Atomization device for cement grinding aid and using method thereof

A cement grinding aid and atomization device technology, which is applied in the direction of spraying devices, cement production, liquid spraying devices, etc., can solve the problem of not effectively eliminating the electrostatic adsorption of fine particles of cement and ball paste grinding, changing the dispersibility of materials in the mill Fluidity, low effective utilization rate of cement grinding aids and other problems, to reduce cement storage phenomenon, eliminate electrostatic adsorption and ball paste grinding phenomenon, optimize the effect of cement particle gradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with specific examples, but the present invention is not limited to the following examples.

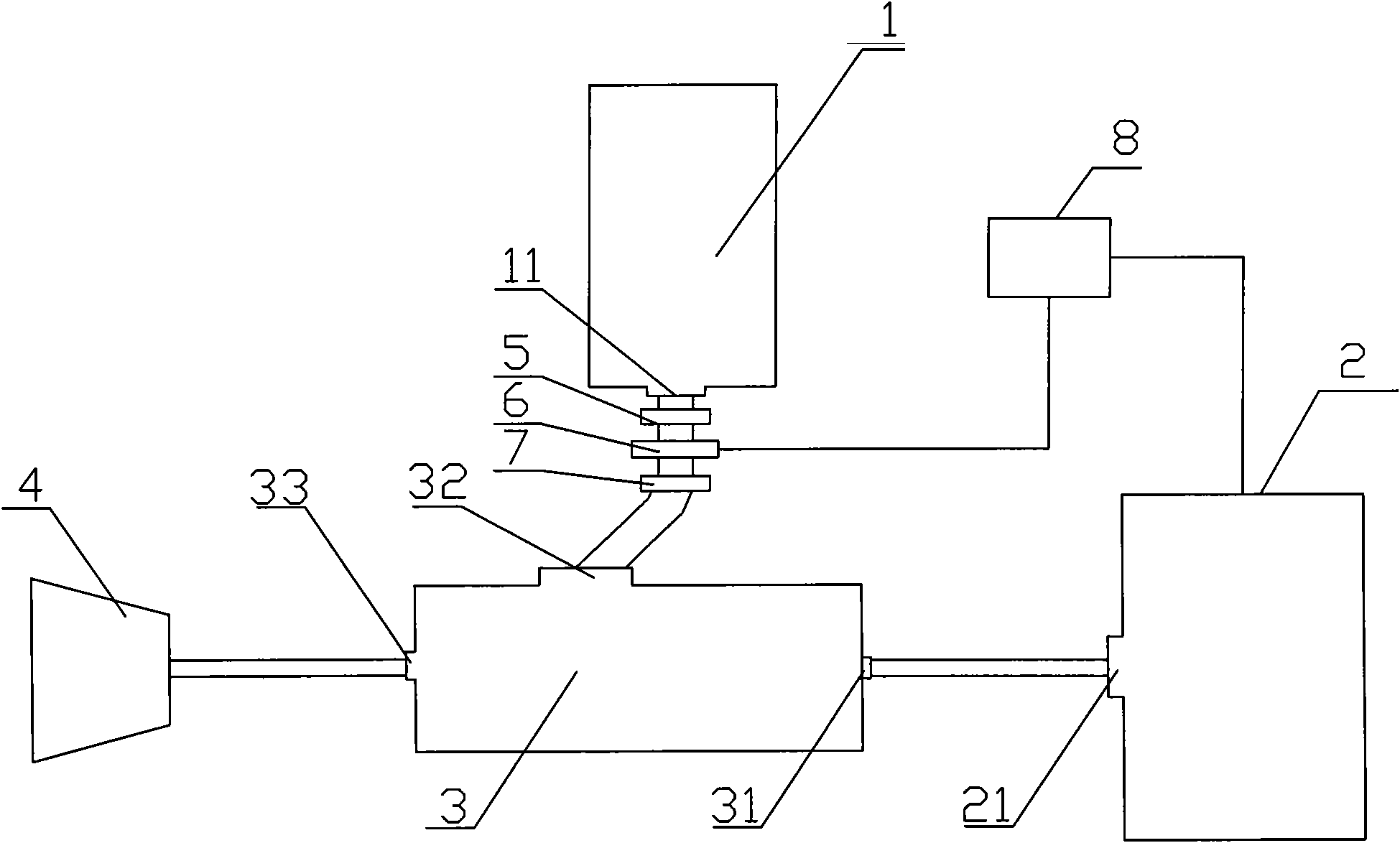

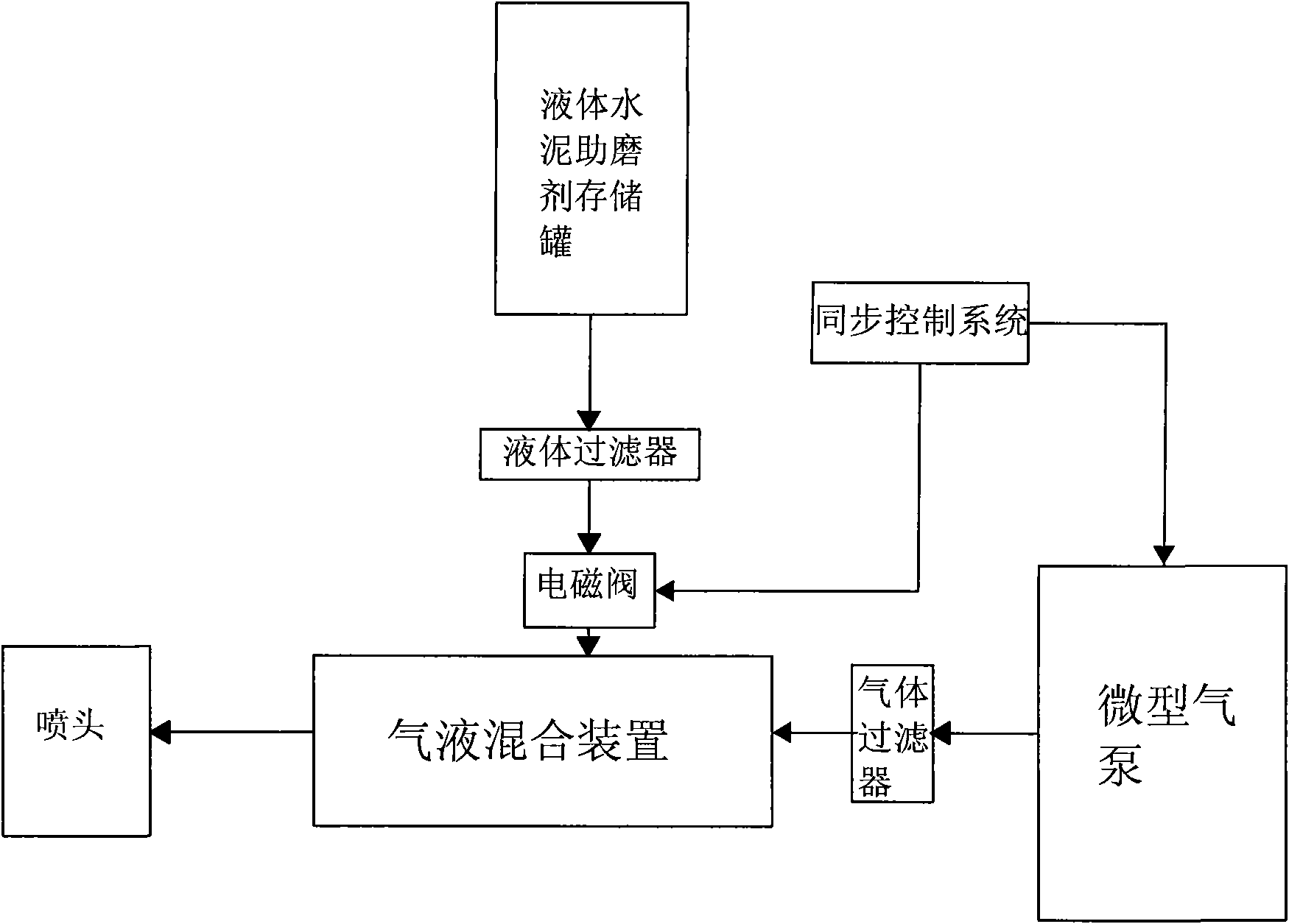

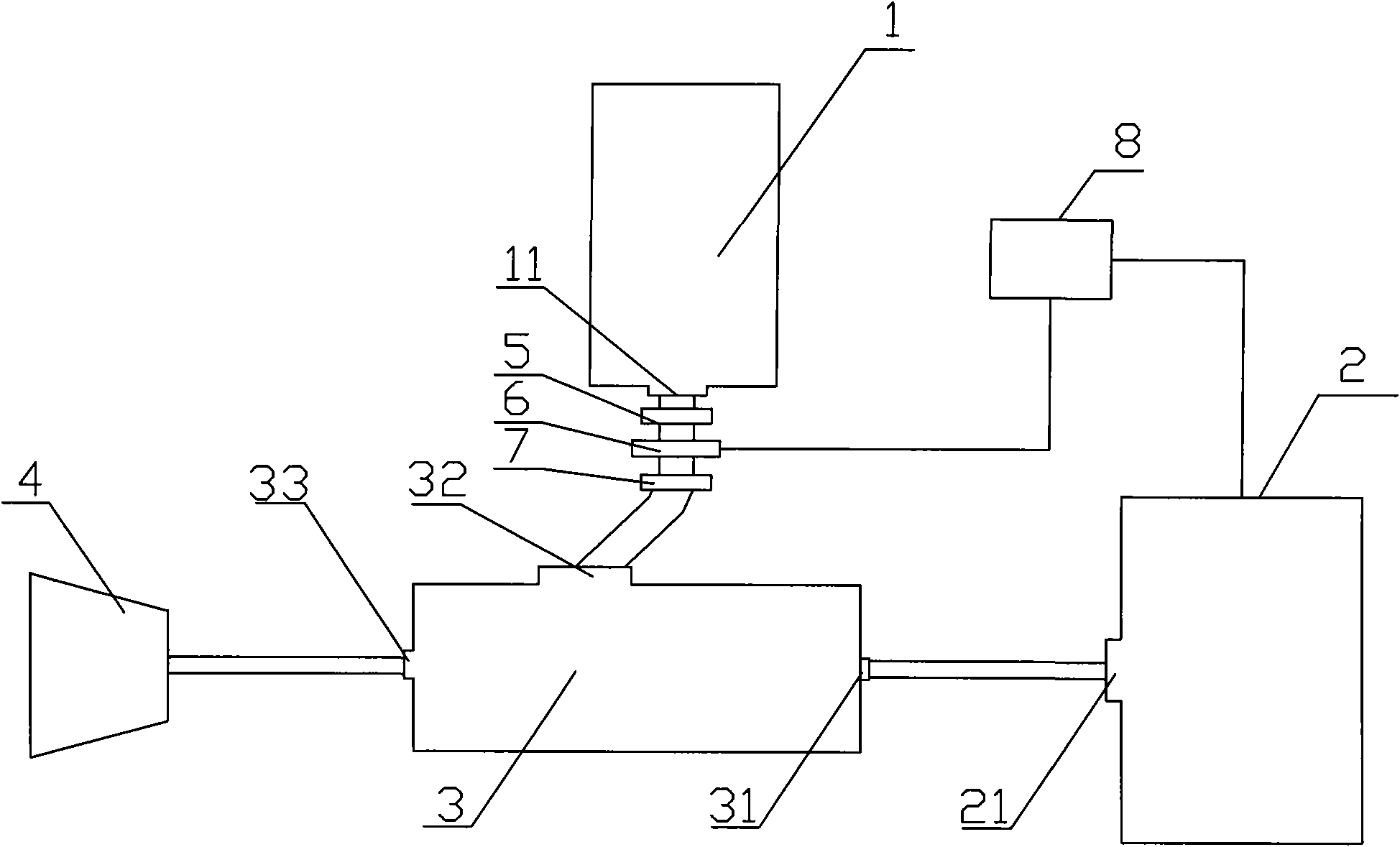

[0026] Such as figure 1 Shown, a kind of atomization device of cement grinding aid, it comprises liquid tank 1, air pump 2, gas-liquid mixing device 3, nozzle 4 and synchronous controller 8, the air outlet 21 of described air pump 2 is connected with gas-liquid mixing device 3 of the air inlet 31 is connected, the discharge port 11 of the liquid tank 1 is connected with the feed port (32) of the gas-liquid mixing device (3), the spray head (4) is connected with the gas-liquid mixing device (3) The discharge port (33) is connected, the electromagnetic valve 6 is arranged between the liquid tank 1 and the gas-liquid mixing device 3, to regulate the cement grinding aid flow and flow rate, the synchronous controller 8 is connected with the air pump 2 and the Solenoid valve 6 is connected.

[0027] For the conven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com