Design method for hob of cylindrical gear

A technology of cylindrical gear and design method, which is applied in the direction of gear tooth manufacturing tools, gear tooth manufacturing devices, and components with teeth, etc., which can solve the problems of difficult design, low machining accuracy, and difficult calculation, etc., and achieve convenient computer programming , The tooth shape is smooth and smooth, and the gear hobbing process is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

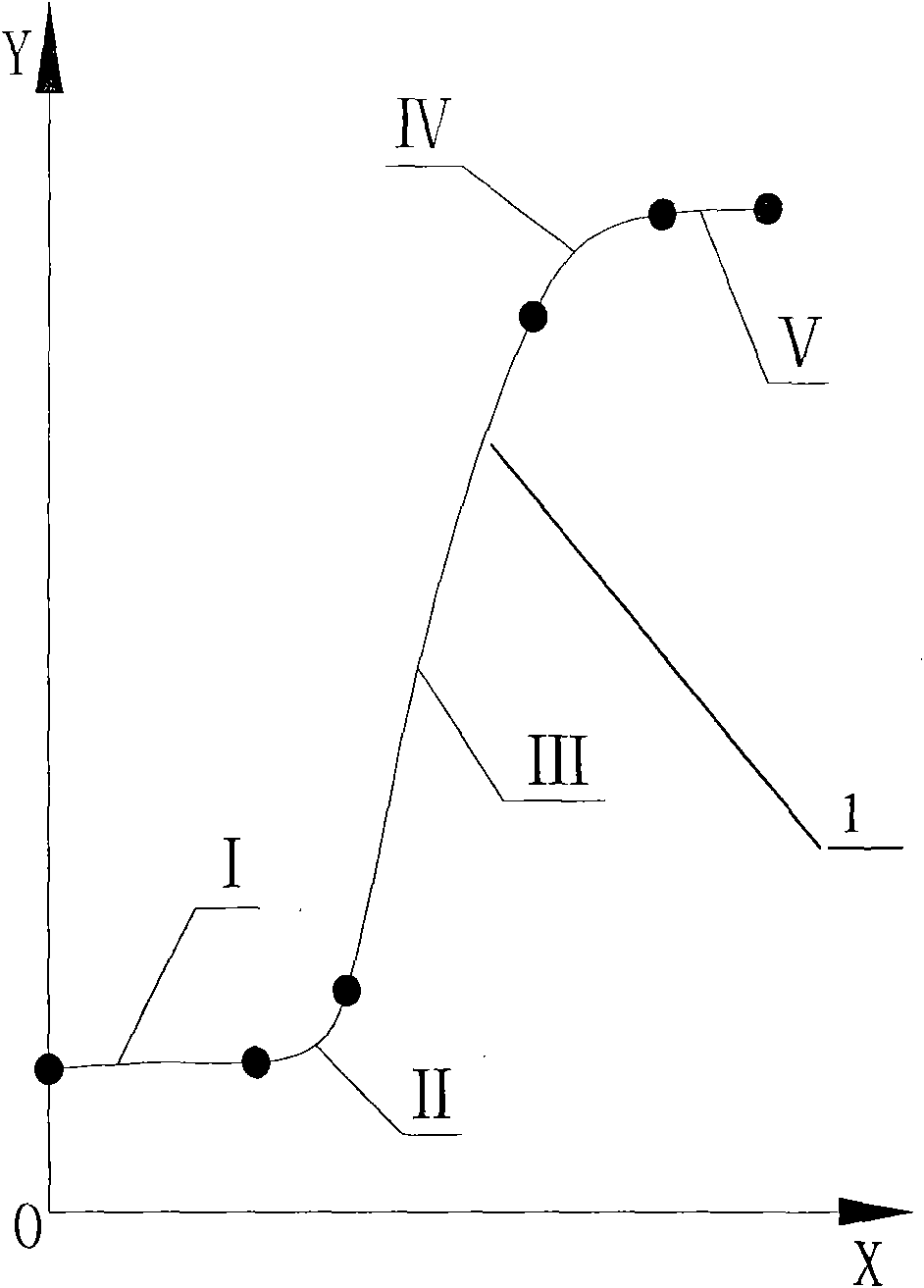

[0030] Such as figure 1 As shown, we first roughly segment the tooth shape point coordinates (1) given by the gear in the drawing, which can generally be divided into five curves: I, II, III, IV, V.

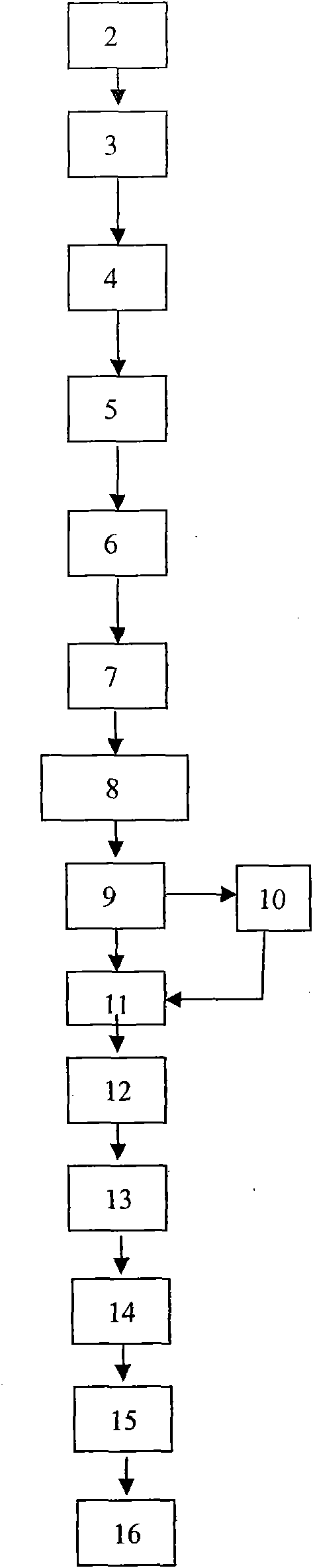

[0031] Such as figure 2 As shown, it is determined step by step according to the steps of the design flow chart figure 1 The coordinate points that should be included in each segment on the given tooth profile point coordinates (1) of the middle gear, that is, determine the decomposition points of each segment; at the same time, design the tooth profile of the hob cutter that processes each segment of tooth profile according to the steps point coordinates.

[0032] figure 1 Section I mentioned in the above is the set of points on the gear dedendum circle, section II is the set of points on the transition curve of the dedendum, section III is the set of working points, section IV is the set of point transition arc points on the tooth tip, and section V is the set of points on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com