Novel zwitterionic polyelectrolyte dispersing agent as well as method and application thereof

A zwitterion, polyelectrolyte technology, applied in chemical instruments and methods, dissolution, sulfonate preparation, etc., can solve problems such as poor stability, high price, environmental pollution, etc., and achieve good coverage and encapsulation effects, Increased repulsion, good chemical and thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

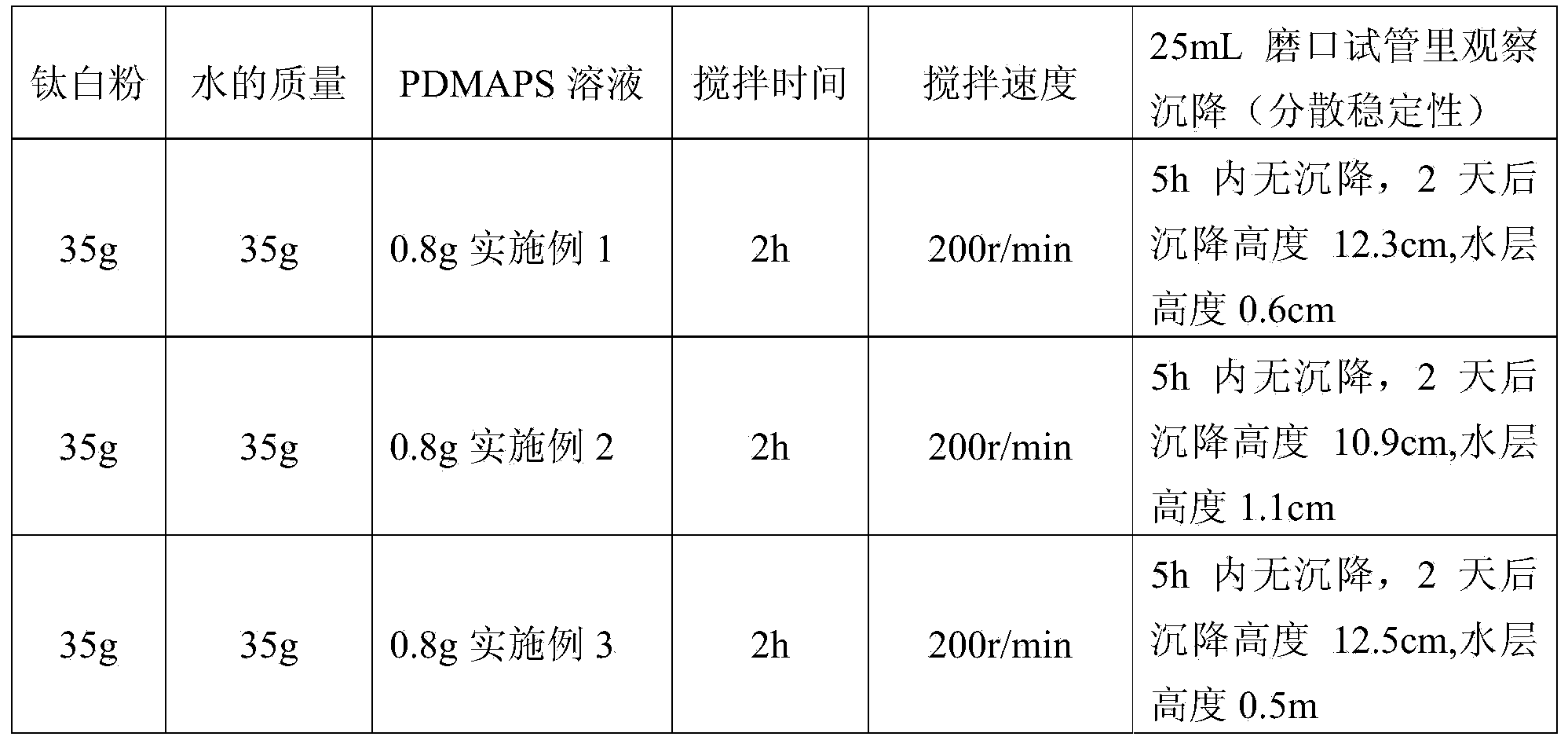

Examples

Embodiment 1

[0042] 1. Add 15.7g of dimethylaminoethyl methacrylate (DM), 55g of acetone, and 0.05g of hydroquinone (polymerization inhibitor) into a 250ml three-necked flask and stir and mix (stirring speed is 400r / min) to obtain a mixed Put it into an oil bath and heat it to 35°C and reflux to condense to prevent volatilization of acetone. Use a constant pressure leak to drop the acetone solution of 1,3-propane sultone ( This solution is composed of 12.2g of 1,3-propane sultone and 11.0g of acetone), reacted at 35°C for 24 hours, a large amount of white solids precipitated; filtered and washed the solids with acetone repeatedly for 5 times, dissolved in methanol, added Diethyl ether was recrystallized three times, and vacuum-dried at 50°C for 12 hours after suction filtration to obtain DMAPS.

