System and method for compensating flow heat loss by utilizing additional heat generated through flow microbubble cavitation in focused ultrasound field

A technology of focused ultrasound and heat compensation, applied in the field of focused ultrasound, can solve the problems of increased pain, increased risk, high temperature, etc., and achieve the effect of enhancing reflection and improving the efficiency of ultrasonic heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

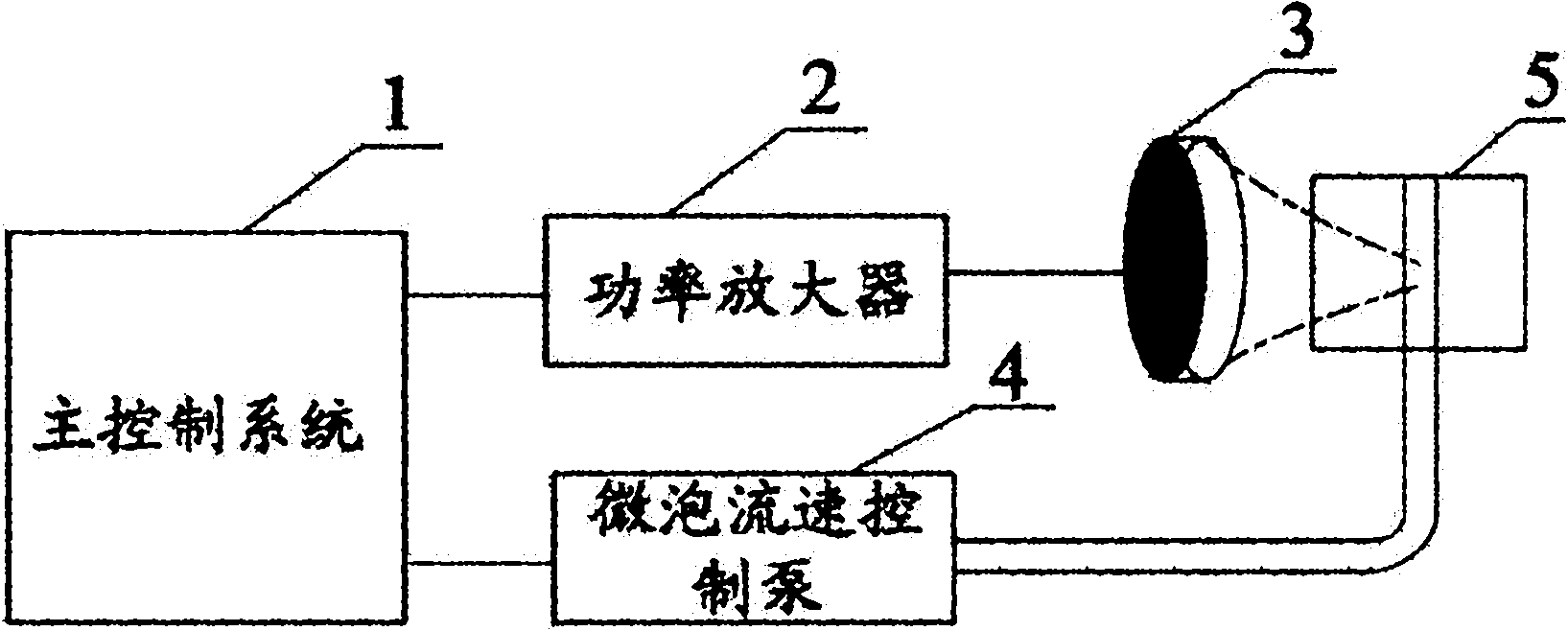

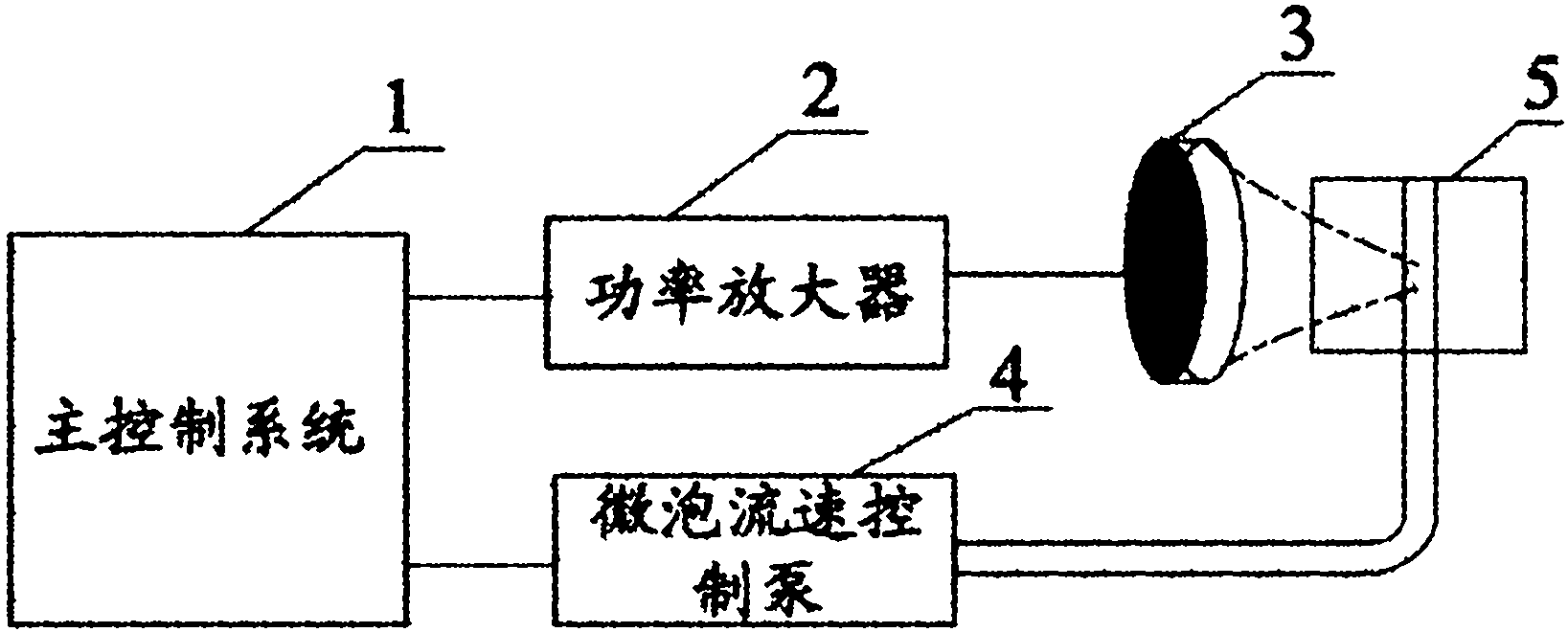

[0012] Embodiment 1: A system that uses flow microbubble cavitation to generate additional heat to compensate flow heat loss in a focused ultrasonic field, such as figure 1 shown. Including: main control system 1, power amplifier 2, focused ultrasonic transducer 3, microbubble flow rate control pump 4, sample 5.

[0013] System connection: the main control system 1 is connected to the power amplifier 2 and the microbubble flow rate control pump 4, the power amplifier 2 is connected to the focused ultrasound transducer 3, and the microbubble flow rate control pump 4 controls the flow rate of the microbubble solution in the simulated body.

