Method for precisely measuring and processing profile of disc cam

A technology of contour measurement and disc cam, which is applied in the direction of measuring device, metal processing equipment, workpiece feed movement control, etc., can solve the problems of difficult operability, difficult selection of curve fitting method, complex cam master wheel profile, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

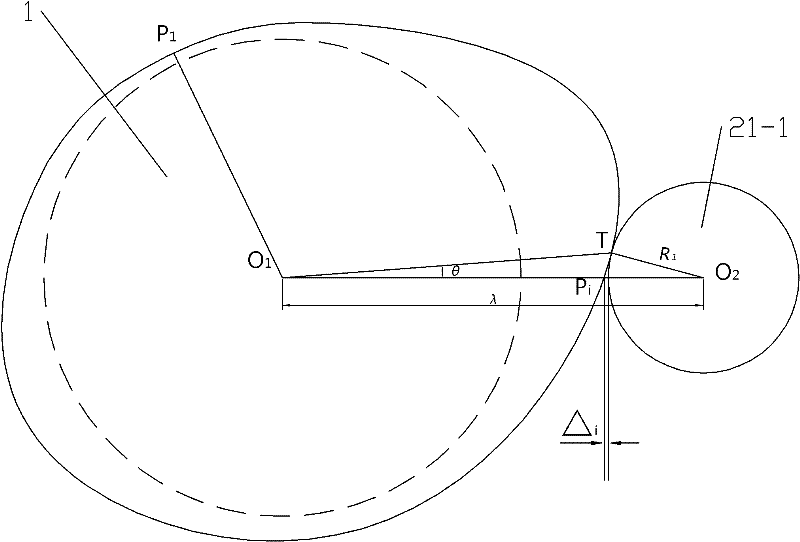

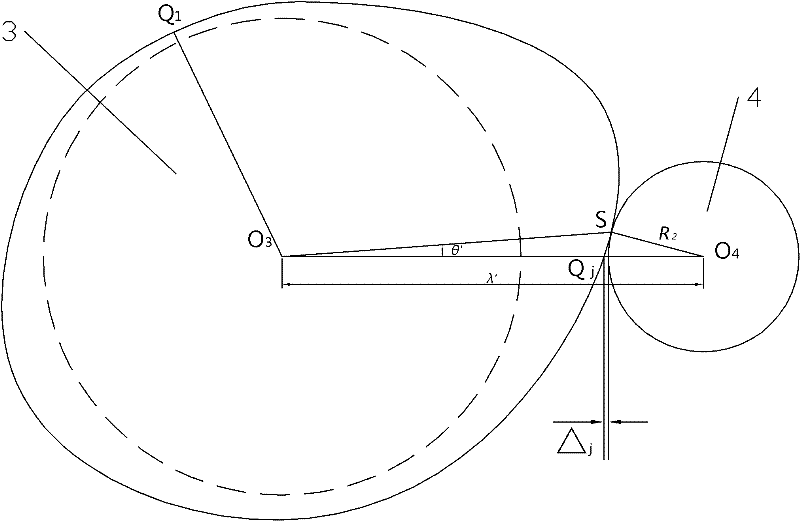

[0051] In order to obtain accurate disc cam profile data and process a cam with good synchronization with the cam master wheel (referred to as the master wheel), it is necessary to obtain the offset value of the contact point according to the radius of the measuring head or grinding wheel and eliminate it. For the measuring head, the approximate data of the real mother wheel profile is deduced according to the measured lift and angle of the mother wheel; for the grinding wheel, the data for processing is obtained according to the approximate data of the real mother wheel profile above, so that the final The processed cam is consistent with the mother wheel.

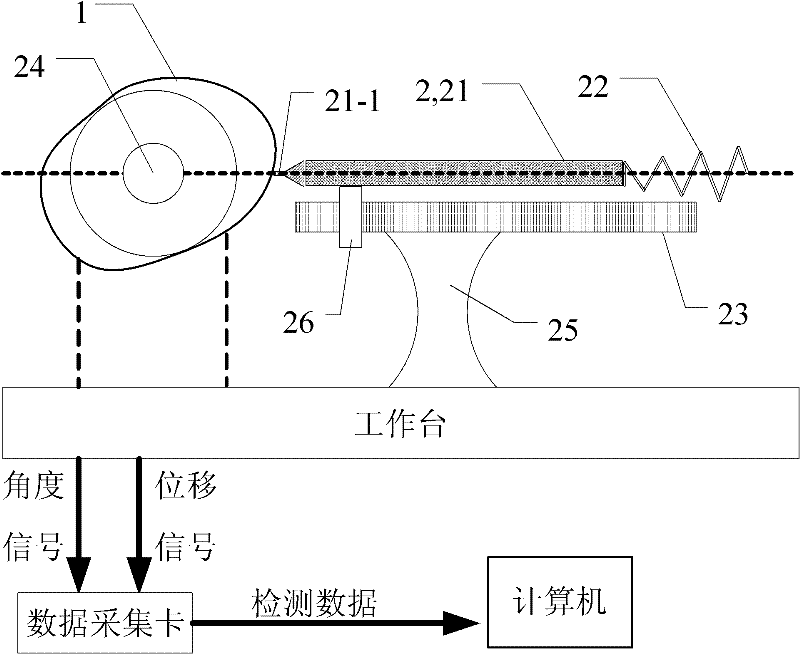

[0052] See Figure 4 , the method for carrying out accurate profile measurement and precise machining of disc cams in this embodiment includes the following steps:

[0053] ① The initial data of the discrete points of the master wheel profile are measured by the instrument.

[0054] See figure 1 , The cam precision mea...

Embodiment 2

[0083] In this embodiment, the cam of a certain type is sampled at an angle (ie α i ) The data measured at 0 degrees and 19.2 degrees are processed by the method of carrying out accurate profile measurement and precise machining of the disc cam obtained in embodiment 1.

[0084] By step 1. to 4. obtain the real approximation data of all discrete points of the parent wheel profile by the step of the method for embodiment 1, then by step 7. the real approximation data of the discrete points of the parent wheel profile are processed, obtain the following table 1 and The data in Table 2 (polar diameter ρ', grinding wheel radius R 2 and λ' are in millimeters).

[0085] Table 1. When the sampling angle is 0 degrees

[0086]

ρ'

θ'

angle α j

Grinding wheel

λ'

Radius R 2

106

0

0

25

131

106.0004

0.15

0.15

25

130.9985

106.0006

0.3

0....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com