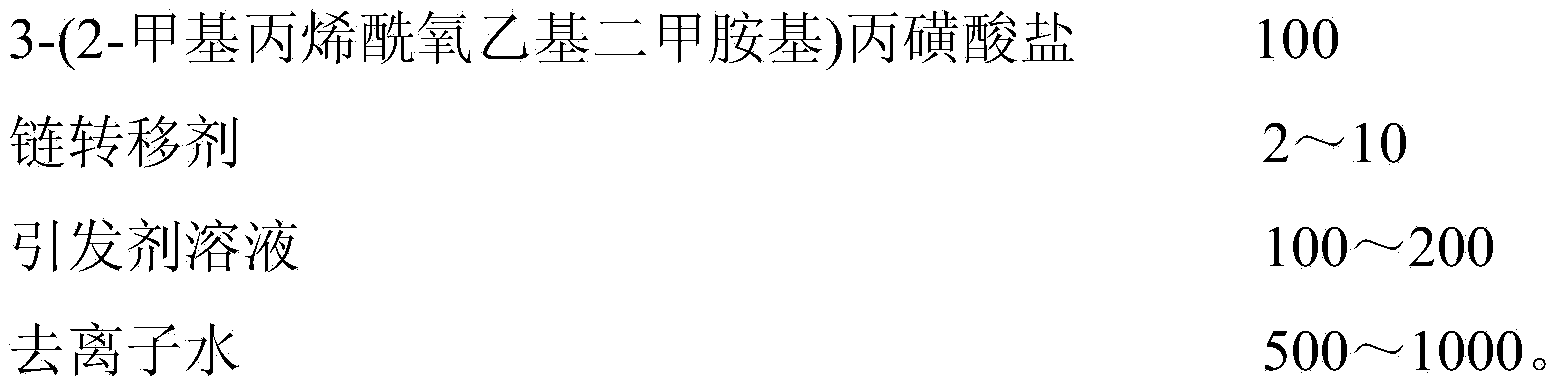

[0043] 2. Preparation of PDMAPS

[0044] In a 250mL four-neck flask equipped with a stirrer, a dropping funnel, and a reflux condenser, add 6g of DMAPS, 0.6g of sodium hypophosphite, and 30g of d...

Embodiment 2

[0046]1. Add 15.7g of dimethylaminoethyl methacrylate (DM), 55g of acetone, and 0.05g of hydroxyanisole (polymerization inhibitor) into a 250ml three-necked flask and stir and mix (stirring speed is 600r / min). Put it into an oil bath and heat it to 45°C and reflux to condense to prevent the volatilization of acetone; use a constant pressure leak to drip the acetone solution of 1,3-propane sultone into the flask at a speed of 12 s / drop (this solution consists of 12.2 g of 1,3-propane sultone and 12.2 g of acetone), reacted at 45°C for 18 hours, and a large amount of white solids precipitated; suction filtered and washed the solids 4 times with acetone, dissolved in ethanol, and recrystallized three times by adding ether , vacuum-dried at 60°C for 12 hours after suction filtration to obtain DMAPS.

[0047] 2. Preparation of PDMAPS

[0048] In a 250mL four-neck flask equipped with a stirrer, a dropping funnel, and a reflux condenser, add 6g of DMAPS, 0.3g of sodium hypophosphite...

Embodiment 3

[0050] 1. Add 15.7g of dimethylaminoethyl methacrylate (DM), 55g of acetone, and 0.05g of p-benzoquinone (polymerization inhibitor) into a 250ml three-necked flask and stir to mix (stirring speed is 300r / min), put it Heat to 55°C in an oil bath and reflux to condense to prevent volatilization of acetone; drip the acetone solution of 1,3-propane sultone (this solution consists of 12.2g Composed of 1,3-propane sultone and 13.4g of acetone), reacted at 55°C for 10 hours, a large amount of white solid precipitated; filtered with suction and washed the solid twice with acetone; dissolved in methanol, recrystallized by adding ether three times, After suction filtration, vacuum-dry at 40°C for 24 hours to obtain DMAPS.

[0051] 2. Preparation of PDMAPS

[0052] In a 250mL four-neck flask equipped with a stirrer, a dropping funnel, and a reflux condenser, add 6g of DMAPS, 0.12g of sodium hypophosphite, and 60g of deionized water, stir to dissolve (stirring speed is 600r / min), and hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com