Hydroxy propyl cellulose graft copolymer, preparation method and application thereof

A technology of hydroxypropyl cellulose and copolymer, which is applied in the field of hydroxypropyl cellulose graft copolymer and its preparation, can solve problems such as not being able to meet environmental protection, and achieve large specific surface area, large biological functionality, and diameter thickness uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

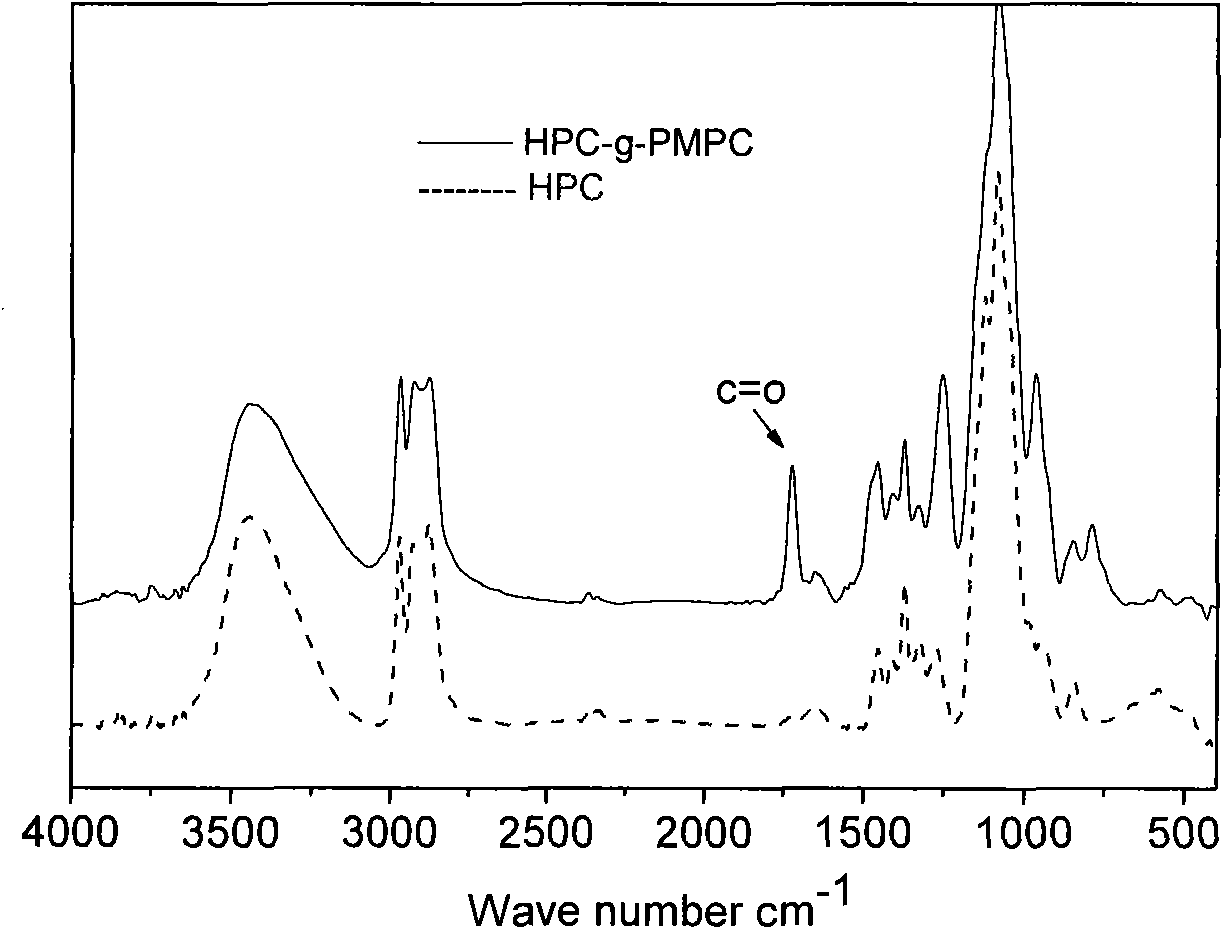

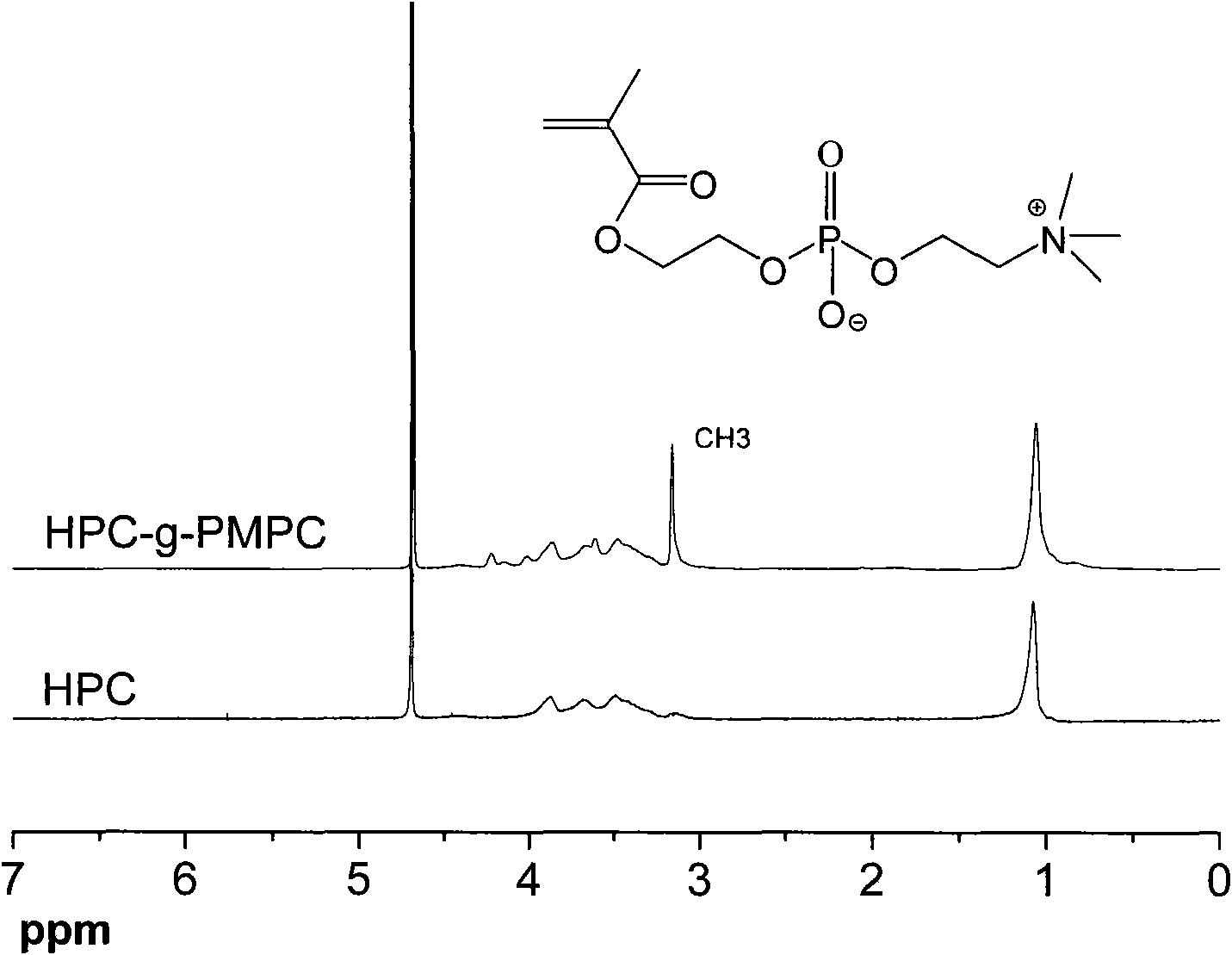

[0044] 1) Preparation of HPC-g-PMPC

[0045]In a 100ml single-necked bottle, add 50ml of twice distilled water and 0.5g of hydroxypropyl cellulose (purchased from Aldrich, USA, Mn=10 000, Mw=80 000), after fully dissolving, add 1ml of 0.5mol / L Cerium ammonium nitrate solution and nitric acid solution, nitrogen bubbling for 30 minutes, add 0.3g 2-methacryloyloxyethyl phosphorylcholine (purchased from Nanjing Letianran Science and Technology Development Institute), after sealing, place in a 30°C water bath After reacting for 3 hours, air was introduced to terminate the reaction, the reaction solution was put into a dialysis bag, and dialyzed in secondary water for 5 days to obtain a clear and transparent solution, which was freeze-dried to obtain the product with a yield of 60%, H 1 In the formula I detected by NMR, m=30, n=0.20.

