Method for preparing 2-methylacraldehyde and 2-methyl-2-pentenal synchronously

A technology of methacrolein and pentenal, applied in chemical instruments and methods, preparation of carbon-based compounds, preparation of organic compounds, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

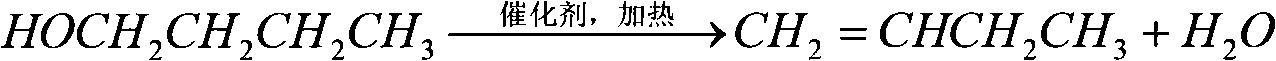

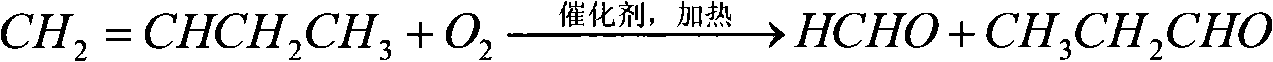

Problems solved by technology

Method used

Image

Examples

Embodiment 1

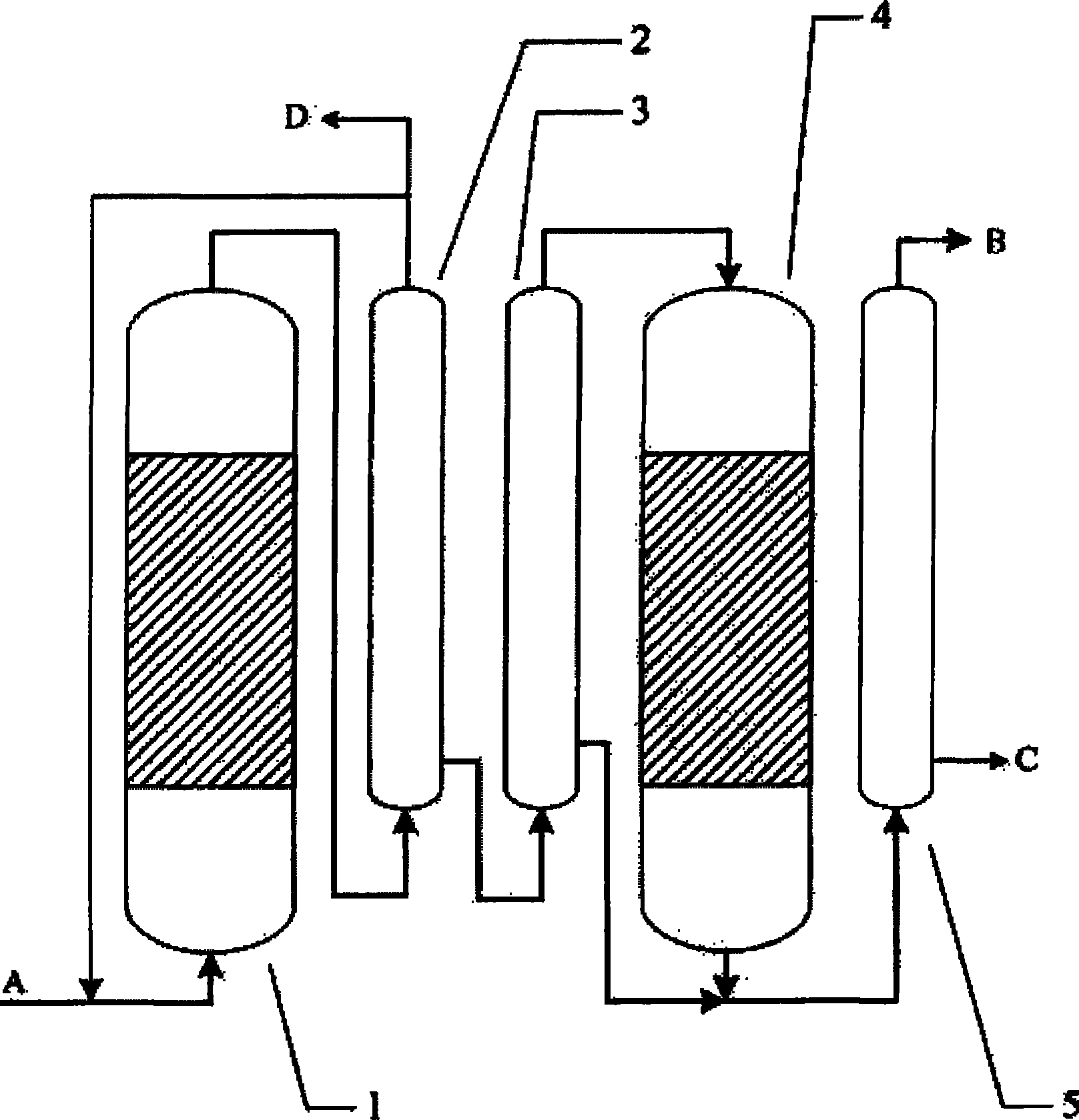

[0030] Such as figure 1 As shown, the mixed gas A of 1-butene / oxygen / water vapor / nitrogen = 5 / 1 / 0.3 / 4 (volume ratio) is preheated to 232°C, and passed into the oxidation reactor 1 at a total flow rate of 40L / min Oxidation reaction is carried out in the oxidation reactor 1, which is a stainless steel reaction tube with 2kg of catalyst, inner diameter of 25mm and height of 6.1m. Based on the total weight of the catalyst, the catalyst contains 6.7% Mo, 2.1% V, 1.1% K, 0.5% Ce, 0.03% P, 3.8% W, 15% Al, and the rest is Si. The content of each element in the catalyst mentioned above is the weight content calculated as the oxide of each element. Quartz sand is used as the diluent, the weight ratio of the catalyst and the diluent is 1:1, and the particle size of the catalyst and the quartz sand are both 2-4 mm. The temperature of the reaction tube is controlled at 250-260°C, and the reaction pressure is controlled at 0.3±0.02mPa.

[0031] The reaction product coming out of the oxid...

Embodiment 2

[0036] Such as figure 1 As shown, the mixed gas A of n-butanol / oxygen / water vapor / nitrogen=1 / 1 / 0.1 / 4 (volume ratio) is preheated to 232°C, and passed into the oxidation reactor 1 at a total flow rate of 90L / min Carry out oxidation reaction, oxidation reactor 1 is in a stainless steel reaction tube that 2kg catalyst is housed, inner diameter is 25mm, height 6.1m. Based on the total weight of the catalyst, the catalyst contains 6.7% Mo, 2.1% V, 1.1% K, 0.5% Ce, 0.03% P, 3.8% W, 15% Al, and the rest is Si. The content of each element in the catalyst mentioned above is the weight content calculated as the oxide of each element. Quartz sand is used as the diluent, the weight ratio of the catalyst and the diluent is 1:1, and the particle size of the catalyst and the quartz sand are both 2-4mm. The temperature of the reaction tube is controlled at 320-330°C, and the reaction pressure is controlled at 0.3±0.06mPa.

[0037] The reaction product coming out of the oxidation reactor 1 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com