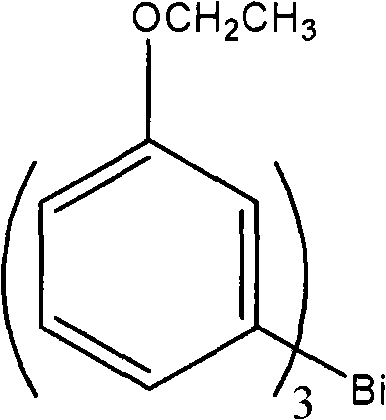

Method for synthesizing tri(m-ethoxyphenyl)bismuthine

A technology of ethoxyphenyl bismuth and a synthesis method, which is applied in the direction of bismuth organic compounds, etc., can solve the problems of unindustrialized production, etc., and achieve the effect of easy post-processing and few steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Method steps of the present invention are:

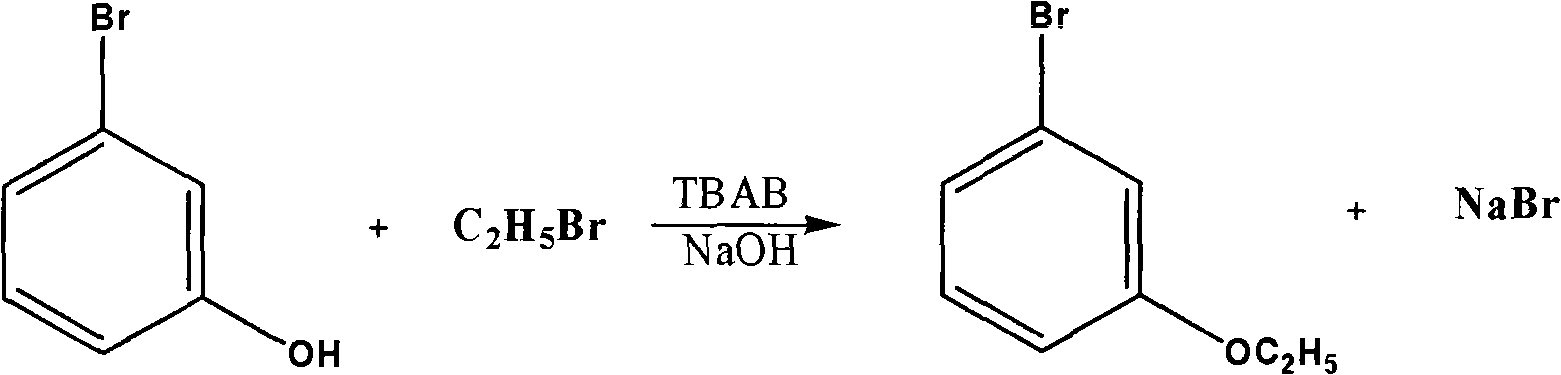

[0023] 1. Synthesis of m-bromophenetole

[0024] Add the sodium hydroxide of 30ml water and 0.15mol in the 100ml three-neck flask that electric stirrer, reflux condenser and dropping funnel are housed, then add m-bromophenol and tetrabutylammonium iodide, and the addition is, n( m-bromophenol): n (sodium hydroxide) = 2: 3 ~ 1: 1, n (tetrabutylammonium iodide): n (sodium hydroxide) = 0.04: 1 ~ 0.06: 1, at 60 ~ 80 ° C Add 5-10 ml of bromoethane under stirring; after reacting for 2-2.5 hours, cool, separate the organic phase, and extract the water phase with ether; combine the organic phases and wash with 10% NaOH solution, then wash with water until neutral, and use Dry with anhydrous sodium sulfate; evaporate the solvent, then distill under reduced pressure, collect the fraction at 130-135°C to obtain colorless liquid m-bromophenetole;

[0025] The reaction equation is:

[0026]

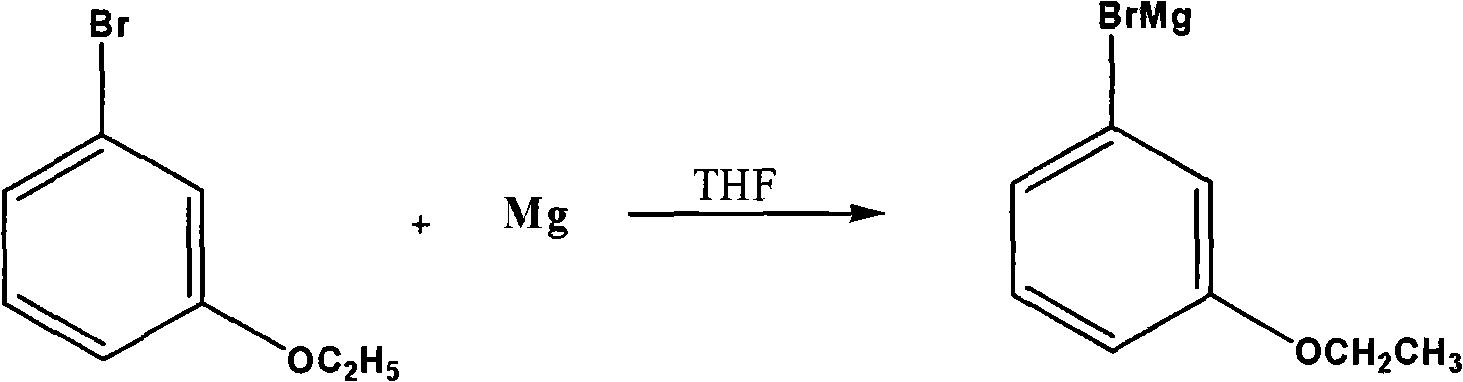

[0027] 2. Synthesis of m-ethoxyphenylmag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com