeding of two quantitative buckets is realized by using the flap; 5. The main shaft of the coal mine is loaded with quantitative buckets in the cavity, and it has its own weighing device, which is used to measure the one-time lifting of the skip After reaching the lifting weight of the skip, a signal is sent to stop the operation of the belt conveyor. There are two quantitative buckets installed with fan-shaped gates. After opening, carbon is loaded into the skip in place; 6. The quantitative bucket fan-shaped gat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com