Machine tool moving part realizing method capable of meeting high-acceleration requirement

A moving parts, high-acceleration technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problems such as the lack of high-acceleration moving parts technology, shorten the development cycle, ensure product quality, and reduce development costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

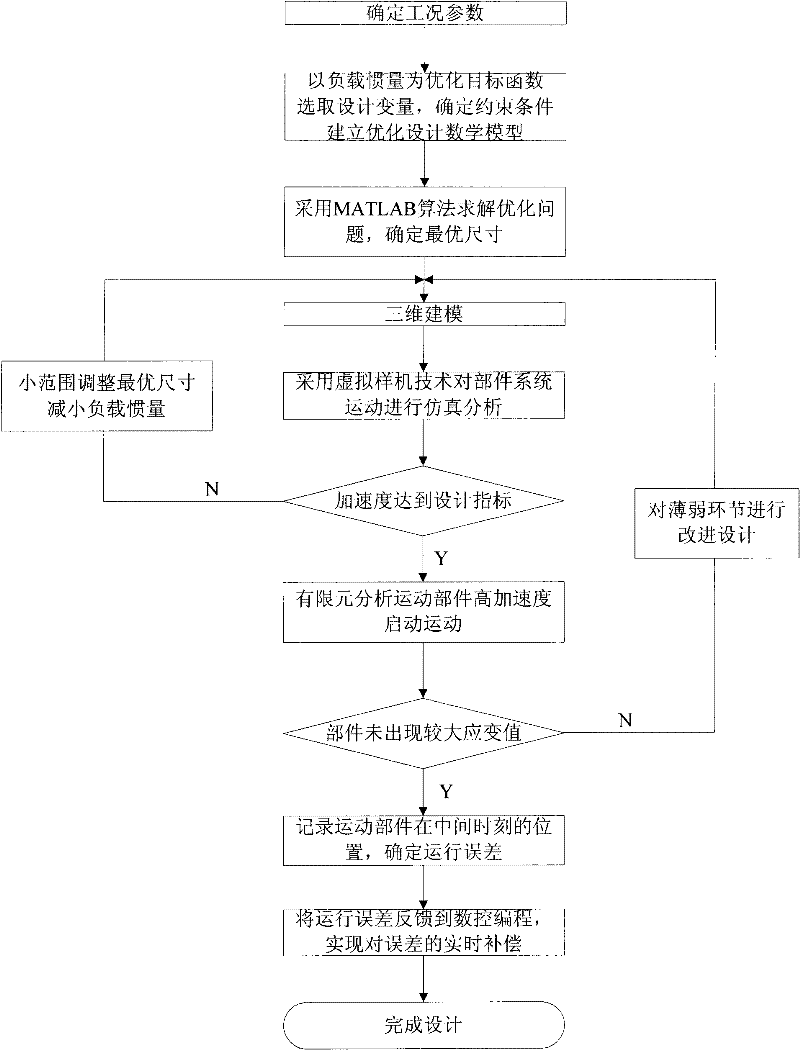

[0023] The steps of the present invention include: (1) determining working condition parameters such as density, modulus of elasticity, coefficient of friction, range of basic external dimensions, and selected motor power of moving parts of the machine tool; (2) taking the load inertia of the parts as the optimal design objective function , select the design variables, determine the constraints, and establish the mathematical model for its optimal design; (3) use the MATLAB algorithm to solve the optimization problem, and determine the optimal shape of the component; (4) establish the three-dimensional model of the component; (5) use the virtual Prototype technology, the system is simulated and analyzed by multi-rigid body dynamics software. Check whether the motion acceleration of the parts meets the requirements; (6) Analyze the high-acceleration starting motion of the moving parts through the finite element analysis software, and improve the design of the weak position of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com