[0014] The system consists of two parts, namely the focused ultrasound part and the microbubble flow rate control part. The focused ultrasound part includes a focused ultrasound transducer and a power amplifier. The ultrasonic power amplifier with continuously adjustable frequency, power and action time drives the single-array concave sphe...

Embodiment 2

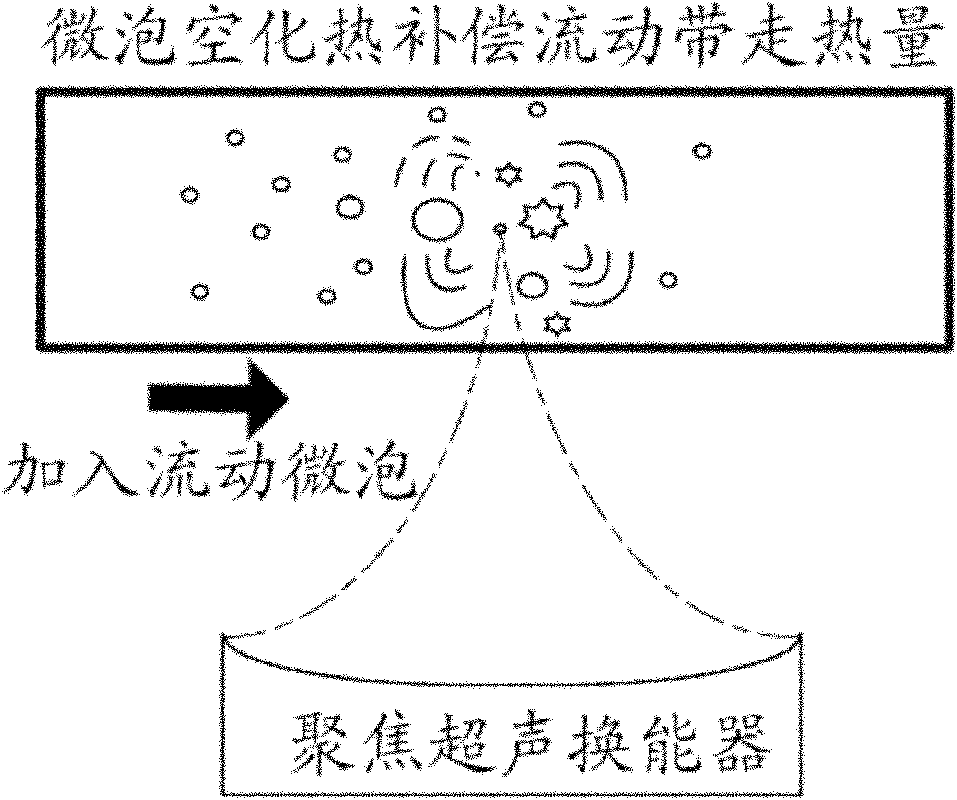

[0015] Embodiment 2: A method of using flow microbubble cavitation to generate additional heat to compensate the heat taken away by the fluid in a focused ultrasonic field, such as figure 2 shown.

[0016] In microbubble-assisted focused ultrasound hyperthermia, a transparent tissue imitation phantom through which microbubble solution can flow is used. The pipeline in the phantom is perpendicular to the sound axis of ultrasound treatment, and the focus of ultrasound treatment is adjusted in the pipeline by a three-dimensional moving device. The microbubble solution is injected into the pipeline, and the flow rate is controlled by the microbubble flow rate control pump. Afterwards, the focused ultrasound focal region is used to act on the target area, and the microbubble ultrasonic cavitation synergistic mechanism is used to generate additional heat, thereby compensating for the heat taken away by the flow and promoting the temperature increase near the pipeline.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com