Process for synthesizing sodium butyl xanthate

A technology of sodium butyl xanthate and synthesis process, which is applied in the field of synthesis process of sodium butyl xanthate to achieve good quality results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

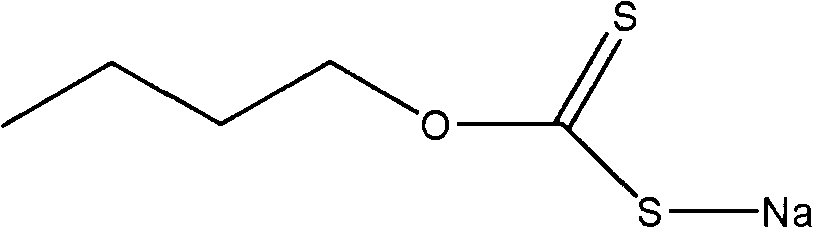

Image

Examples

Embodiment Construction

[0017] Processing step of the present invention is:

[0018] In a 250ml dry three-neck flask equipped with a stirring device, a thermometer, and a dropping funnel, add n-butanol and carbon disulfide, the molar ratio of the two is, n (n-butanol): n (carbon disulfide)=1: 1.0~1: 1.5 , and then add powdered NaOH in an amount of n(n-butanol):n(NaOH)=0.8:1~1.2:1, add solvent benzene, and react at 5~35°C for 0.5~1.5h.

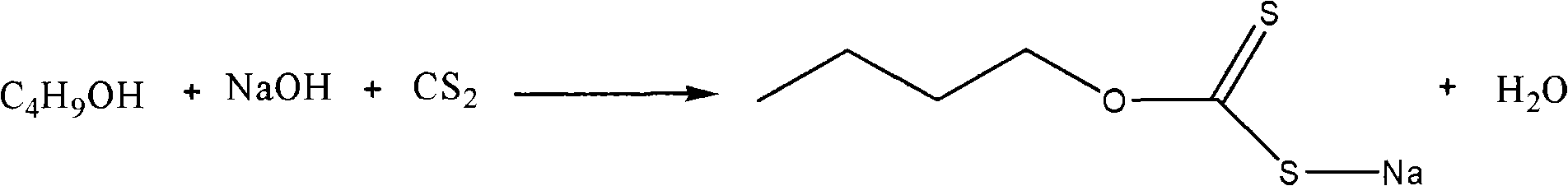

[0019] The reaction equation is:

[0020]

[0021] As a kind of preferred version, processing step of the present invention is:

[0022] n (n-butanol):n (sodium hydroxide):n (carbon disulfide)=1:1:1.05, the reaction temperature is 25-30°C, and the reaction time is 1h.

[0023] The present invention selects temperature of reaction, and reaction time is as the factor that influences the synthetic effect of sodium butyl xanthate, see table 1, table 2.

[0024] The influence of table 1 reaction temperature on yield

[0025] serial number

[0026] Note: n ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com