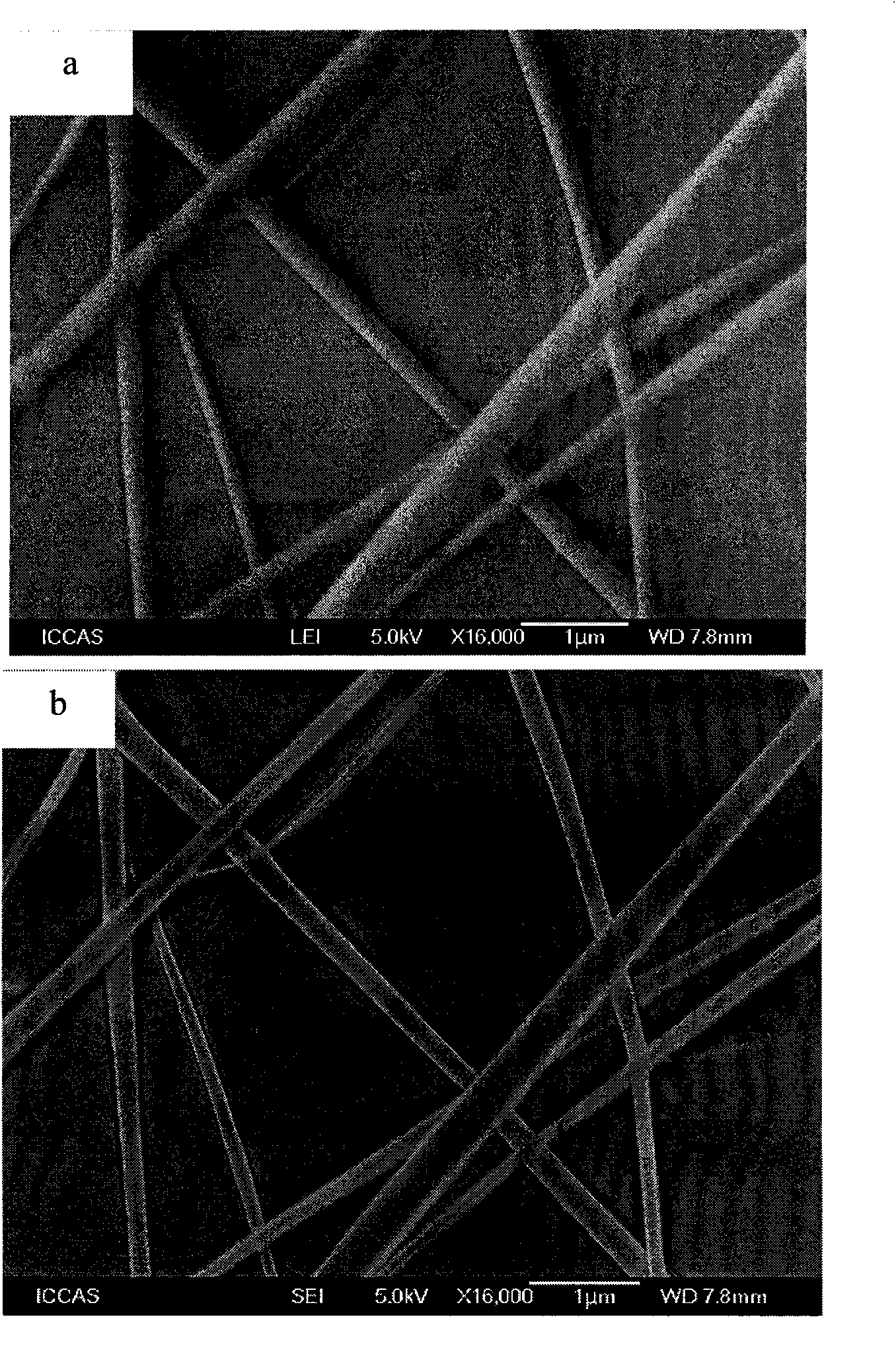

[0046] 2) Electrospinning

[0047] Dissolve 0.4 g of HPC-g-PMPC in 3 ml of methanol, stir evenly, and let stand to defoam to obtain HPC-g-PMPC spin...

Embodiment 2

[0049] 1) Preparation of HPC-g-PMPC

[0050] In a 100ml single-necked bottle, add 50ml of twice distilled water and 0.5g of hydroxypropyl cellulose (purchased from Aldrich, USA, Mn=10 000, Mw=80 000), after fully dissolving, add 1ml of 0.5mol / L Cerium ammonium nitrate solution and nitric acid solution, nitrogen gas bubbling for 30 minutes, 0.3g of 2-methacryloyloxyethyl phosphorylcholine was added, sealed, placed in a water bath at 30°C for 8 hours, and air was introduced to terminate the reaction. The reaction solution was put into a dialysis bag, and dialyzed in secondary water for 5 days to obtain a clear and transparent solution, which was freeze-dried to obtain the product with a yield of 82%, H 1 In formula I detected by NMR, m=30, n=0.51.

[0051] 2) Electrospinning

[0052] Dissolve 0.4 g of HPC-g-PMPC in 3 ml of methanol, stir evenly, and let stand to defoam to obtain HPC-g-PMPC spinning solution. Use a 10ml disposable syringe to extract the spinning solution, fix ...

Embodiment 3

[0054] 1) Preparation of HPC-g-PMPC

[0055] In a 100ml single-necked bottle, add 50ml double-distilled water and 0.5g hydroxypropyl cellulose (purchased from Aldrich, USA, Mn=100 000, Mw=80 000), after fully dissolving, add 1ml 0.5mol / L Cerium ammonium nitrate solution and nitric acid solution, nitrogen bubbling for 30 minutes, add 0.3g 2-methacryloyloxyethyl phosphorylcholine (purchased from Nanjing Letianran Science and Technology Development Institute), after sealing, place in a 30°C water bath After reacting for 3 hours, air was introduced to terminate the reaction, the reaction solution was put into a dialysis bag, and dialyzed in secondary water for 5 days to obtain a clear and transparent solution, which was freeze-dried to obtain the product with a yield of 65%. h 1 In formula I detected by NMR, m=300, n=0.22.

[0056] 2) Electrospinning

[0057] Dissolve 0.4 g of HPC-g-PMPC in 5 ml of methanol, stir evenly, and let stand for defoaming to obtain HPC-g-PMPC spinning...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com